Beta-glucosidase preparing method

A glucosidase and temperature control technology, applied in the field of preparation of β-glucosidase, can solve the problems of high cost and difficulty in large-scale production of non-food energy projects, achieve better enzymatic hydrolysis effect, improve mixing uniformity, reduce The effect of small losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

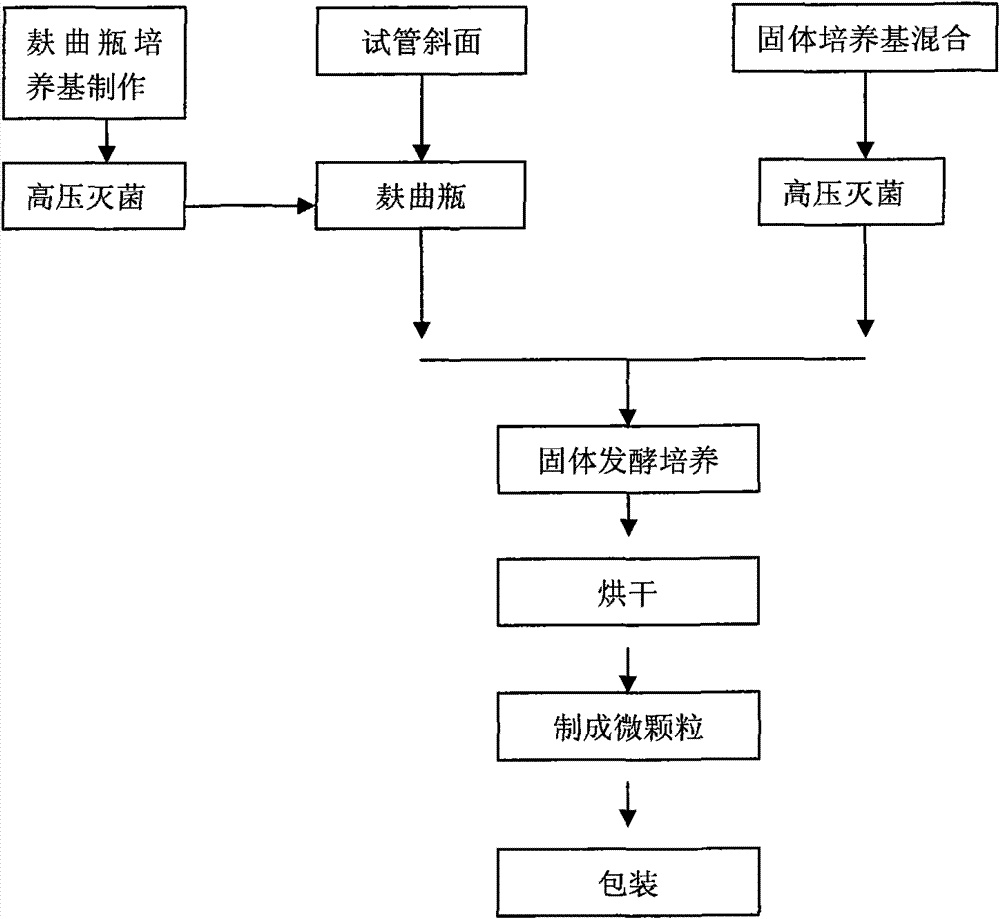

Method used

Image

Examples

Embodiment 1

[0020] Preparation of PDA slant medium: 200g peeled potatoes, chopped, add 1000ml water to boil for 30min, filter out the potato residue, add 20g sucrose to the filtrate, dissolve and set the volume to 1000ml, add 20g agar, boil to dissolve, then pack into test tubes, Cotton plugs, 7 in a group, wrapped with kraft paper, sterilized at 121°C for 20 minutes, waited for about 60-70°C, placed on a slope to cool and solidify, then put it in a 30°C incubator for 24 hours, check that there is no contamination use.

[0021] Take a ring from the refrigerated Aspergillus niger test tube, apply it to the inclined surface of the PDA test tube, place it in a constant temperature incubator at 30°C, cultivate it for 7-8 days, and put it in a 4°C refrigerator to refrigerate, then it can be used as the inclined plane seed.

Embodiment 2

[0023] The solid fermentation medium used in the method of the present invention contains per kilogram: corn cob 180g, bran 120g, ammonium sulfate 50g, urea 20g, magnesium sulfate 0.5g, potassium dihydrogen phosphate 0.1g, water 630g, and mix uniformly.

[0024] Put 120 g of the culture medium obtained above into a 1000 ml Erlenmeyer flask, seal it with a cotton plug, tie the mouth with kraft paper, and sterilize at 121° C. for 60 min. Take a loop of spores on the slant of the PDA medium test tube to inoculate, and culture statically at 30°C for 4-6 days. After the bran koji is covered with dark brown mold spores and mature, it is ready for use.

Embodiment 3

[0026] The solid fermentation medium contains per kilogram: 180g corn cob, 120g bran, 50g ammonium sulfate, 20g urea, 0.5g magnesium sulfate, 0.1g potassium dihydrogen phosphate, 630g water, and mix well.

[0027] Fill the solid fermentation medium with 10kg in a 1m×1m×0.1m square pan, cover the lid, sterilize at 121°C for 60min, cool it and inoculate it with black spores of the mold in the triangular flask, the inoculation amount is 2% of the weight of the solid medium Mix and inoculate with a mixer, then distribute 6kg per plate, and culture at 30°C. Water and moisturize the culture medium on the first day, and then continue to stand still for 3-4 days, dry and pulverize the cultured enzyme at 50°C and pass through a 200-mesh sieve to make enzyme powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com