Method for electrodepositing lead by ionic liquid system

An ionic liquid and electrodeposition technology, applied in the field of electrodeposition lead process, can solve the problems of difficult maintenance, yellowing and turbid bath liquid, complicated process, etc., and achieves good thermal stability and chemical stability, no hydrogen release, high current The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

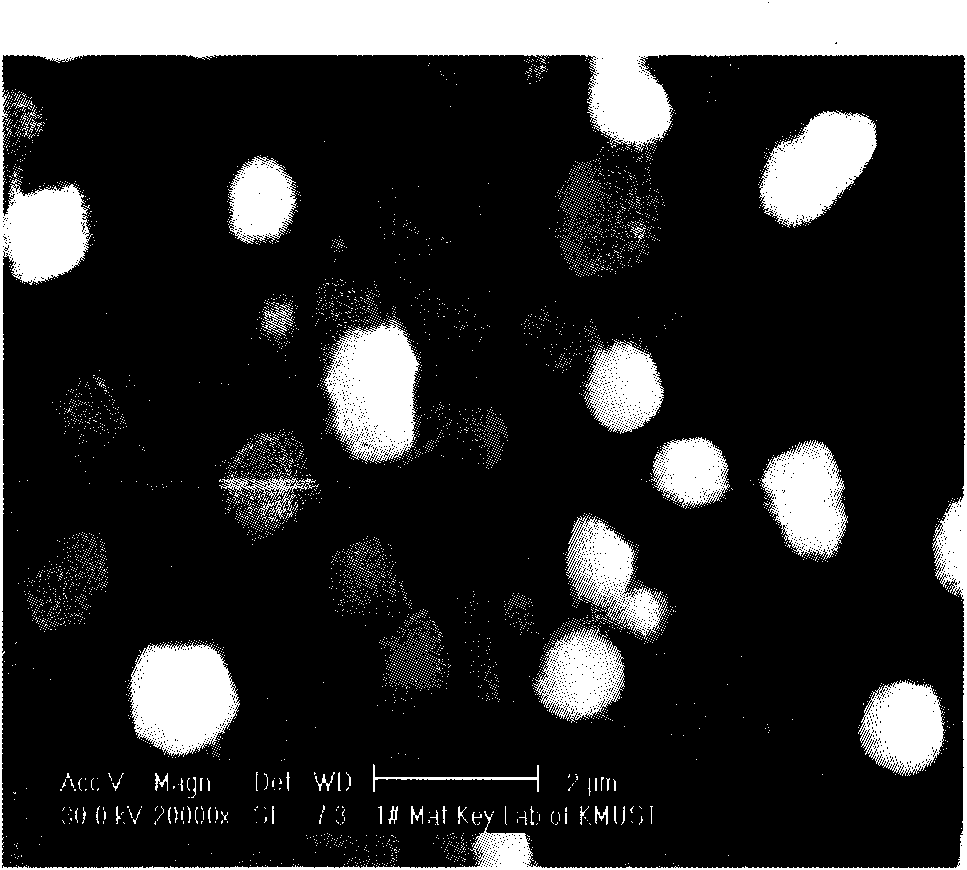

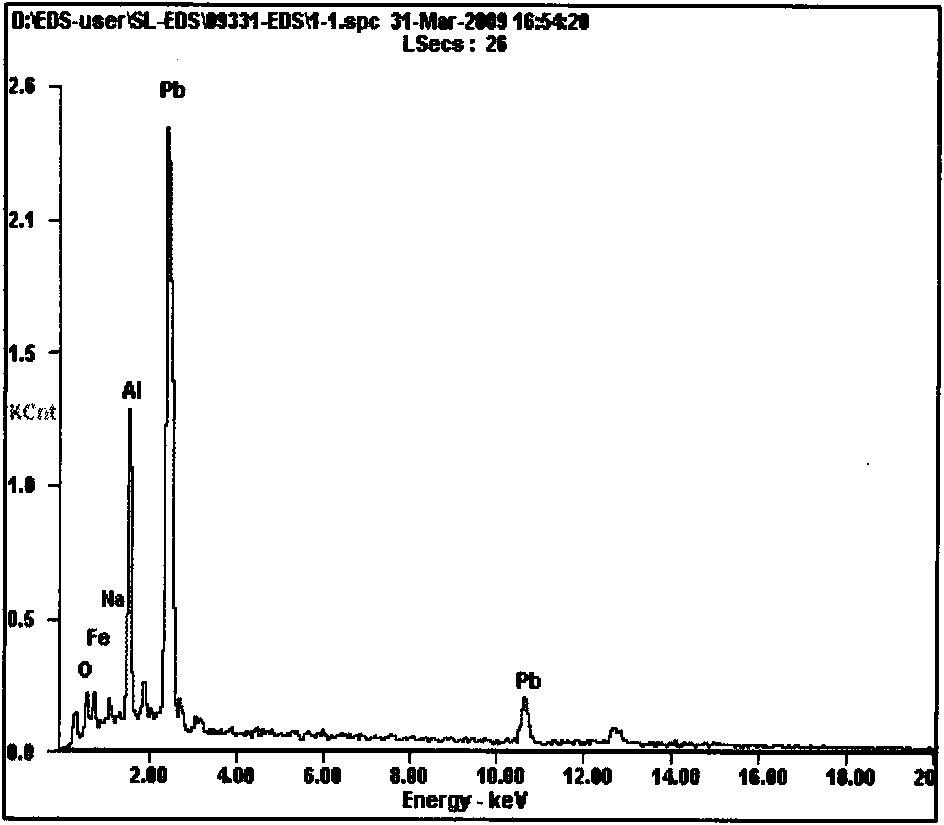

[0044] Embodiment 1 adopts [BMIM]PF 6 As for the ionic liquid in a vacuum glove box, lead nitrate was added in a molar ratio of 50:1, the electromagnetic stirring rate was 80 rpm, and the time was 2 hours, and the filtrate was obtained by filtration. Take 200ml of the filtrate and put it in the electroplating container, heat it in a water bath to 40°C, and the electromagnetic stirring speed is 120 rpm. The anode is made of pure lead plate with a size of 60mm×20mm×1mm, and the cathode is made of pure aluminum with a size of 60mm×10mm×1mm. Cell voltage is 1.5V, current density is 15A / m 2 , Plating time 2 hours. After the electroplating is finished, the metal base material is taken out from the plating tank, washed with acetone-water-acetone respectively, and dried to obtain a dense black lead plating layer.

[0045] The SEM microscopic appearance of the coating is as follows: figure 1 As shown, its composition is as figure 2 EDX results are shown.

Embodiment 2

[0046] Embodiment 2: Using [EMIM]BF 4 As for the ionic liquid in a vacuum glove box, lead acetate was added at a molar ratio of 60:1, and the electromagnetic stirring rate was 80 rpm for 2 hours, and the filtrate was obtained by filtration. Take 200ml of the filtrate and place it in the electroplating container, the operating temperature is room temperature, and the electromagnetic stirring rate is 120 rpm. The anode is made of pure lead plate with a size of 60mm×20mm×1mm, and the cathode is made of red copper with a size of 60mm×10mm×1mm. Cell voltage is 1.0V, current density is 10A / m 2 , Plating time 1 hour. After the electroplating is finished, the metal base material is taken out from the plating tank, washed with acetone-water-acetone respectively, and dried to obtain a dense black lead plating layer. The SEM microscopic appearance of the coating is as follows: image 3 As shown, the EDX results of its components are as follows Figure 4 shown.

Embodiment 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the molar ratio of ionic liquid to lead nitrate is 23:1, the anode adopts metal platinum plate, the cell voltage is 2.2V, and the current density is 20A / m 2 , Plating time 2 hours. Other steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com