Method for producing butylenes-1 with hydroisomerization of butylenes-2

A technology of hydroisomerization and butene, which is applied in the field of butene-2 hydroisomerization to butene-1, can solve the problems of inconvenient processing and utilization, pollution of products, troubles, etc., and achieves the improvement of isomerization activity and good Pore size distribution, effect of reducing internal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

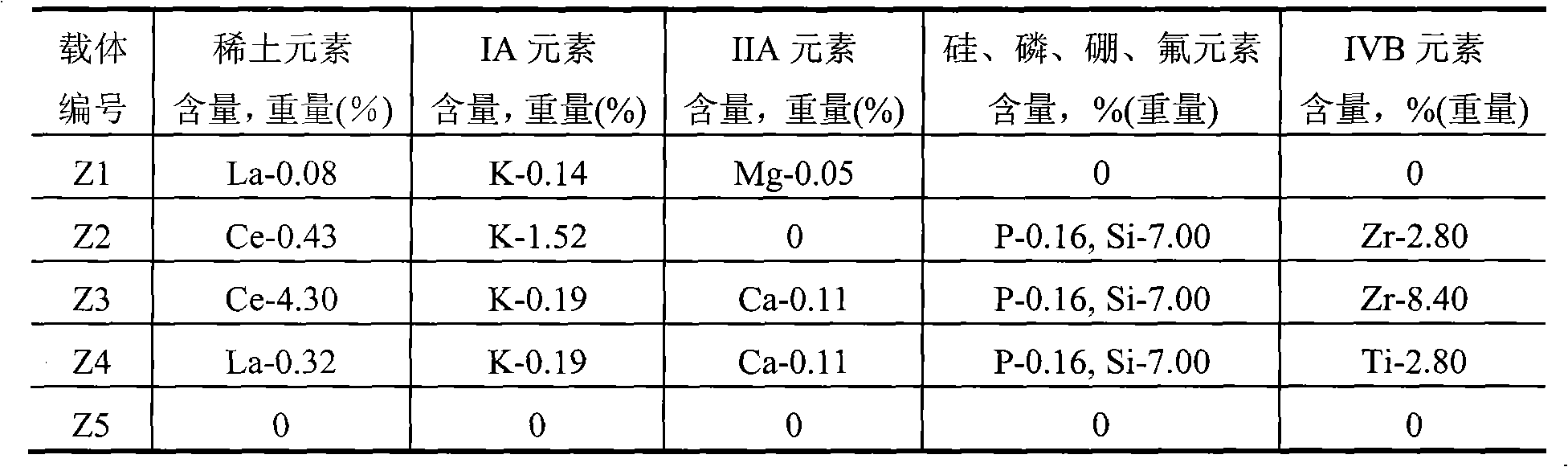

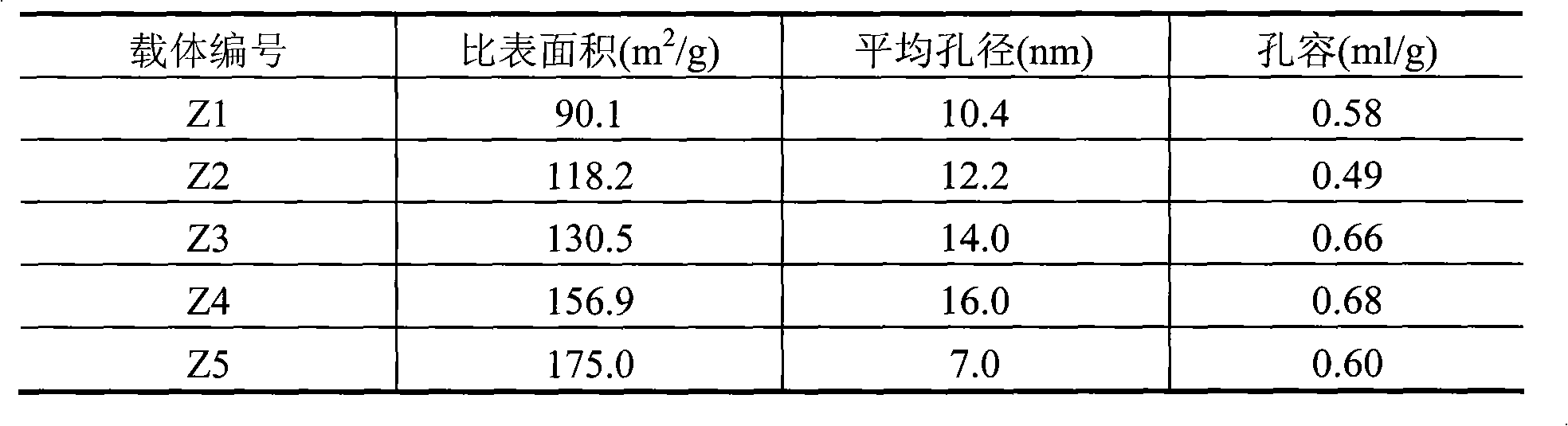

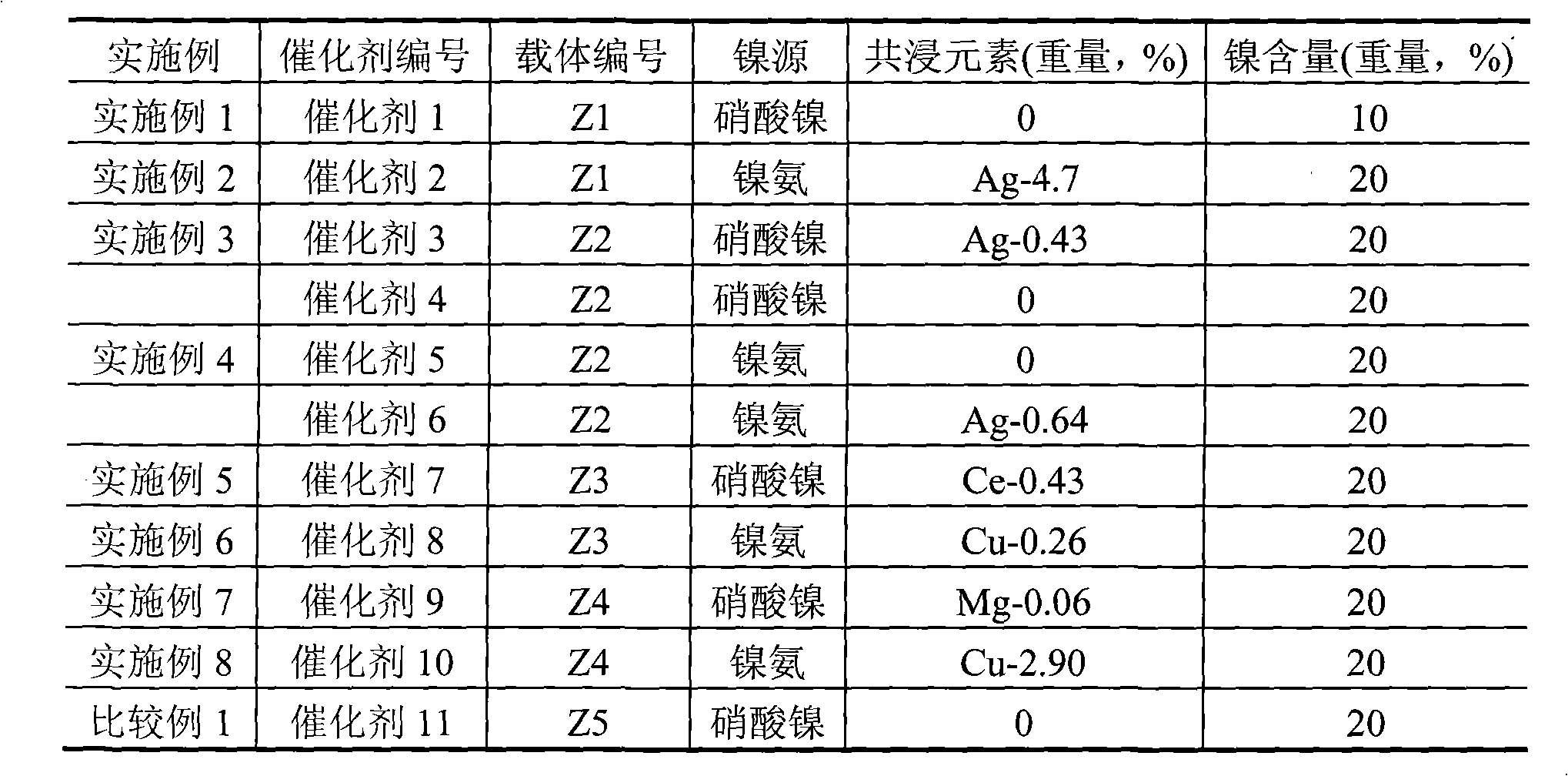

[0015] Take by weighing 300 grams of pseudo-boehmite, 150 grams of δ-alumina, 9 grams of scallop powder, mix, then add 25 grams of polyvinyl alcohol-containing solution (mass concentration is 5%), and concentration is 4.0 grams of 68% nitric acid , 1.5 grams of potassium nitrate, 2 grams of magnesium nitrate, 1.0 grams of lanthanum nitrate, 360 ml of aqueous solution, extruded into a clover-shaped carrier with a diameter of 2.5 mm, dried at 120°C for 4 hours and then roasted at 750°C for 4 hours to obtain carrier Z1 , the composition of the carrier is shown in Table 1, and the surface properties of the carrier are shown in Table 2. The carrier was impregnated in the same amount of nickel nitrate impregnation solution with a metal nickel content of 14%, dried at 60°C for 8 hours, and calcined at 450°C for 4 hours to obtain Ni-based catalyst 1, so that the final Ni content was 10.0% of the weight of the carrier alumina. %. The catalyst composition is shown in Table 3, and the c...

Embodiment 2

[0017] Carrier Z1 was used, and the preparation method of the carrier was the same as in Example 1, and the composition of the carrier was shown in Table 1. With the same operating steps and conditions of Example 1, just change the nickel solution to be a nickel-ammonia complex solution (nickel carbonate: ammonium carbonate: ammoniacal liquor=1.0: 1.0: 1.0) with a metal nickel content of 12.0%, and add nitric acid in the dipping solution 30.0 grams of silver was used to prepare Ni-based catalyst 2, so that the final Ni content was 20.0% of the carrier weight. The catalyst composition is shown in Table 3, and the content of each component is based on the weight of the carrier.

Embodiment 3

[0019]Take by weighing 300 grams of pseudo-boehmite, 45 grams of diatomaceous earth, and 9 grams of asparagus powder, mix, then add 25 grams of polyvinyl alcohol solution (mass concentration is 5%), and the concentration is 4.0 grams of 68% nitric acid, 1.8 grams of phosphoric acid with a concentration of 85%, 12.0 grams of potassium nitrate, 40.0 grams of zirconium nitrate, 3.0 grams of cerium nitrate, 360 milliliters of aqueous solution, extruded into a clover carrier with a diameter of 2.5 mm, wet strips dried at 50 ° C for 24 hours and then dried at 750 ° C Calcined for 4 hours, the carrier Z2 was obtained. The composition of the carrier is shown in Table 1, and the surface properties of the carrier are shown in Table 2. Mix 3.0 grams of silver nitrate with 50 grams of nickel nitrate solution with a metal nickel content of 14% to prepare an impregnation solution. The carrier and the impregnating solution were impregnated in equal amounts to obtain Ni-based catalyst 3.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com