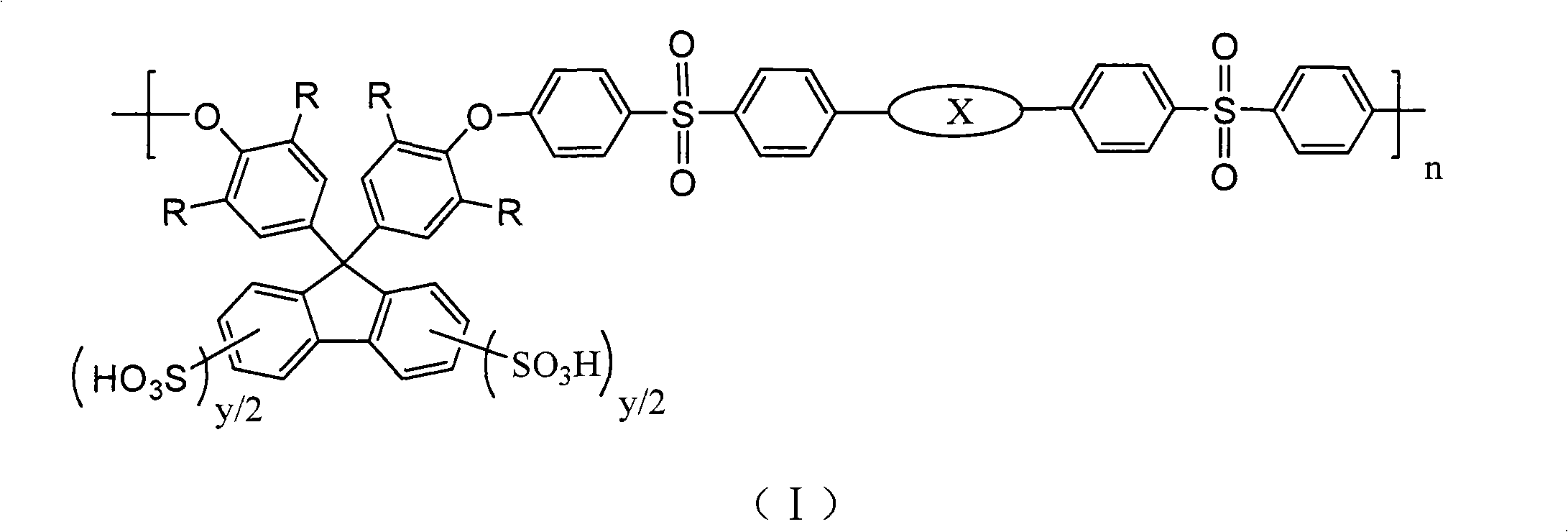

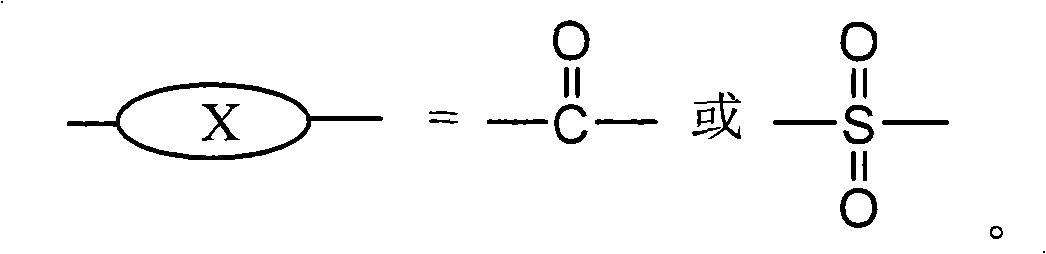

Sulfonated fluorene-containing polyether sulphone for proton exchange membrane of all-vanadium flow battery and preparation method and application thereof

An all-vanadium redox flow battery and proton exchange membrane technology, applied in fuel cell parts, battery pack parts, circuits, etc., can solve problems such as uncharacterized chemical stability, high vanadium ion permeability, and battery performance degradation. , to achieve high coulombic efficiency and energy conversion efficiency, avoid interaction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

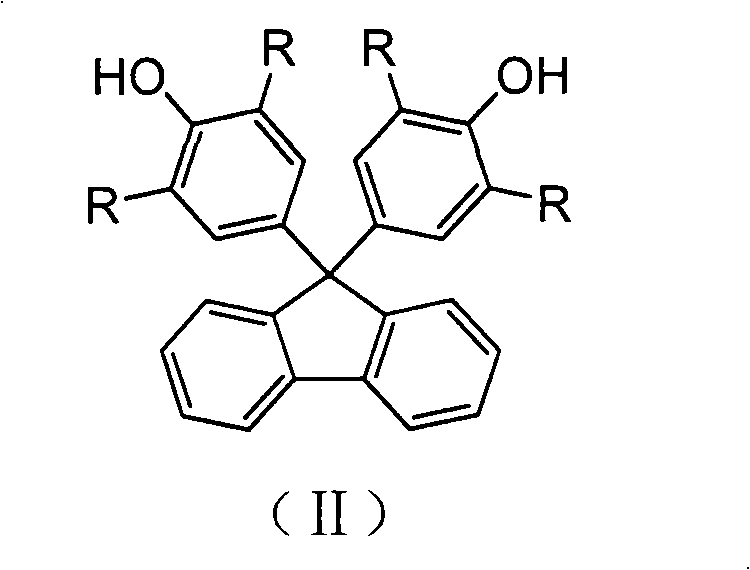

[0039] Preparation of sulfonated polyaryl ether sulfone containing fluorene:

[0040] At room temperature, add 0.5 mmol of fluorene-containing polyaryl ether sulfone 1aa into a 150 mL single-necked flask, add 50 mL of dichloromethane, and magnetically stir to dissolve it. According to the number of moles of repeating units in the fluorene-containing polyaryl ether sulfone 1aa molecule The molar ratio to the chlorosulfonic acid molecule is 1:6 (raw material ratio). Weigh 0.133mL (2mmol, 0.234g) of chlorosulfonic acid, add 10mL of dichloromethane to prepare a solution, and slowly add dropwise with a constant pressure dropping funnel After reacting for 6 hours at room temperature, a brown precipitate formed. Pour out the dichloromethane, wash the product 3 times with 10 mL of cyclohexane, add 10 mL of DMAc, stir for 1-2 hours to fully dissolve, add 20 mL of 3wt% sodium hydroxide solution, Stir for 6 hours, add 100 mL of 5 vol% hydrochloric acid solution, stir for 6 hours, transfer t...

Embodiment 2~8

[0042] The sulfonation steps of Examples 2, 3, 4, 5, 6, 7 and 8 are the same as those of Example 1, except for the ratio of raw materials or the chemical structure of polyaryl ether sulfone containing fluorene, the degree of sulfonation (y Values) are different, as shown in Table 1:

[0043] Table 1 Results of sulfonation of fluorene-containing polyaryl ether sulfones with different molecular structures

[0044] Example

Embodiment 9

[0045] Example 9 Preparation of a single component film

[0046] Take the sulfonated fluorene-containing polyaryl ether sulfone 2aa 1g prepared according to Example 1, add 20mL DMAc, heat and stir to dissolve, filter, concentrate the filtrate to 10mL, and cast on a horizontally placed glass plate in a dust-free environment Dry at 80°C to obtain a single component film 2-1.

[0047] Fenton reagent (3wt.%H 2 O 2 +2ppm FeSO 4 ) To determine its anti-oxidation stability, and measure the time for the membrane to begin to decompose flocculent sediment in a water bath shaker at 80°C.

[0048] The prepared membrane was acidified with 1M sulfuric acid at 80°C for 24 hours, and then immersed in ultrapure water for 24 hours to wash off the excess acid adsorbed in the membrane. Use an AC impedance tester to measure its room temperature conductivity.

[0049] VO 2+ Permeability to characterize the resistance to vanadium ion penetration. One side of the membrane is 1MVOSO 4 +1M H 2 SO 4 Solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com