Preparation of yellow copper CIG selenide or sulfide semiconductor thin film material

A technology of chalcopyrite and thin-film materials, which is applied in the field of preparation of selenide or sulfide semiconductor thin-film materials, can solve the problems of little improvement in selenization or vulcanization effect, difficulty in controlling the partial pressure atmosphere, and high post-selenization temperature. Achieve the effects of improving selenization/sulfurization efficiency, saving material consumption, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

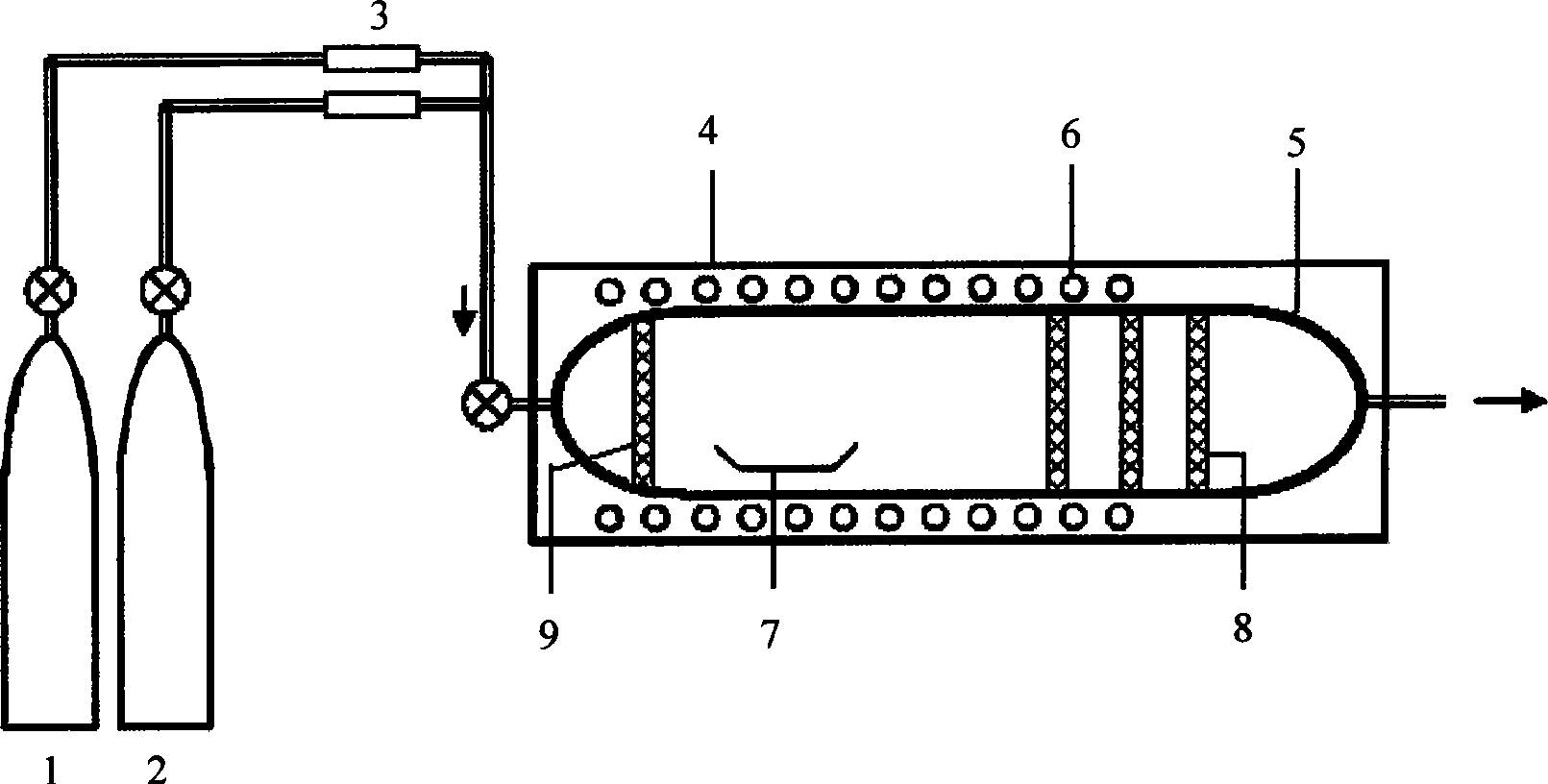

[0031] figure 1 Provide the structural representation of the gas-solid reaction chamber that the embodiment of the present invention adopts, wherein: 1—N 2 / Ar gas source, 2—H 2 Gas source, 3—mass flow meter MFC, 4—stainless steel outer body, 5—gas-solid reaction chamber, 6—resistance heating wire, 7—selenium (sulfur) evaporation source, 8—end heating wire mesh, 9—front heat silk screen.

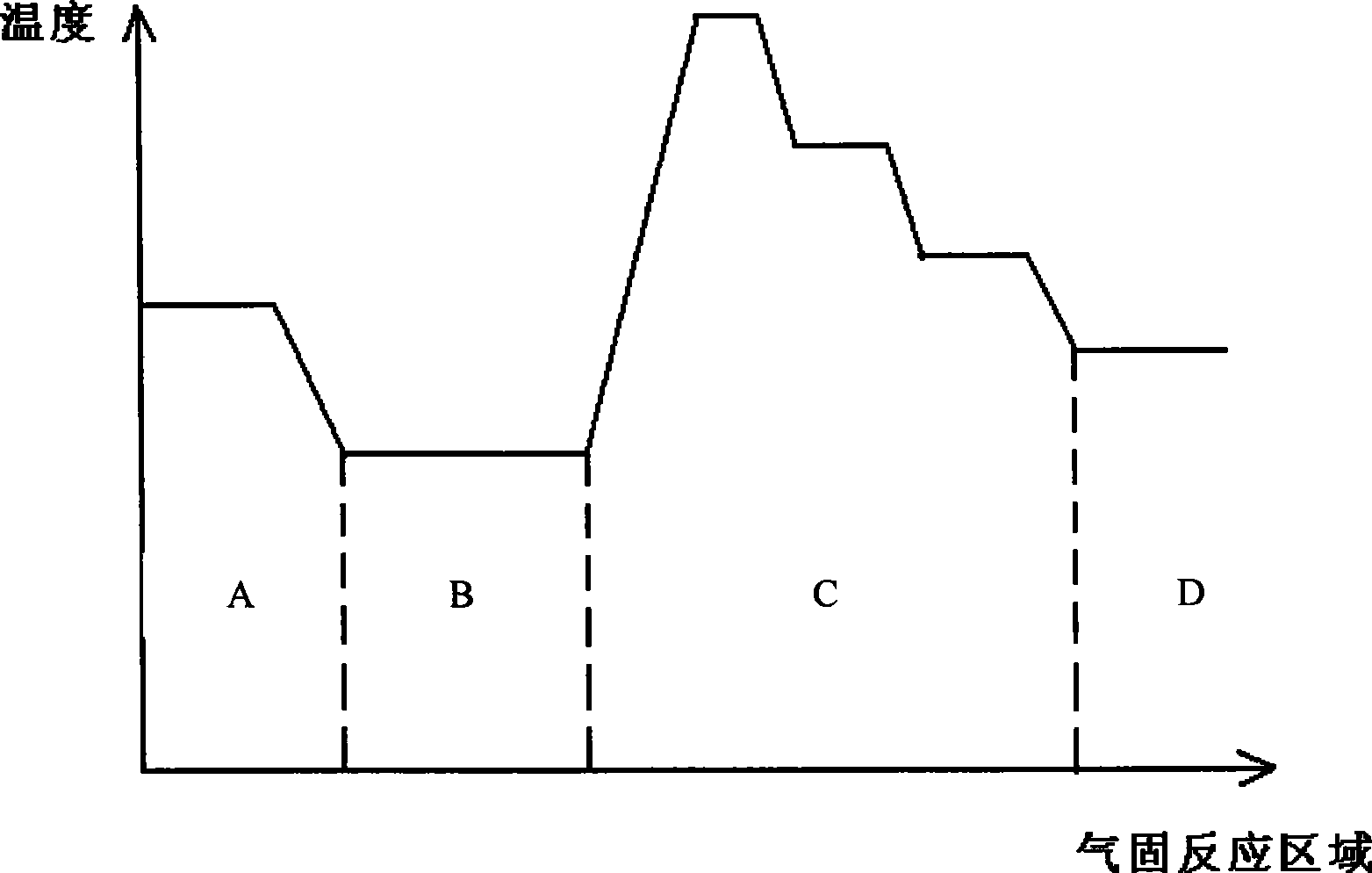

[0032] First use vacuum magnetron sputtering, heating evaporation or chemical water bath electrodeposition method to deposit Cu, In and Ga metal prefabricated layers with chemical formula ratio step by step on the soda lime glass Mo substrate, and then put it into the selenization / sulfurization reaction furnace . Use a vacuum pump to pre-pump the gas-solid reaction chamber and the selenization / sulfurization reaction furnace. After reaching the preset vacuum degree, close each valve. Connect all heating systems in the system, specifically: (1) heat the CIG metal prefabricated layer to 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com