Production method of amino acid bio-organic fertilization fertilizer

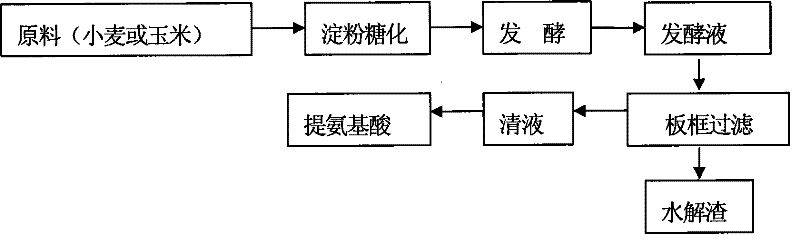

A production method and fertilization technology applied in the direction of organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve problems such as time-consuming, increased soil diseases, and heavy air pollution, so as to increase crop yield, improve soil structure, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Sampling: The hydrolyzed slag was taken from Henan Lianhua Amino Acid Co., Ltd.

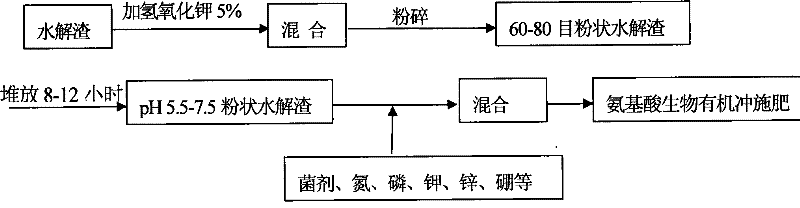

[0029] 2. pH adjustment: Add 5% potassium hydroxide to the hydrolyzed slag, mix it, grind it to 80 mesh with a chain crusher, and stack it for 8-12 hours to allow it to fully react. The basic properties of the hydrolyzed slag after treatment are shown in Table 1.

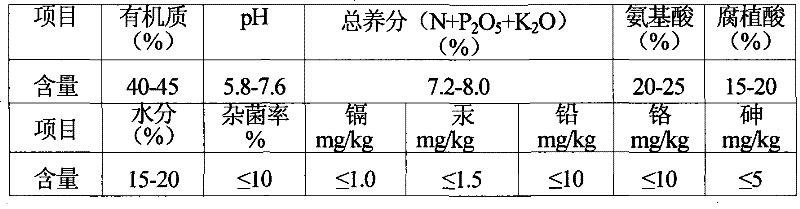

[0030] Table 1 Basic properties of hydrolyzed slag (powder) after treatment

[0031]

[0032] 3. Turn over: Use a forklift or manually turn over the pile, let the temperature of the reacted material cool down to normal temperature, and make the pH reach 5.5-7.5;

[0033]4. Preparation of compound microbial bacterial agent: Bacillus subtilis and Bacillus mucilaginosus are produced by separate fermentation using fermentation equipment, and the fermented bacterial liquid is respectively pressed with 80-mesh rice husk powder: rice husk Powder = 1:3 ratio for adsorption, mix the two adsorbed single bacterial agent...

Embodiment 2

[0044] Add 6% potassium hydroxide to the hydrolyzed slag and mix it, pulverize it to 100 mesh with a chain crusher and stack it for 8-12 hours to allow it to fully react;

[0045] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 1:2.5, and they are crushed to 100 mesh after mixing. The fineness of rice husk powder is 100 mesh, and the adsorption ratio of bacterial agent to rice husk powder is 1:5.

[0046] The adding ratio of bacterial agent is 6%, and the adding ratio of hydrolyzed slag is 64%, and other is with embodiment 1.

Embodiment 3

[0048] Add 6% potassium hydroxide to the hydrolyzed slag, mix it with a chain crusher to 120 mesh, and stack it for 8-12 hours to allow it to fully react;

[0049] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 1:1.5, and they are crushed to 120 mesh after mixing. The fineness of rice husk powder is 120 mesh, and the adsorption ratio of bacterial agent to rice husk powder is 1:4.

[0050] The addition ratio of bacterial agent is 8%, and the addition ratio of hydrolysis slag is 63%, and the addition ratio of urea is 14%, and other is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com