Preparation method of disk hexagonal boron nitride polycrystalline fine powder

A hexagonal boron nitride and sheet-like technology is applied in the field of preparation of wafer-like hexagonal boron nitride polycrystalline micropowder, which can solve the problems of complex process, high reaction temperature and high resource consumption, and achieves simple process and lower reaction temperature. , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

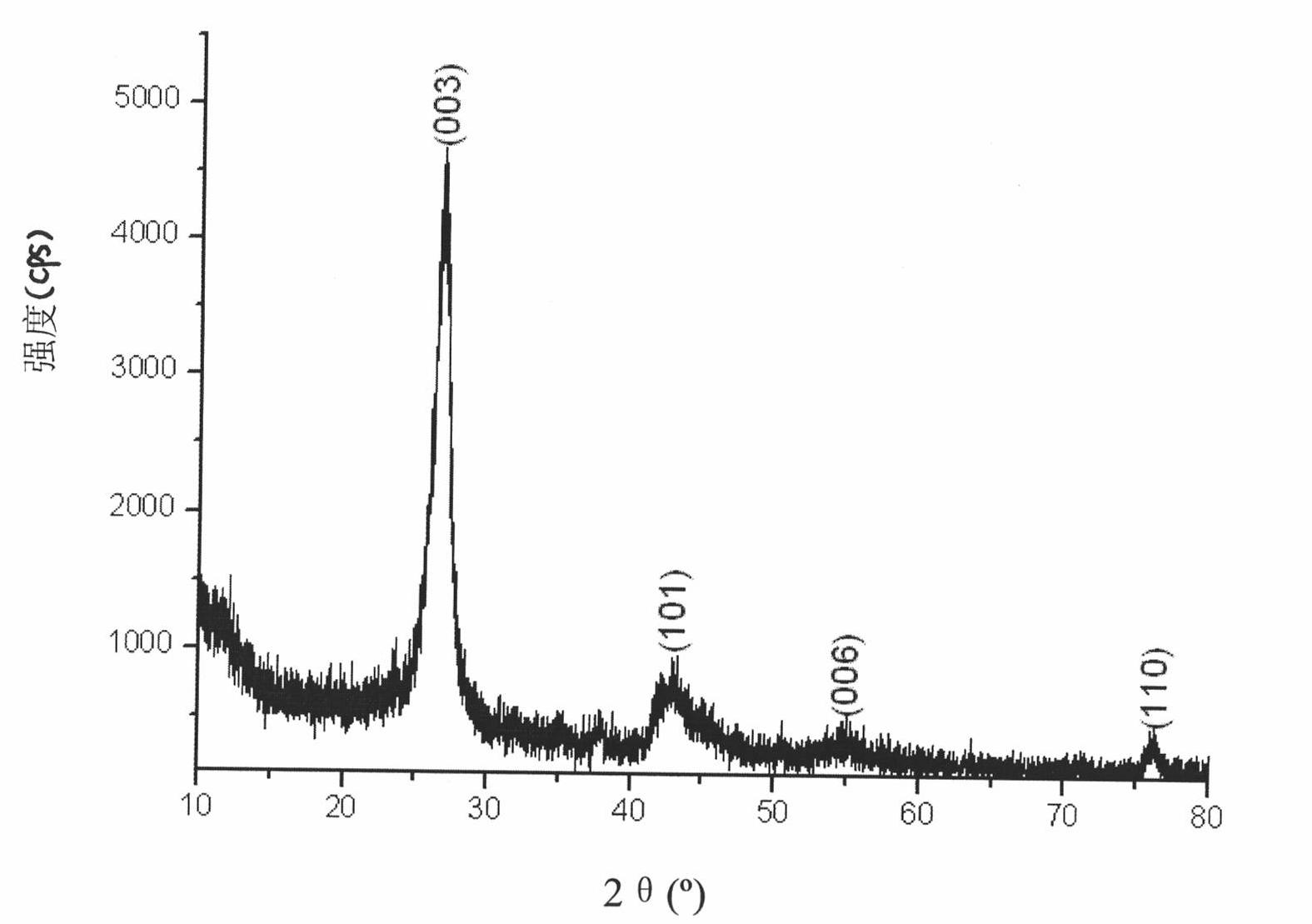

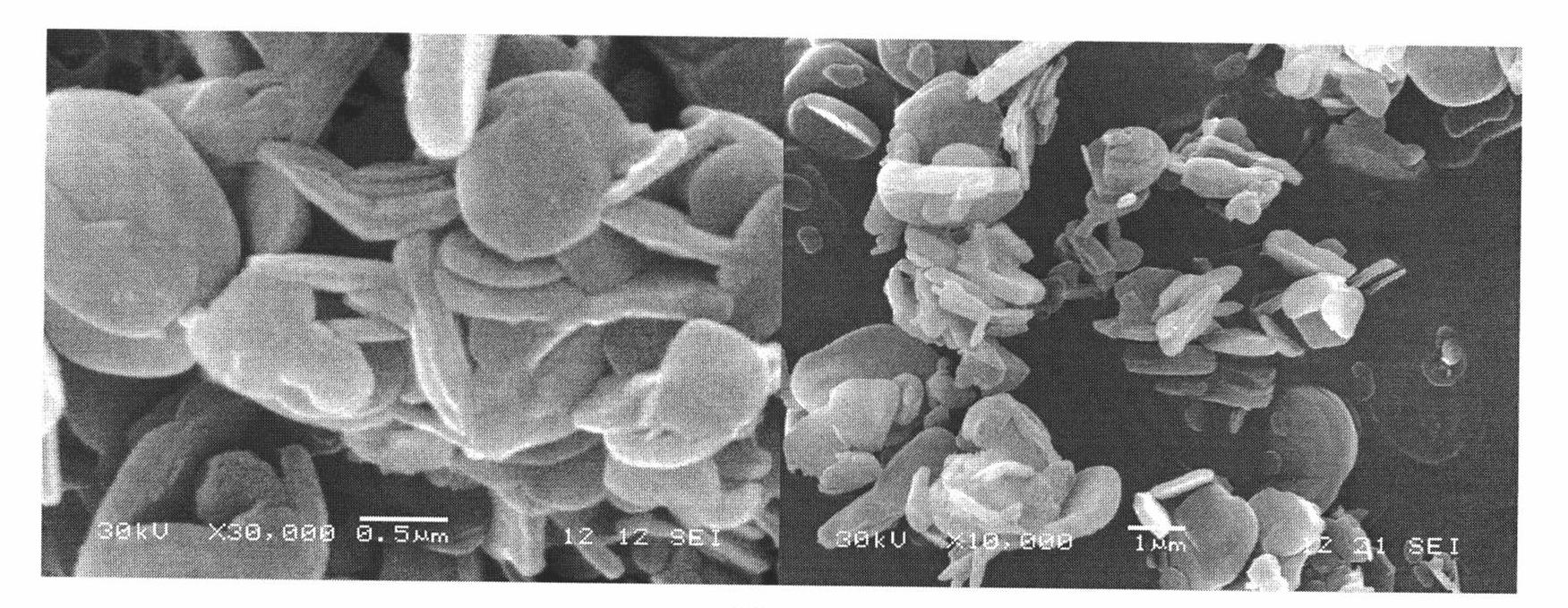

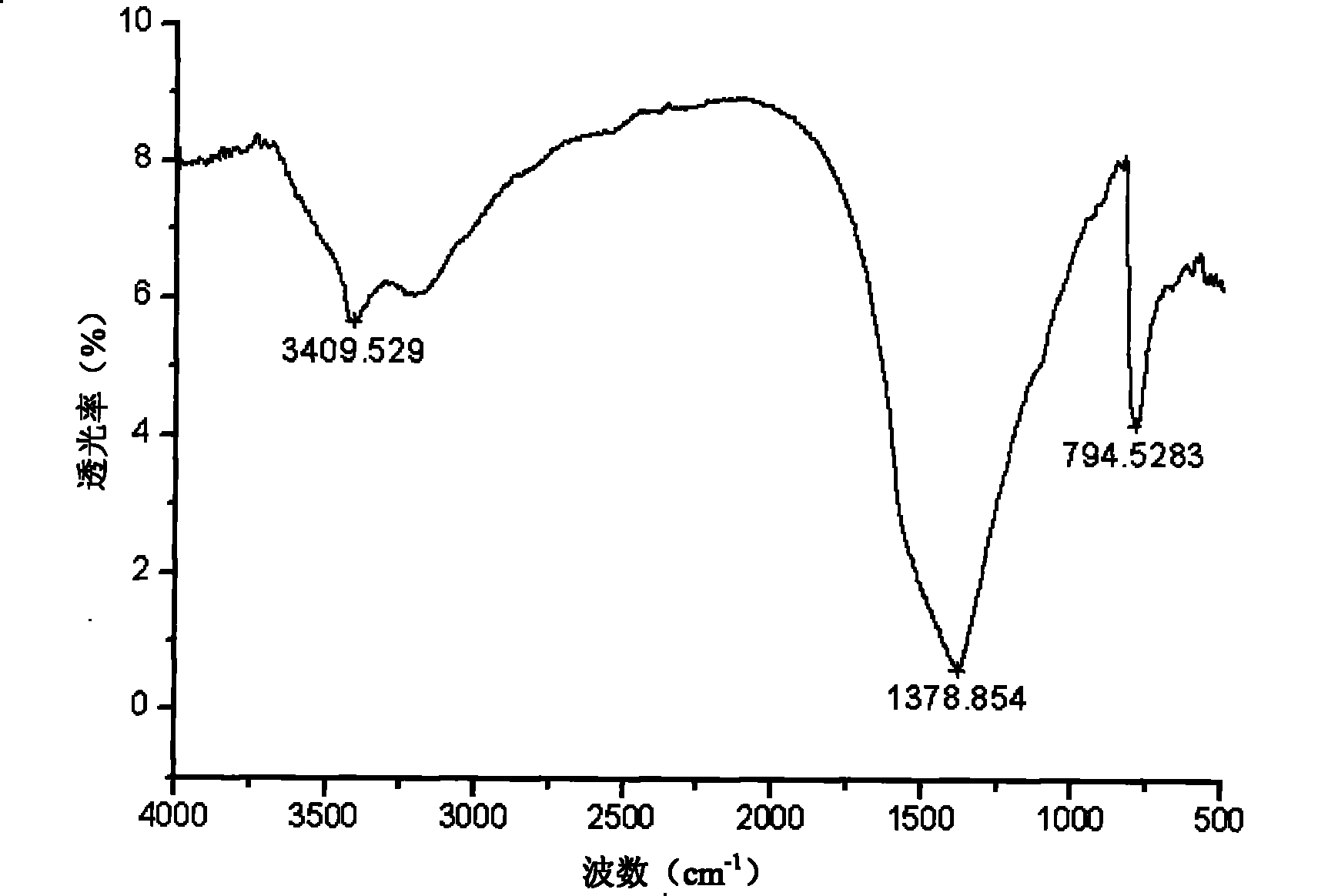

[0023] Take 5.64 grams of B 2 o 3 , 19.24 g NH 4 Cl, 3.92 grams of magnesium powder and 1.61 grams of Fe 2 o 3 (element molar ratio B: N: Mg: M = 1: 2.24: 1.02: 0.13, M = Fe) After fully mixing, add the stainless steel reaction tank, put the reaction tank into a nitrogen-protected heating furnace, and keep it at 750 ° C for 15 Minutes, cool down naturally. Open the tank and process the collected product, soak it in 0.5M dilute hydrochloric acid and stir for 30 minutes to dissolve impurities such as catalyst, then filter with suction and wash with water to remove water-soluble impurities such as magnesium chloride, and dry the filter cake at 80°C for 8 hours to obtain 3.89 gram off-white powder, the yield is 97.25%. After XRD, SEM and FTIR analysis, it is proved that the product is disc-shaped h-BN, the size and shape of the crystal grains are uniform, the particle diameter is 0.5-1.4 μm, the average diameter is about 0.9 μm, the thickness is 80-150 nm, and the average thi...

Embodiment 2

[0032] Take 2.81 grams of B 2 o 3 , 18.62 g NH 4 Cl, 2.94 g magnesium powder and 1.71 g Co 2 o 3 (Element molar ratio B: N: Mg: M=1: 4.29: 1.51: 0.26, M=Co) After fully mixing, add the stainless steel reaction tank, put the reaction tank into a heating furnace protected by nitrogen, and keep it warm at 800 ° C for 18 Minutes, cool down naturally. Open the tank and process the collected product, soak it in 2M dilute hydrochloric acid, and stir for 30 minutes to dissolve impurities such as catalyst, then filter with suction and wash with water to remove water-soluble impurities such as magnesium chloride, dry the filter cake at 80°C for 12 hours, and finally obtain 1.93 grams Off-white powder with a yield of 96.5%. After XRD, SEM and FTIR analysis, it is proved that the product is disc-shaped h-BN, the size and shape of the crystal grains are uniform, the particle diameter is 0.6-1.3μm, the average diameter is about 0.9μm, the thickness is 70-130nm, the average thickness A...

Embodiment 3

[0034] Take 4.94 g H 3 BO 3 , 12.93 g NH 4 NO 3 , 3.04 grams of magnesium powder and 3.82 grams of NiCl 2 (Element molar ratio B: N: Mg: M=1: 3.94: 1.54: 0.36, M=Ni) After fully mixing, add the stainless steel reaction tank, put the reaction tank into a heating furnace protected by nitrogen, and keep it at 800 ° C for 16 Minutes, cool down naturally. Open the tank and process the collected product, soak it in 5M dilute nitric acid, and stir for 30 minutes to dissolve impurities such as catalyst, then filter with suction and wash with water to remove water-soluble impurities such as magnesium chloride, dry the filter cake at 80°C for 8 hours, and finally obtain 1.87 grams Off-white powder with a yield of 93.51%. After XRD, SEM and FTIR analysis, it is proved that the product is disc-shaped h-BN, the grain size and shape are uniform, the particle diameter is 0.5-1.3μm, the average diameter is about 0.85μm, the thickness is 60-120nm, and the average thickness About 90nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com