Method for preparing silicon carbide whisker by laser irradiation of nano silicon carbide powdered material

A nano-silicon carbide and silicon carbide whisker technology, applied in the nanometer field, can solve the problems of catalyst affecting purity, high raw material price, and high raw material cost, and achieve the effects of short preparation cycle, good whisker quality, and simple implementation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

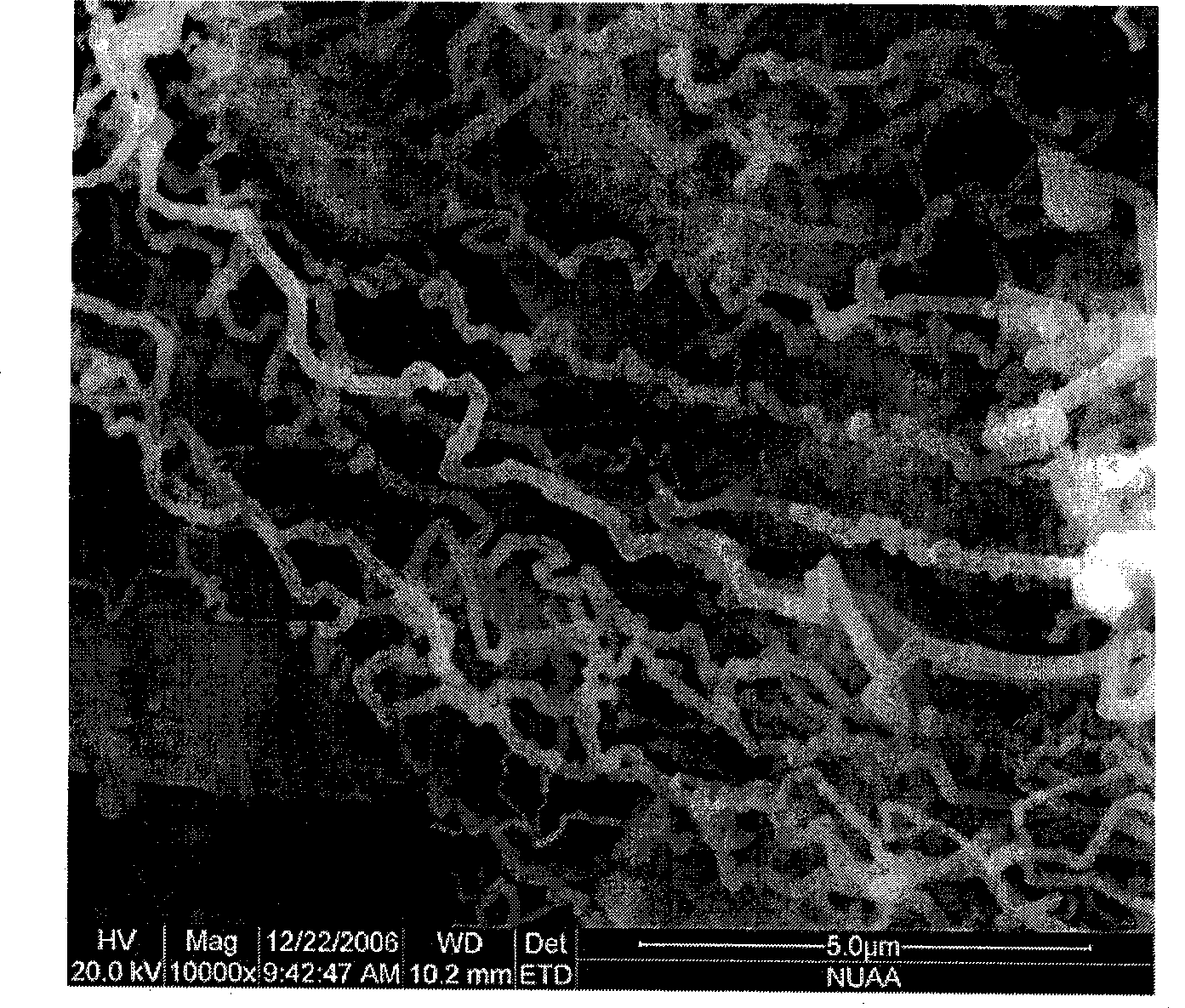

[0027] Embodiment 1: prepare one of nano-SiC whiskers

[0028] The nano-SiC whiskers prepared in this embodiment adopt PVA (polyvinyl alcohol) binder.

[0029] Steps:

[0030] In the first step, PVA (polyvinyl alcohol) is dissolved in hot water to make a 5% PVA solution, and kept in a high-temperature furnace (80° C.) for 1 day so that PVA can be fully dissolved in hot water.

[0031] In the second step, take 30g of nano-SiC powder and put it into a beaker, take 5ml of 5% PVA (polyvinyl alcohol) solution and pour it into the beaker, stir evenly, put it in a dryer to dry, take it out and stir evenly, and add it to the mold cavity.

[0032] The third step is to use the principle of cold isostatic pressing to apply pressure P (8MPa) to the mold (diameter 40mm, thickness 3mm), and keep the pressure for 2 minutes, and the cylinder block with a diameter of 40mm and a thickness of 3mm can be demolded Nano-SiC briquettes, and the size of the briquettes does not affect the preparati...

Embodiment 2

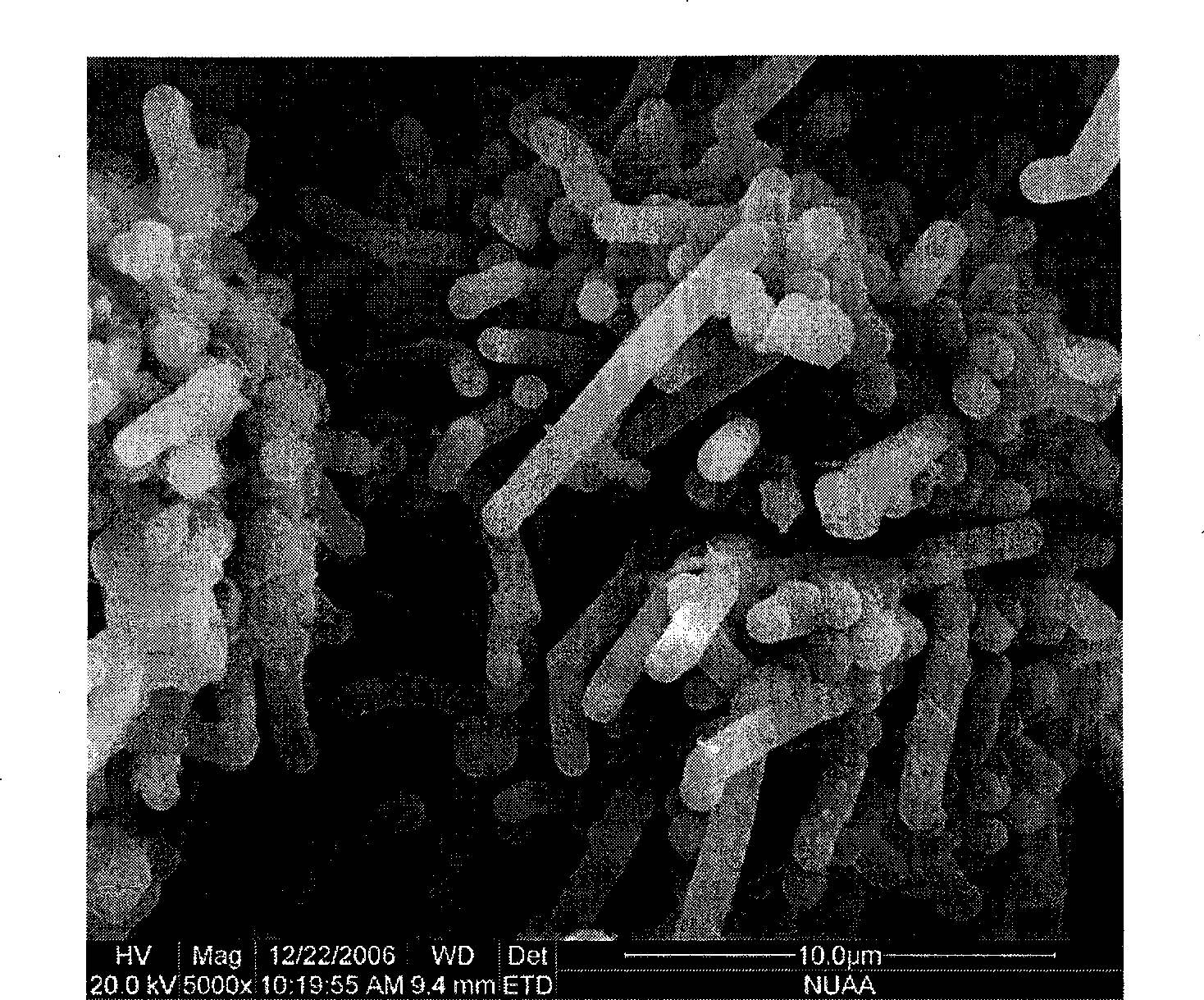

[0034] Embodiment 2: Preparation of Nano-SiC Whiskers 2

[0035] The nano-SiC whiskers prepared in this embodiment adopt PVA (polyvinyl alcohol) binder.

[0036] Steps:

[0037] In the first step, PVA (polyvinyl alcohol) is dissolved in hot water to make an 8% PVA solution, which is kept in a high-temperature furnace (80° C.) for 1 day.

[0038] In the second step, take 30g of nano-SiC powder into a beaker, take 5ml of 8% PVA (polyvinyl alcohol) solution into the beaker, stir evenly, put it in a dryer to dry, take it out and stir evenly, and add it to the mold cavity.

[0039]The third step is to adopt the principle of cold isostatic pressing to apply pressure P (10MPa) to the mold and keep the pressure for 4 minutes, and then the mold can be demoulded to obtain a cylindrical block nano-SiC briquette with a diameter of 40mm and a thickness of 3mm.

[0040] The fourth step is to use a CO2 laser, set the diameter of the laser spot to 0.3mm, the scanning speed to 0.2m / min, and...

Embodiment 3

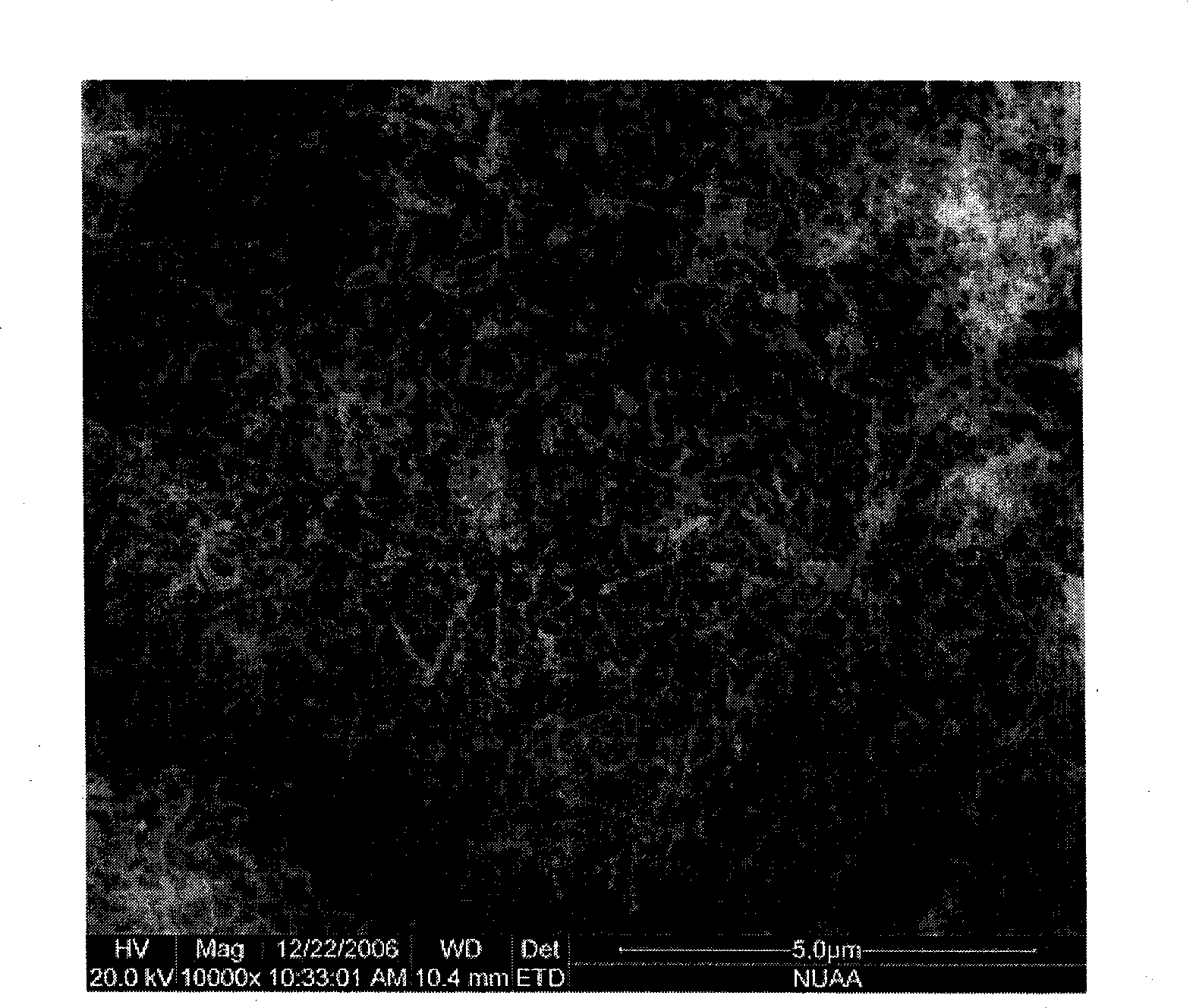

[0041] Example 3: Preparation of Nano-SiC Whiskers 3

[0042] The nano-SiC whiskers prepared in this example use CMC (sodium carboxymethylcellulose) binder.

[0043] In the first step, CMC (sodium carboxymethylcellulose) is dissolved in hot water to make a 5% CMC solution.

[0044] In the second step, put 30g of nano-SiC powder into a beaker, pour 5ml of 5% CMC (sodium carboxymethyl cellulose) solution into the beaker, stir evenly, and put it into a dryer for drying (to pinch the particles by hand) There is no damp feeling), take it out and stir evenly, and add it to the mold cavity.

[0045] The third step is to adopt the principle of cold isostatic pressing to apply pressure P (8 MPa) to the mold, and keep the pressure for 1 minute, and then the mold can be demoulded to obtain a cylindrical block nano-SiC briquette with a diameter of 40 mm and a thickness of 3 mm.

[0046] The fourth step is to use a CO2 laser, set the diameter of the laser spot to 0.3mm, the scanning spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com