Method for preparing nano-doped tin oxide sol

A tin oxide sol, nanotechnology, applied to tin oxide, conductive layers on insulating carriers, electrical components, etc., can solve problems such as toxicity and use, and achieve the effects of high degree of crystallization, good stability, and environmental protection in the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Fluorine-doped SnO 2 Solution preparation: 0.6mol / L of Sn(NO 3 ) 4 Add NaOH solution to 125ml of the solution under stirring until the pH is 7. After standing and aging, the product is washed to obtain a precipitate, and then deionized water is added to the obtained precipitate, and then oxalic acid is added dropwise at a low temperature to degumming, and the temperature is gradually raised and refluxed for 3 hours. The product is added with 0.0075mol of NH 4 F, the last 24h under water heating at 140°C. Product washing and ultrasonic dispersion to obtain stable fluorine-doped SnO 2 Sol. The amount of oxalic acid added is Sn(NO 3 ) 4 60% of the dosage.

Embodiment 2

[0022] Example 2: Antimony-doped SnO 2 Solution preparation: 0.5mol / L SnCl 4 Add 0.002mol SbCl to 125mL of the solution 3, adding NH with stirring 3 ·H 2 O, until the pH is 8, after static aging, wash the product to obtain a precipitate, then add deionized water to the obtained precipitate, then drop hydrogen peroxide gel at low temperature, gradually raise the temperature, reflux for 4 hours, and finally heat at 160°C for 48 hours. Product washing and ultrasonic dispersion to obtain stable antimony-doped SnO 2 Sol. The amount of hydrogen peroxide added is SnCl 4 120% of the amount used.

Embodiment 3

[0023] Example 3: SnO doped with antimony and fluorine 2 Solution preparation: 0.4mol / L of Sn(SO 4 ) 2 Add 0.001molSbCl to 125mL of the solution 3 , add NaOH under stirring until the pH is 9, wash the product after standing and aging to obtain a precipitate, then add deionized water to the obtained precipitate, then drop hydrogen peroxide gel at low temperature, gradually heat up, reflux for 6 hours, and add 0.005 mol of NH 4 F, the last water heating at 200°C for 144h. Product washing and ultrasonic dispersion to obtain stable antimony and fluorine-doped SnO 2 Sol. The amount of hydrogen peroxide added is Sn(SO 4 ) 2 140% of usage.

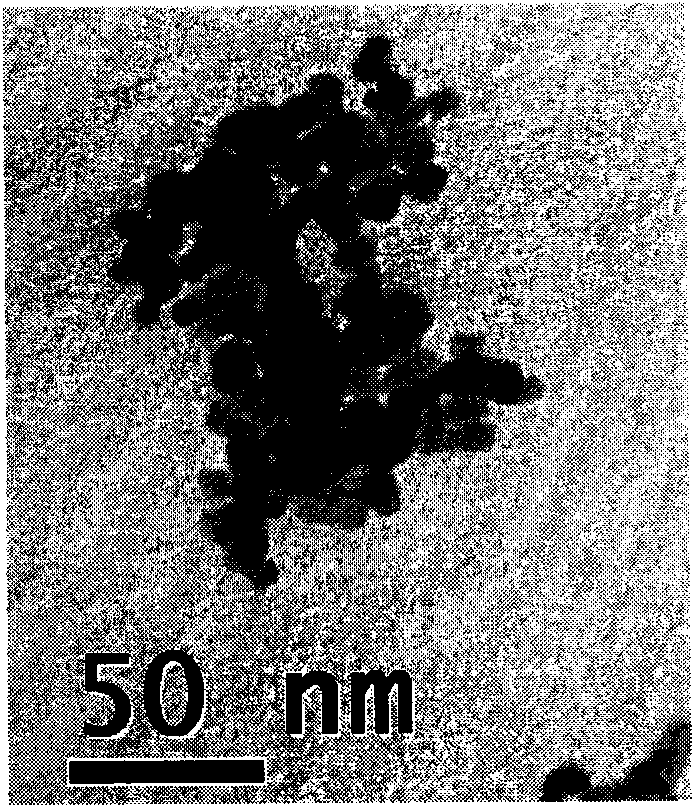

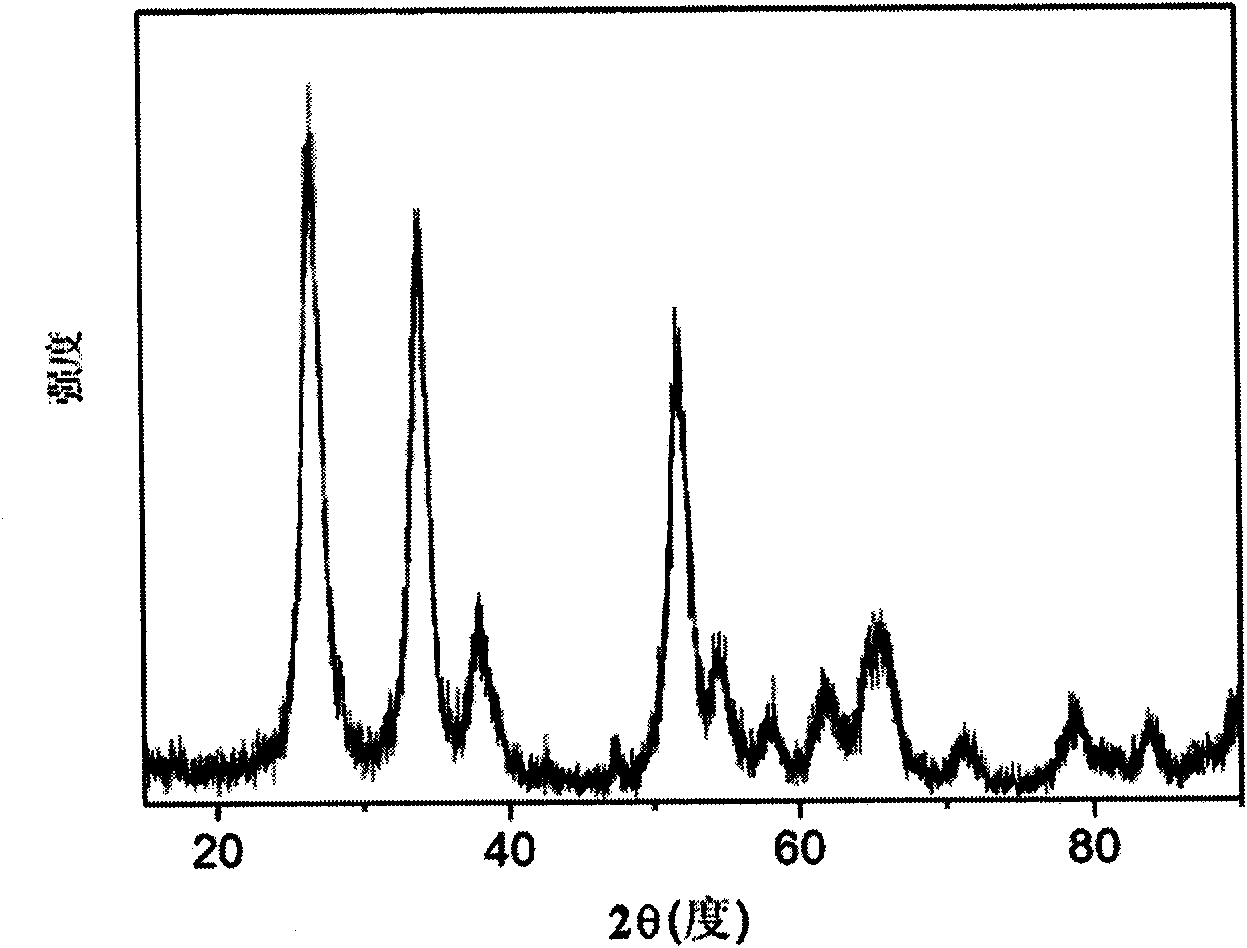

[0024] The fluorine-doped SnO in this embodiment 1 2 The detection result of solution product through transmission electron microscope (TEM) and X-ray diffractometer (XRD) is referring to in the accompanying drawing figure 1 and figure 2 .

[0025] figure 1 shows that nanofluorine-doped SnO 2 It can be seen that the particle size d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com