Photosynthesis microorganism fuel cell

A technology of photosynthetic microorganisms and fuel cells, applied in biochemical fuel cells, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of not being able to directly use convenient and easy-to-get solar energy, and achieve improved solar energy utilization, Good for growth and reproduction, simple battery structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The microorganisms are Chlorella vulgaris, cultured from water samples obtained from the river, and separated by the water droplet separation method. The medium composition (1L) is as follows:

[0035] Table 1 Medium formula table (1L)

[0036]

[0037] Table 2 Trace element formula of culture medium (1L)

[0038]

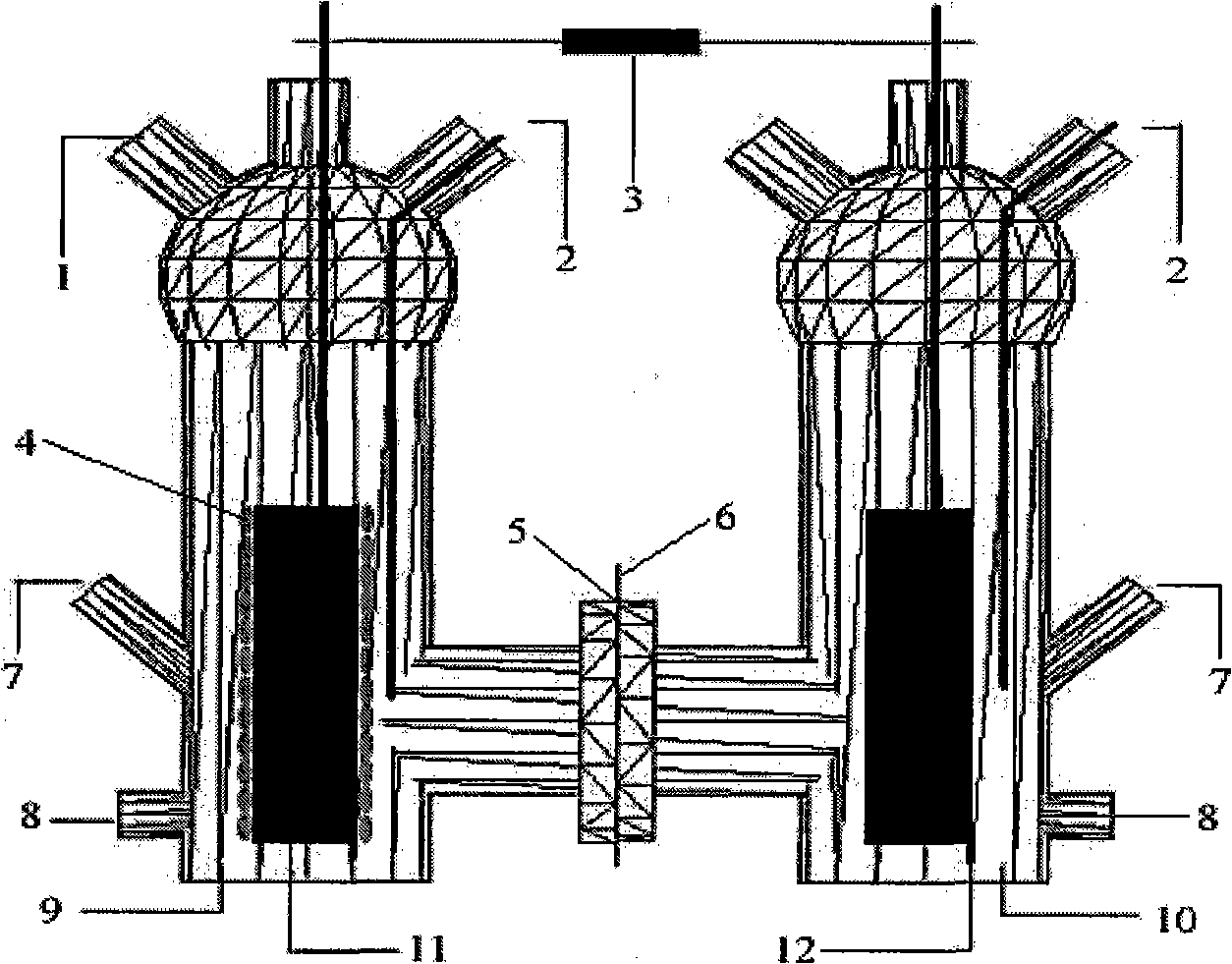

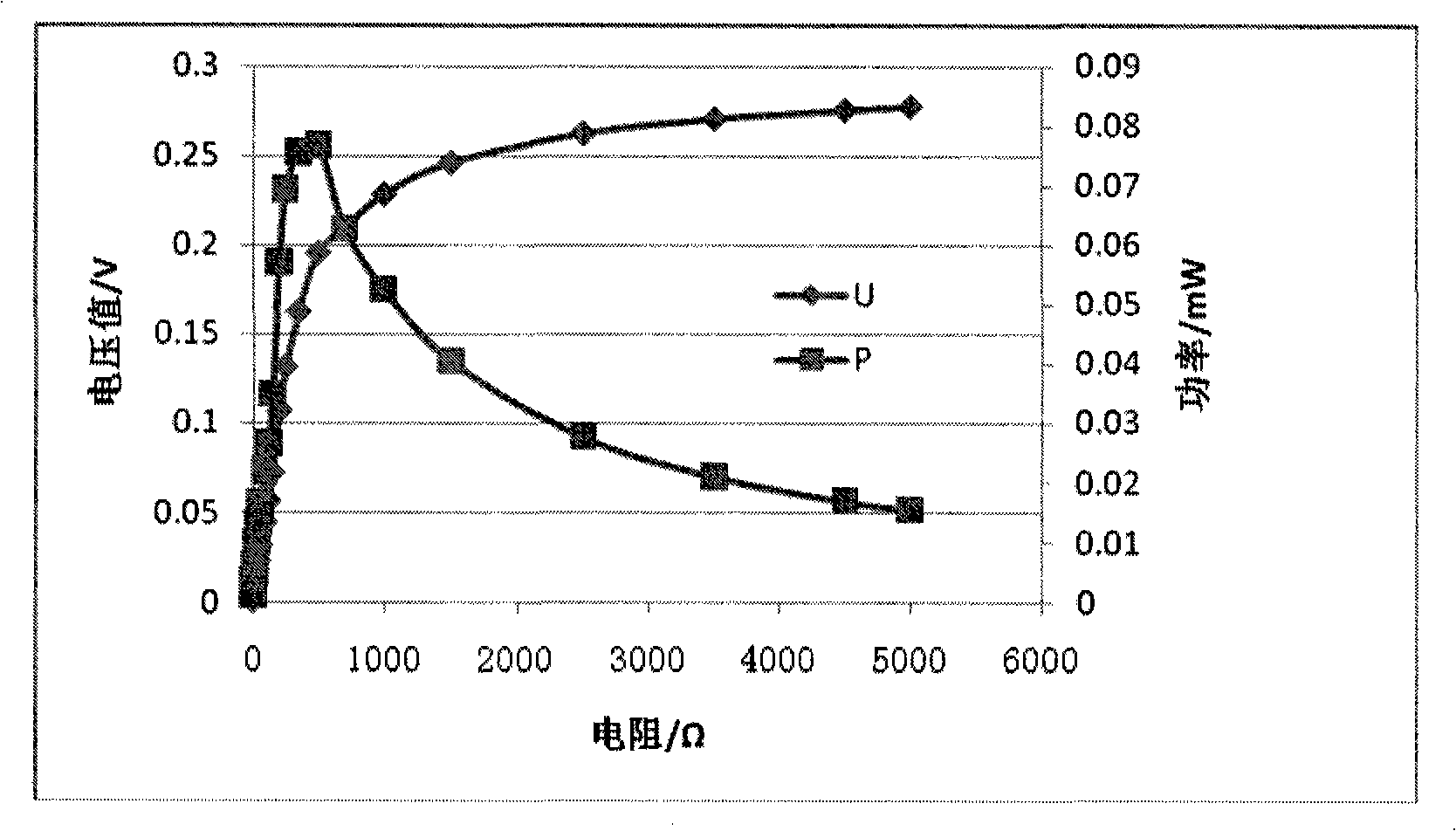

[0039] The photosynthetic microbial fuel cell consists of two electrode chambers, the cathode and the anode, which are connected by a proton exchange membrane (Nation-17, Dupont). 1000ml solution, the physical surface area of the anode plate is 75cm 2 , add anode buffer solution (Table 3) and the above-mentioned culture medium to the anode chamber, and add cathode buffer solution (Table 4) and potassium ferricyanide solution to the cathode chamber. All devices were placed in a light incubator for experiments. The growth temperature is 25-30°C, and the light intensity is 4.5×10 3 lx, the load resistance is determined to be 510Ω.

[0040] Table 3...

Embodiment 2

[0046] Photosynthetic bacteria (photosynthetic bacteria referred to as PSB) were isolated in Xiaoyuehe, Beijing, and the medium used for isolation was: organic matter 1.5-2g, (NH 4 ) 2 SO 4 1g, NaCl 2g, NaCO 3 5g,K 2 HPO 4 0.5g, MgSO 4 ·7H 2 O0.2g, distilled water 1000mL, pH 7.0, culture at 25-30°C under light. The isolated PSB has a Gram-negative reaction and is single-cell egg garden and spherical. The colony is rose red, moist and smooth, and the liquid culture of the bacteria is dark red. The bacterial suspension after liquid culture contains 2.6- 280 million / mL, identified as Rhodobacter sphaeroides, Rhodobacter palustris, Rhodobacter Capsulatus, Rhodospirillum rubrum and other strains.

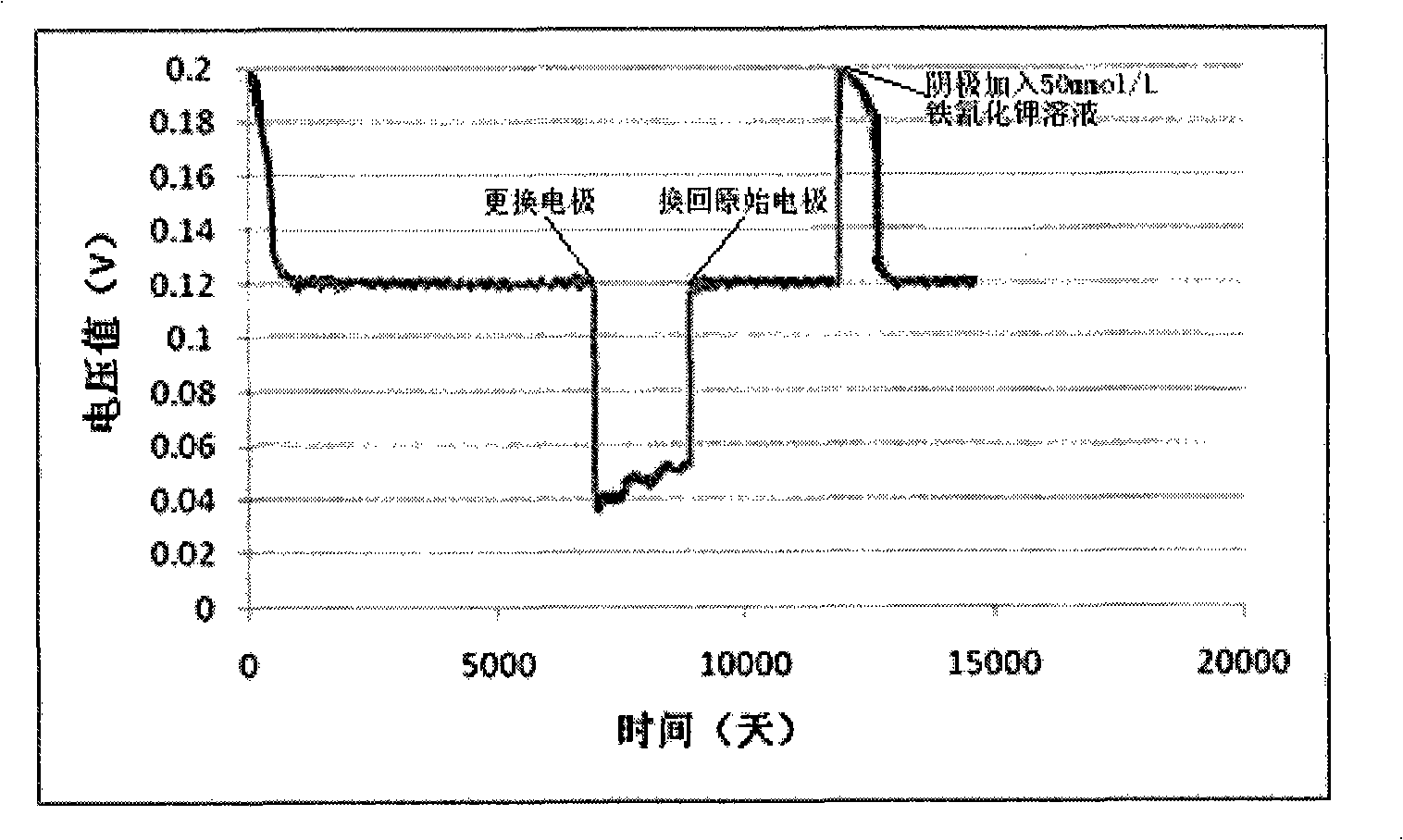

[0047] The photosynthetic microbial fuel cell consists of two electrode chambers, the cathode and the anode, which are connected by a proton exchange membrane (Nation-117, Dupont). A vacuum pad is sandwiched between the proton exchange membrane and the bipolar chambers to keep ...

Embodiment 3

[0050] The photosynthetic microorganism is Spirulina, using Zarrouk's medium, adding 150mL of culture medium into a 250mL Erlenmeyer flask, and inoculating Spirulina in the logarithmic growth phase. To about 10, THZ-82 constant temperature shaker shaker 30 ℃, 24h d -1 Light shake flask culture.

[0051] The photosynthetic microbial fuel cell consists of two electrode chambers, the cathode and the anode, which are connected by a proton exchange membrane (Nation-117, Dupont). A vacuum pad is sandwiched between the proton exchange membrane and the bipolar chambers to keep it sealed. Each electrode chamber is filled with 1000ml solution. The physical surface area of the anode plate is 120cm 2 , add anode buffer (Table 3) and Zarrouk's medium to the anode chamber, and add cathode buffer (Table 4) to the cathode chamber. All devices were placed in a light incubator for experiments. The growth temperature is 25-30°C, and the light intensity is 4.7×10 3 lx, the load resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com