Method for realizing controlled doping of nano silicon quantum dots

A nano-silicon quantum dot and silane technology, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of low film crystallization rate and low activation rate of dopant atoms, and achieve broad application prospects and short processing time , the effect of improving the photoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

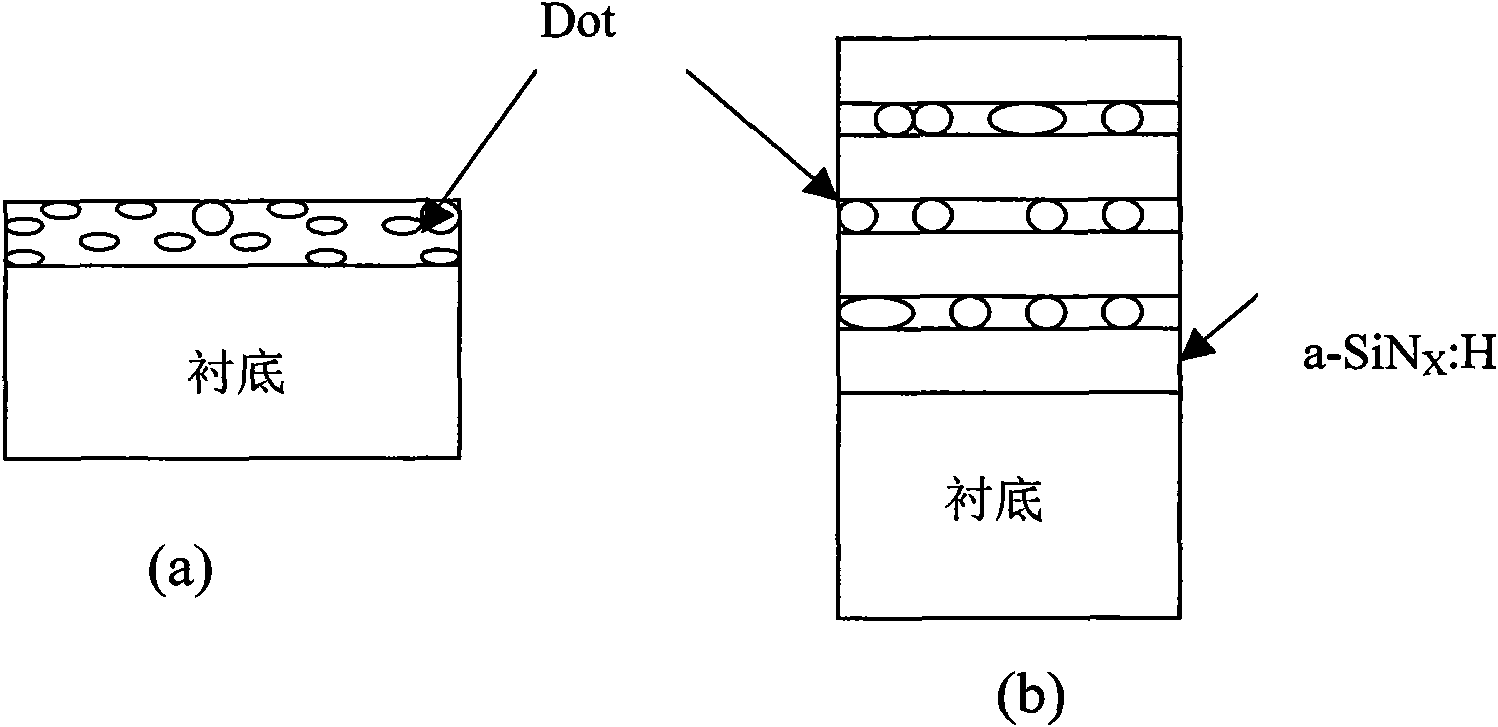

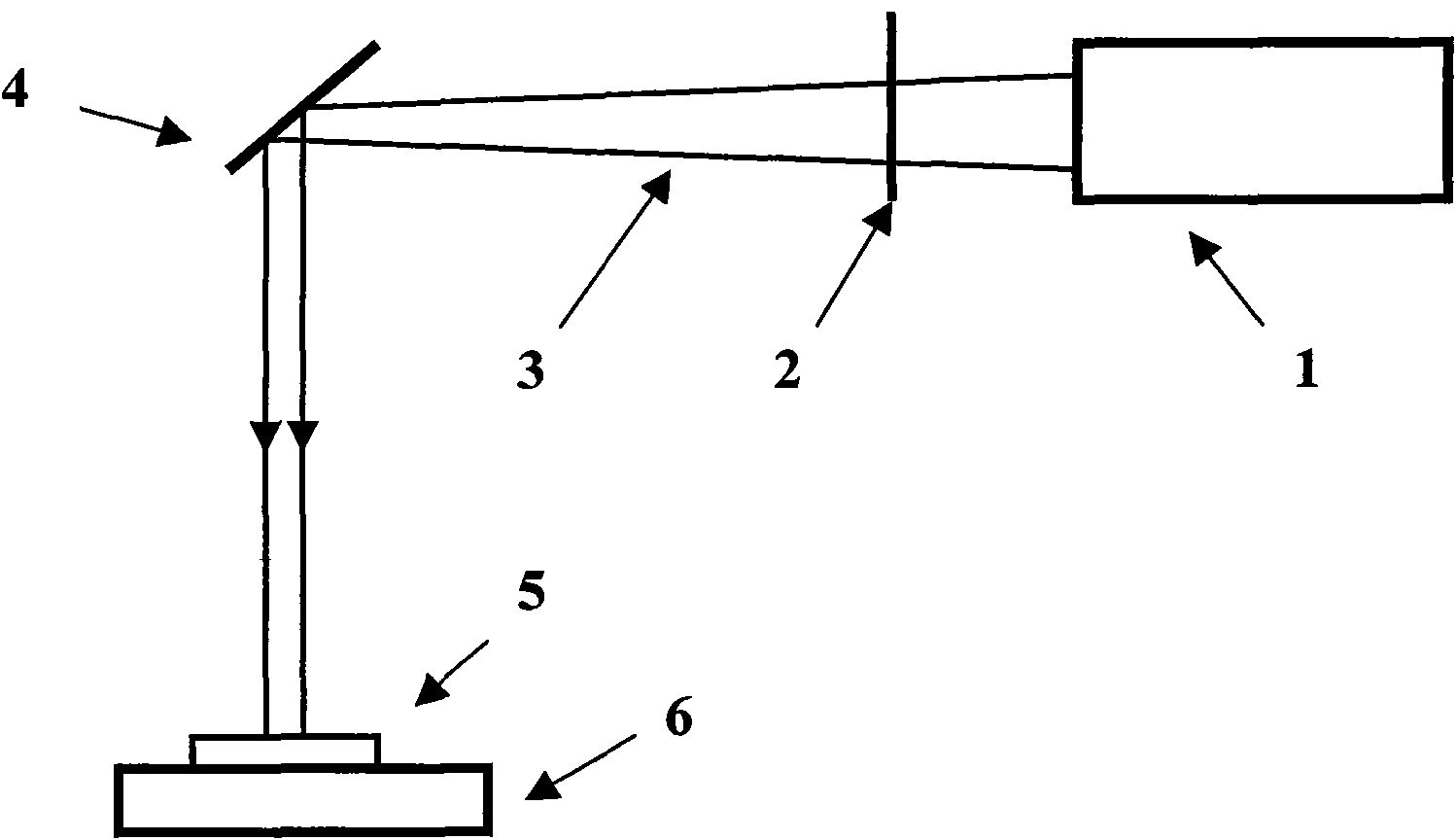

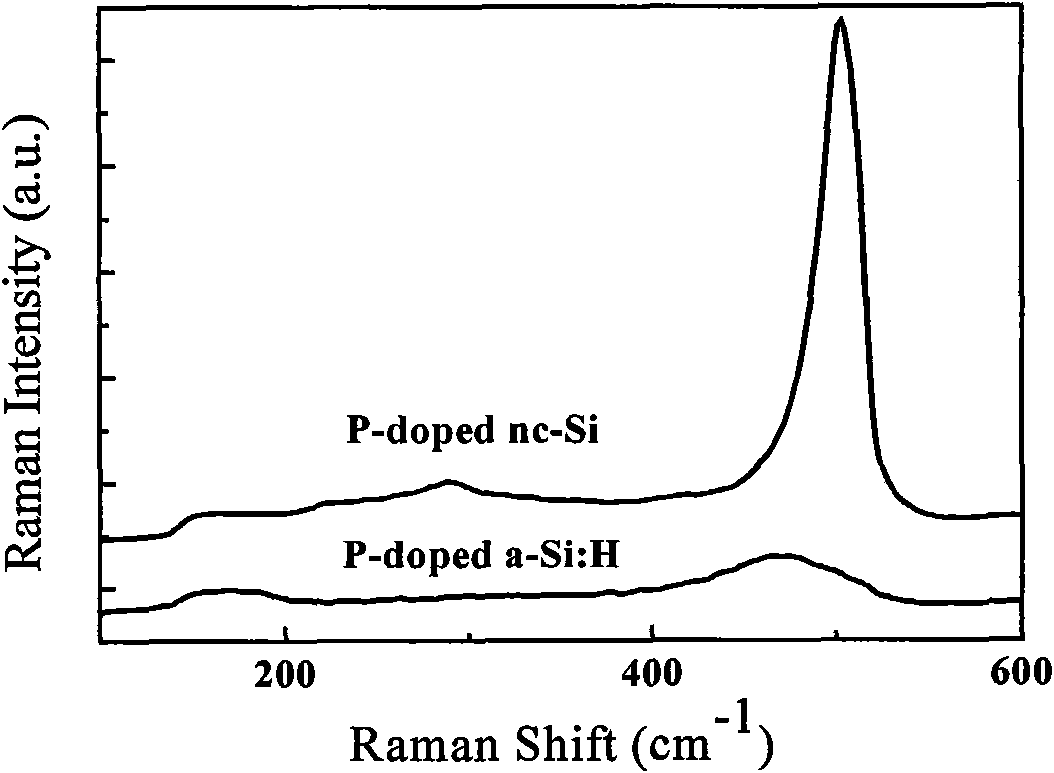

[0027] The method for realizing the controllable doping of nano-silicon quantum dots in this embodiment combines the doped amorphous silicon single-layer film with laser crystallization technology, and uses an appropriate energy laser to induce the crystallization of the doped amorphous silicon single-layer film to obtain doped Concentration-controllable nano-silicon quantum dot monolayer film. Specific steps are as follows

[0028] 1. Preparation of basic materials:

[0029] (1) Preparation of ultra-thin doped amorphous silicon monolayer film

[0030] A flat capacitive RF plasma-enhanced chemical vapor deposition (PECVD) device was used as the growth system, and the reaction gas source was silane (SiH) with a volume mixing ratio of 5:1-10. 4 ) and phosphine (PH 3 ) (or use B 2 h 6 Prepare B-doped amorphous silicon film) mixed gas, select a lower ratio for light doping, and choose a higher ratio for heavy doping. The substrate is made of single crystal silicon wafer, qua...

Embodiment 2

[0039] The method for realizing the controllable doping of nano-silicon quantum dots in this embodiment combines the doped amorphous silicon multilayer film with laser crystallization technology, and uses appropriate energy laser to induce the crystallization of the doped amorphous silicon layer in the multilayer film to obtain Nano silicon quantum dot multilayer film with controllable doping concentration. Specific steps are as follows

[0040] 1. Preparation of basic materials:

[0041] (1) Preparation of confinement layer

[0042] The substrate material is placed on the grounded metal plate in the reaction chamber of the radio frequency plasma enhanced chemical vapor deposition equipment, and the gas source is silane (SiH 4 ) and ammonia (NH 3 ) mixed gas with a mixing ratio of 5:1-10, start the RF switch, deposit a 10-100nm thick hydrogenated amorphous silicon nitride (a-SiNx:H) film on the substrate material, and turn off the RF switch after completion ;

[0043] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com