Anticorrosion coating material

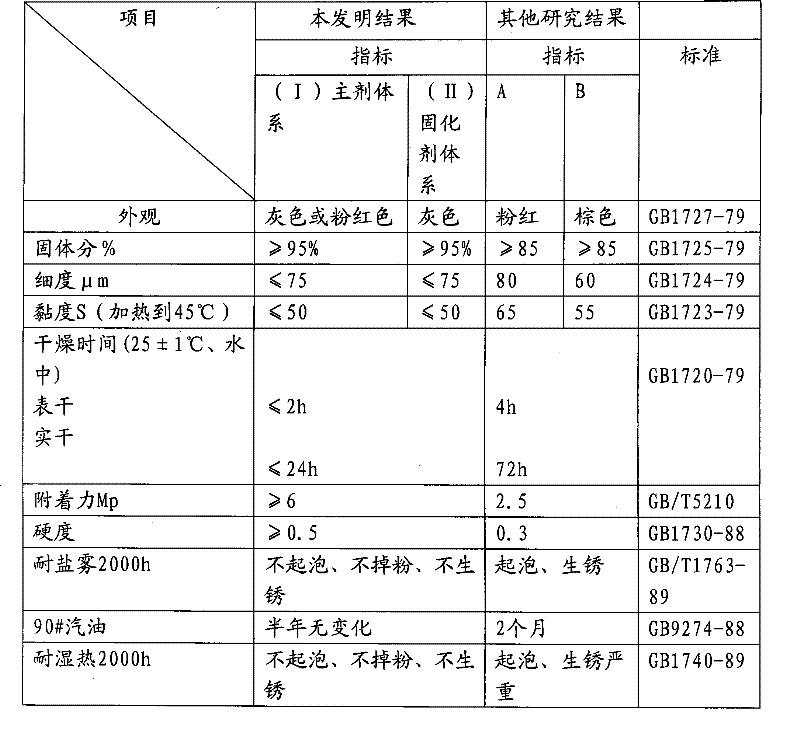

An anti-corrosion coating and coating material technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of inability to use steel structure anti-corrosion repair, harsh construction requirements, high prices, etc., and achieve good social and economic benefits. , The effect of reducing construction costs and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

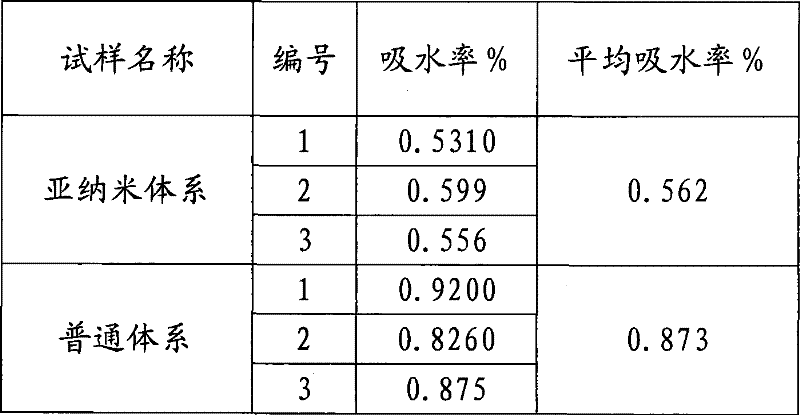

Method used

Image

Examples

Embodiment 1

[0033] A heavy-duty anti-corrosion coating material for steel structures in the ocean splash zone, including a main agent system and a curing agent system, in parts by weight:

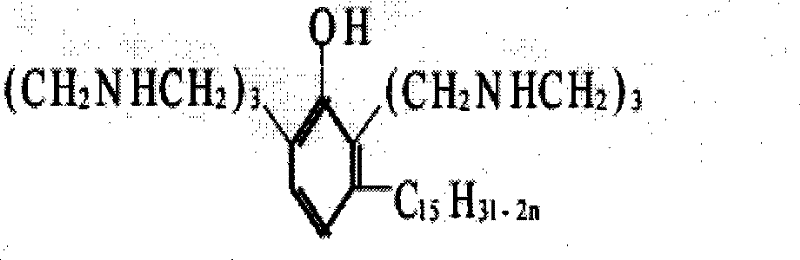

[0034] (1) Each component in the main agent system is: film-forming resin: bisphenol A type epoxy resin 50; Modified toughening agent: dibutyl phthalate 8; Defoamer: 0571.0 of BYK; Leveling agent: BYK’s 37771.0; Rust stabilizer: Zinc phosphate 8; Rust conversion agent: Diphenylguanidine chromate 0.4; Sub-nano flaky filler: Ceramic powder with a fineness of less than 1 micron 15; Inorganic cementitious material: Portland cement: 30; adhesion enhancer: epoxy phosphate 4;

[0035] (II) The components in the curing agent system are: curing agent: cashew nut shell oil modified phenalkamine 40; high wear-resistant filler: quartz powder 30; antirust pigment: mica iron oxide 25; penetrating agent fatty alcohol polyoxyethylene Ether 2; Organic Chelating Agent: Organic Phosphite 3.

[0036] When using, mix the...

Embodiment 2

[0038] A heavy-duty anti-corrosion coating material for steel structures in the ocean splash zone, including a main agent system and a curing agent system, in parts by weight:

[0039] (1) Each component in the main agent system is: Film-forming resin: bisphenol A type epoxy resin 45; Modified toughening agent: Cardolite lite202015; Defoamer: 0571.5 of Bi Ke Company; 37771.6 of Ke Company; rust stabilizer: zinc phosphate 4, zinc chromate 2; rust conversion agent: diphenylguanidine chromate 0.9; sub-nano flaky filler: talcum powder 15 with a fineness of 0.7 microns; inorganic cementitious material: aluminum Salt cement 40; adhesion enhancer: 1211 adhesion enhancer 3;

[0040] (II) The components in the curing agent system are: curing agent: cashew nut shell oil modified phenalkamine 45; high wear-resistant filler: quartz powder 30; antirust pigment: iron phosphorus powder 22; penetrating agent: fatty alcohol polyoxygen Vinyl ether 3; organic chelating agent: organic phosphite ...

Embodiment 3

[0043] A heavy-duty anti-corrosion coating material for steel structures in the ocean splash zone, including a main agent system and a curing agent system, in parts by weight:

[0044] (1) Each component in the main agent system is: film-forming resin: bisphenol A type epoxy resin 30; Modified toughening agent: dibutyl phthalate 12; Defoamer: 0572.0 of BYK; Leveling agent: BYK's 37771.5; Rust stabilizer: Zinc chromate 10; Rust conversion agent: Diphenylguanidine chromate 1.0; Sub-nano flaky filler: Ceramic powder with a fineness of less than 1 micron 12; Inorganic cementitious material : Sulphoaluminate cement 30; adhesion enhancer: epoxy phosphate 4;

[0045] (II) The components in the curing agent system are: curing agent: Cardolite XN200730; high wear-resistant filler: quartz powder 25; anti-rust pigments: mica iron oxide 15, phosphorus iron powder 8; penetrant fatty alcohol poly Oxyethylene ether 1; organic chelating agent: organic phosphite 3.

[0046] When using, mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com