Hydrogen-dissolved aqueous solution and method for prolonging the life duration of hydrogen dissolved in the aqueous solution

An aqueous solution and dissolved hydrogen technology, applied in water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve problems such as loss of product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In this example, a compound (cell extract) having a reducing aldehyde group (CHO group) or hydroxyl group (OH group) was used. That is, when such a cell extract is added, the lifetime of dissolved hydrogen becomes longer.

[0065] The dissolved hydrogen concentration was evaluated by oxidation-reduction potential (ORP). If the dissolved hydrogen concentration increases, the ORP becomes a more negative value. Therefore, by investigating the time-dependent change of ORP, it is possible to evaluate the life extension effect of dissolved hydrogen.

[0066] As cell extracts, monosaccharides, disaccharides, oligosaccharides, polysaccharides, amino sugars, sugar alcohols, lactones, and polyphenols were used. More specifically, as shown in Table 1, D-(+)-glucose, sucrose, oligosaccharides, starch, carboxymethylcellulose, chondroitin sulfate, glycerin, sorbitol, vitamin C, and gallic acid were used.

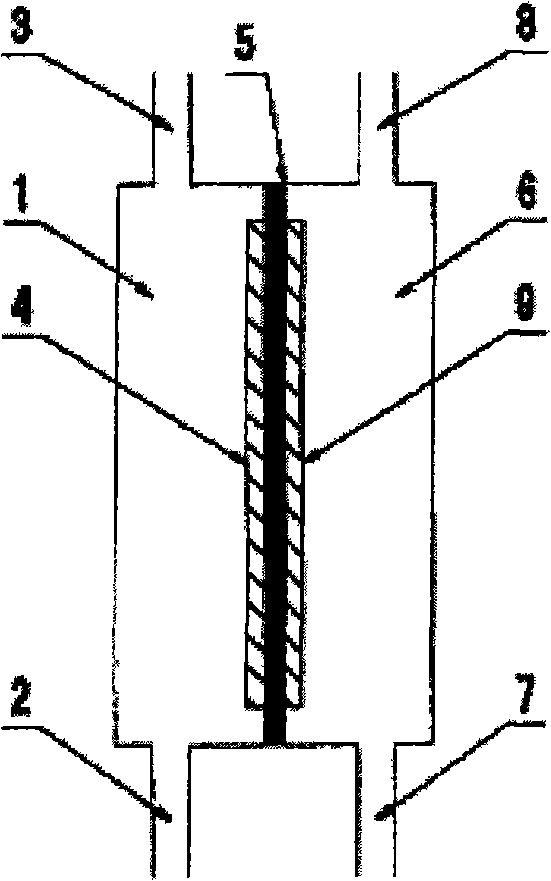

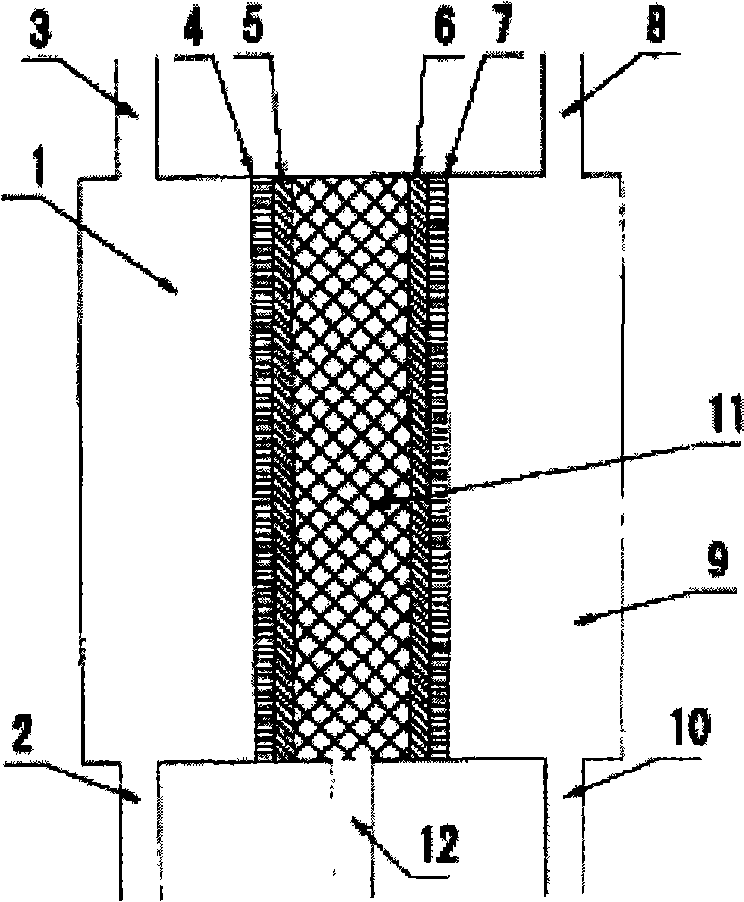

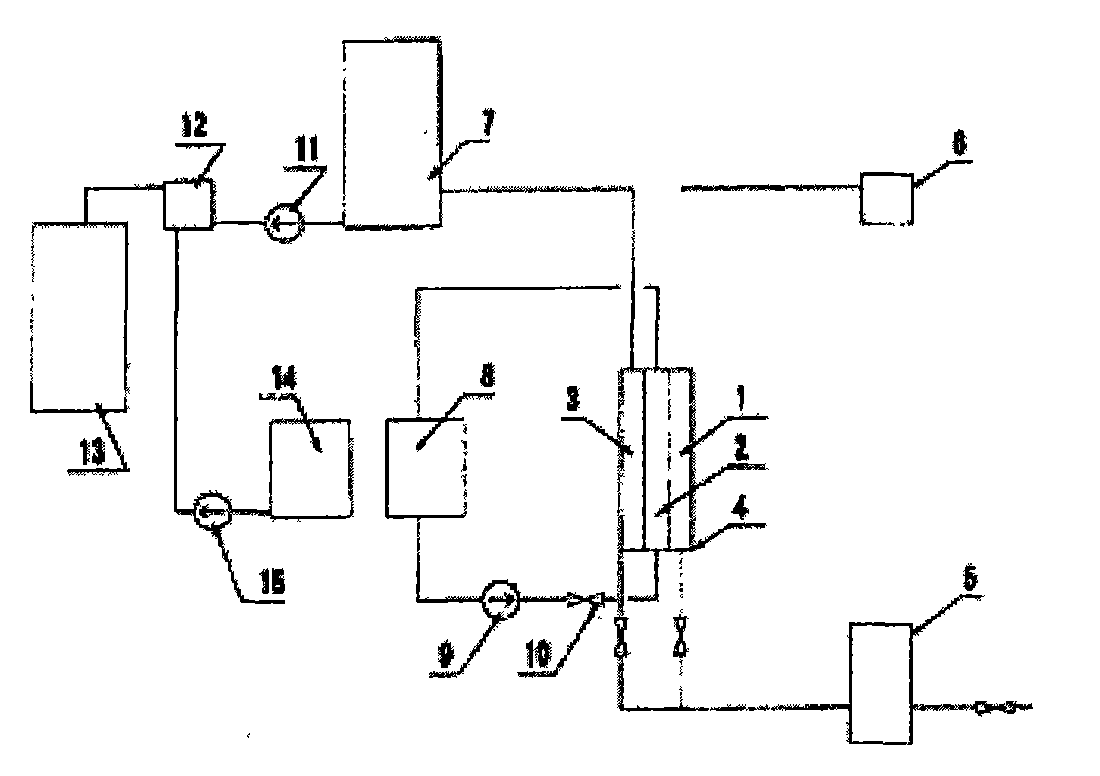

[0067] Used in hydrogen supply figure 2 The three-compartment electrolyze...

Embodiment 2

[0085] In this example, vitamin B2 having a flavin structure involved in an electron transport system or a redox reaction was also used as an additive. That is, in each case of Example 1, 0.1 g of vitamin B2 was added. The temporal change of ORP at this time is shown in Table-2.

[0086] Table 2

[0087] cell extract ORP(mV)

[0088] Immediately after addition 2 hours after 4 hours after 24 hours

[0089] Not added -422 273 367 422

[0090] Glucose (monosaccharides) -472 -499 -502 -449

[0091] Sucrose (disaccharides) -473 -500 -494 -454

[0092] Oligosaccharides (oligosaccharides) -446 -477 -460 -350

[0093] CMC (polysaccharide) -474 -554 -544 165

[0094] Starch (polysaccharide) -470 -485 -475 355

[0095] Glycerin (sugar alcohol) -436 -431 -463 200

[0096] Sorbitol (sugar alcohol) -447 -480 -475 -447

[0097] Gallic acid (polyphenols) -399 -376 -362 378

[0098] Tannic acid (polyphenol) -460 -451 -444 382

[0099] From Table-2, it is clear t...

Embodiment 3

[0101] In this example, the effect of promoting life extension of dissolved hydrogen by vitamin B3 (nicotinamide) involved in oxidation-reduction reaction in a living body was investigated. That is, in each case of Example 1, 0.5 g of vitamin B3 was added. The temporal change of ORP at this time is shown in Table-3.

[0102] table 3

[0103] cell extract ORP(mV)

[0104] Immediately after addition 2 hours after 4 hours after 24 hours

[0105] Not added -422 273 367 422

[0106] Glucose (monosaccharide) -515 -541 -540 -470

[0107] Sucrose (disaccharides) -512 -500 -505 -310

[0108] Oligosaccharides (oligosaccharides) -502 -506 -490 -130

[0109] CMC (polysaccharide) -584 -549 -553 -52

[0110] Starch (polysaccharide) -515 -485 -511 28

[0111] Chondroitin Sulfate (Amino Sugar)- -570 -562 -80

[0112]Glycerin (sugar alcohol) -527 -531 -523 -127

[0113] Sorbitol (sugar alcohol) -490 -500 -501 -129

[0114] Gallic acid (polyphenol) -398 -407 -390 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com