Method for growing AIN or AlGaN film

A thin film and epitaxial growth technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of complex growth process and harsh conditions of buffer layer, so as to improve luminescence characteristics, improve crystal quality and Surface flatness, effect of improving surface topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare AlN thin films according to the following steps:

[0023] 1) Raise the temperature of the reaction chamber to 1060°C, and bake the sapphire (0001) substrate in a hydrogen atmosphere for 15 minutes;

[0024] 2) The temperature was raised to 1200° C., the flow rate of TMIn was set to 180 sccm, the pressure was 50 torr, the V / III was 400, and a 600 nm AlN film was grown on a sapphire substrate at a growth rate of 400 nm per hour.

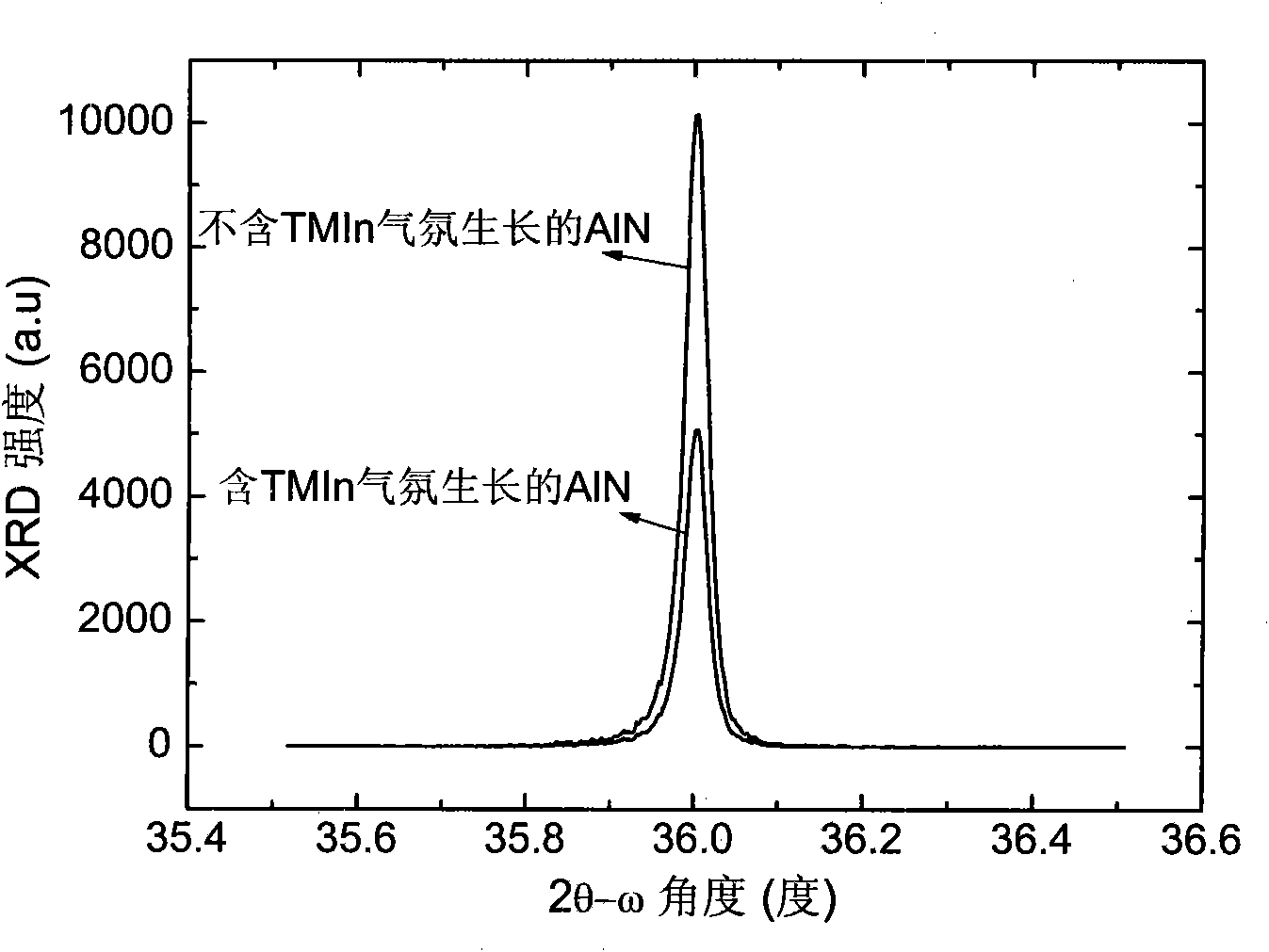

[0025] The XRD (002) plane 2θ-ω scanning results of the AlN samples grown by this special method in an atmosphere containing TMIn and the AlN film grown directly on a sapphire substrate without an atmosphere of TMIn are as follows: figure 1 shown. Depend on figure 1 It can be seen that the XRD peak position does not change significantly, indicating that TMIn only acts as an active agent during the growth of AlN, but does not participate in the formation of components. The AFM morphology comparison of AlN grown in an atmosphere contain...

Embodiment 2

[0027] Prepare AlN thin films according to the following steps:

[0028] 1) Raise the temperature of the reaction chamber to 1060°C, and bake the sapphire (001) substrate in a hydrogen atmosphere for 15 minutes;

[0029] 2) Raise the temperature to 1200°C, and grow an AlN buffer layer with a thickness of 100nm for 100 cycles on the sapphire substrate at a growth rate of 200nm per hour by pulsed atomic layer epitaxy. The growth conditions are: pressure 150torr, V / III 600, In each cycle, 5s TMAl, 3s hydrogen, 5s NH are injected sequentially 3 , 3s hydrogen;

[0030] 3) keep the temperature constant, on the basis of step 2), the flow rate of TMIn is set to 180sccm, using TMAl, TMIn and NH 3 At the same time, the method of feeding into the reaction chamber grows an AlN film at a growth rate of 400nm per hour, with a thickness of 600nm, and the specific growth conditions are: pressure 50torr, V / III 400.

[0031] The AFM of the AlN sample obtained by this special method and the A...

Embodiment 3

[0033] Prepare AlGaN thin films according to the following steps:

[0034]1) Raise the temperature of the reaction chamber to 1060°C, and bake the sapphire (0001) substrate in a hydrogen atmosphere for 15 minutes;

[0035] 2) Raise the temperature of the reaction chamber to 1200°C, and directly grow a 320nm AlN film on the sapphire substrate at a growth rate of 1.4 μm per hour. The growth conditions are: pressure 50torr, V / III 400;

[0036] 3) On the basis of step 2), keep the temperature constant and grow AlN / Al for 10 cycles x Ga 1-x N superlattice, in which the thickness of the well and the barrier in the superlattice are both 5nm, and the Al composition x is controlled at 0.8. During the growth process, the pressure is 75torr, and V / III is 600;

[0037] 4) keep the growth temperature constant, on the basis of step 3), the flow rate of TMIn is set to 240sccm, using TMAl, TMGa, TMIn and NH 3 Simultaneous access to the reaction chamber method to grow Al at a growth rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com