Ultraviolet resistance mortar composite

An anti-ultraviolet and composition technology, which is applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, dyed high-molecular organic compounds, etc., can solve the main effect of mortar performance, mortar surface pulverization, and easy fission, etc. problems, to achieve the effect of eliminating powdering and peeling of the mortar surface, increasing compressive and flexural strength, and good finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

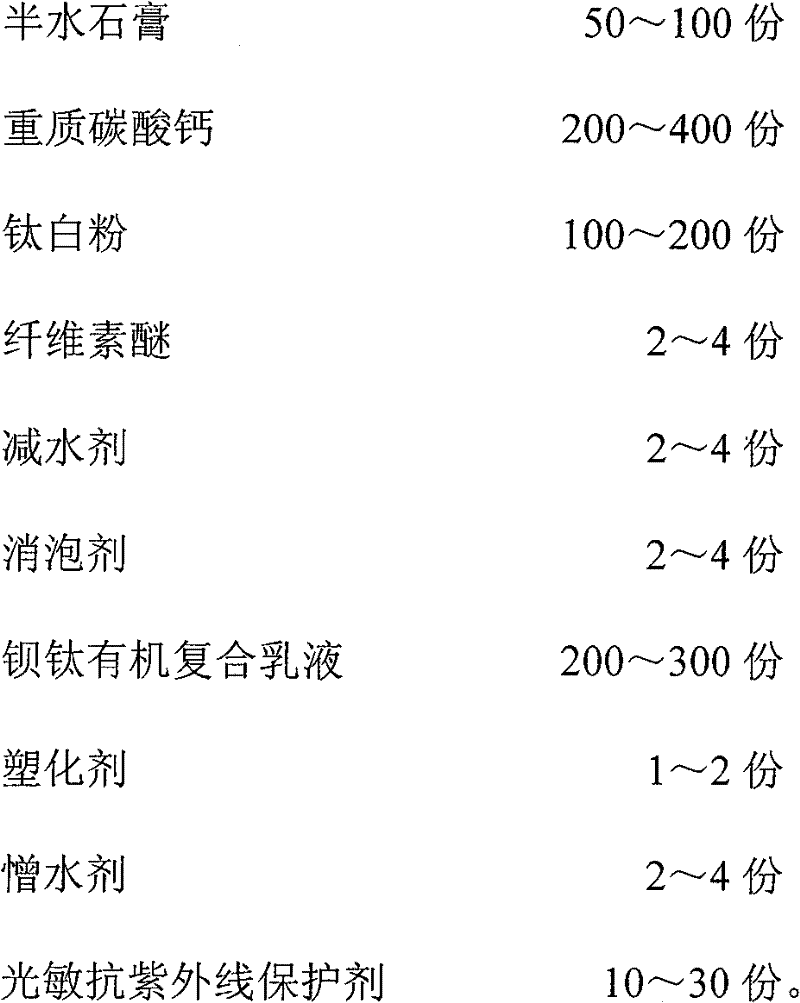

[0047] formula:

[0048] 400 parts of white cement, 100 parts of hemihydrate gypsum, 400 parts of heavy calcium carbonate, 100 parts of titanium dioxide, 2 parts of methyl cellulose ether, 2 parts of water reducer, 2 parts of defoamer, 200 parts of barium-titanium organic composite emulsion , 1 part of plasticizer, 2 parts of hydrophobic agent, 10 parts of photosensitive anti-ultraviolet protective agent, and 100 parts of water.

[0049]The water reducer is polycarboxylate water reducer, which is the product of Suzhou Xingbang Chemical Co., Ltd., the plasticizer is dibutyl phthalate, and the water repellent is DS-ZS 826 anion produced by Shanghai Dongsheng New Material Co., Ltd. Type dispersion water repellent, its chemical name for? ? ? ? ? ;

[0050] Preparation of barium-titanium organic composite emulsion:

[0051] (1) the rutile type nano-titanium dioxide of 8 weight parts, the water of 50 weight parts and the grafted gelatin of 3 weight parts are under pH 6.5, an...

Embodiment 2

[0069] formula:

[0070] 450 parts of white cement, 50 parts of hemihydrate gypsum, 350 parts of heavy calcium carbonate, 150 parts of titanium dioxide, 3 parts of methyl cellulose ether, 3 parts of water reducer, 3 parts of defoamer, 250 parts of barium-titanium organic composite emulsion , 1.5 parts of plasticizer, 3 parts of water-repellent agent, 20 parts of anti-ultraviolet protective agent, 110 parts of water;

[0071] The water reducer is polycarboxylate water reducer, which is the product of Suzhou Xingbang Chemical Co., Ltd., the plasticizer is dibutyl phthalate, and the water repellent is DS-ZS 826 anion produced by Shanghai Dongsheng New Material Co., Ltd. Type dispersion water repellent;

[0072] Preparation of barium-titanium organic composite emulsion:

[0073] (1) The rutile type nano-titanium dioxide of 6 weight parts, the water of 40 weight parts and the grafted gelatin of 1.5 weight parts are under pH 5.5, and 70 ℃ are made into gelatin solution, then add t...

Embodiment 3

[0089] formula:

[0090] 500 parts of white cement, 50 parts of hemihydrate gypsum, 250 parts of heavy calcium carbonate, 200 parts of titanium dioxide, 4 parts of methyl cellulose ether, 4 parts of water reducer, 4 parts of defoamer, 300 parts of barium-titanium organic composite emulsion , 2 parts of plasticizer, 4 parts of hydrophobic agent, 30 parts of photosensitive anti-ultraviolet protective agent, 110 parts of water;

[0091] The water reducer is polycarboxylate water reducer, which is the product of Suzhou Xingbang Chemical Co., Ltd., the plasticizer is dibutyl phthalate, and the water repellent is DS-ZS 826 anion produced by Shanghai Dongsheng New Material Co., Ltd. Type dispersion water repellent;

[0092] The preparation of the barium-titanium organic composite emulsion is the same as in Example 1.

[0093] Preparation of photosensitive anti-ultraviolet protective agent:

[0094] Prepare 100 parts of gelatin solution with a weight concentration of 1% at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com