Cadmium zinc oxygen alloy film and preparing method thereof

An alloy film and cadmium-zinc technology, applied in the field of cadmium-zinc-oxygen alloy film and its preparation, can solve the problems of inability to produce at low cost, complex preparation process, expensive equipment and the like, and achieve simple and mature preparation process, good repeatability, The effect of inexpensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take the following process steps: 1) Ball mill the cadmium and zinc particles according to the atomic content ratio of 0:1, 1:9, 2:8, 3:7, 4:6, 5:5 and press them into cadmium with different components Zinc alloy target; 2) Clean and polish the silicon wafer, put it into the reaction chamber of the DC reactive magnetron sputtering device, and the vacuum degree of the reaction chamber is pumped to 5×10 -3 Pa, with cadmium-zinc alloys of different components as targets, a cadmium-zinc-oxygen alloy film with a thickness of about 300nm was deposited on a silicon wafer by reactive direct current sputtering. During sputtering, the substrate temperature was 500°C, The radiation power is 80w, the flow rate is 30 and 15sccm, and the working pressure is 10Pa.

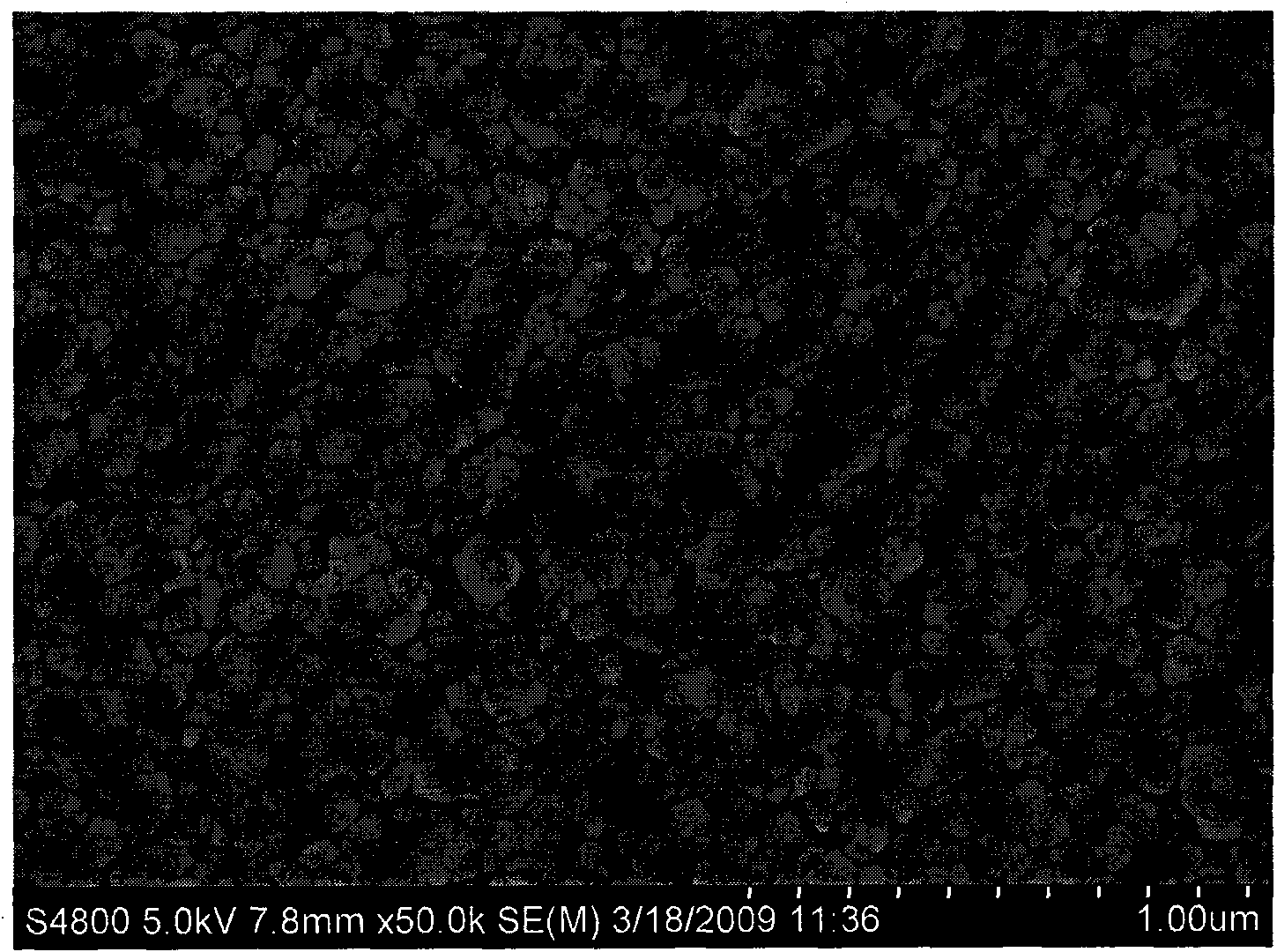

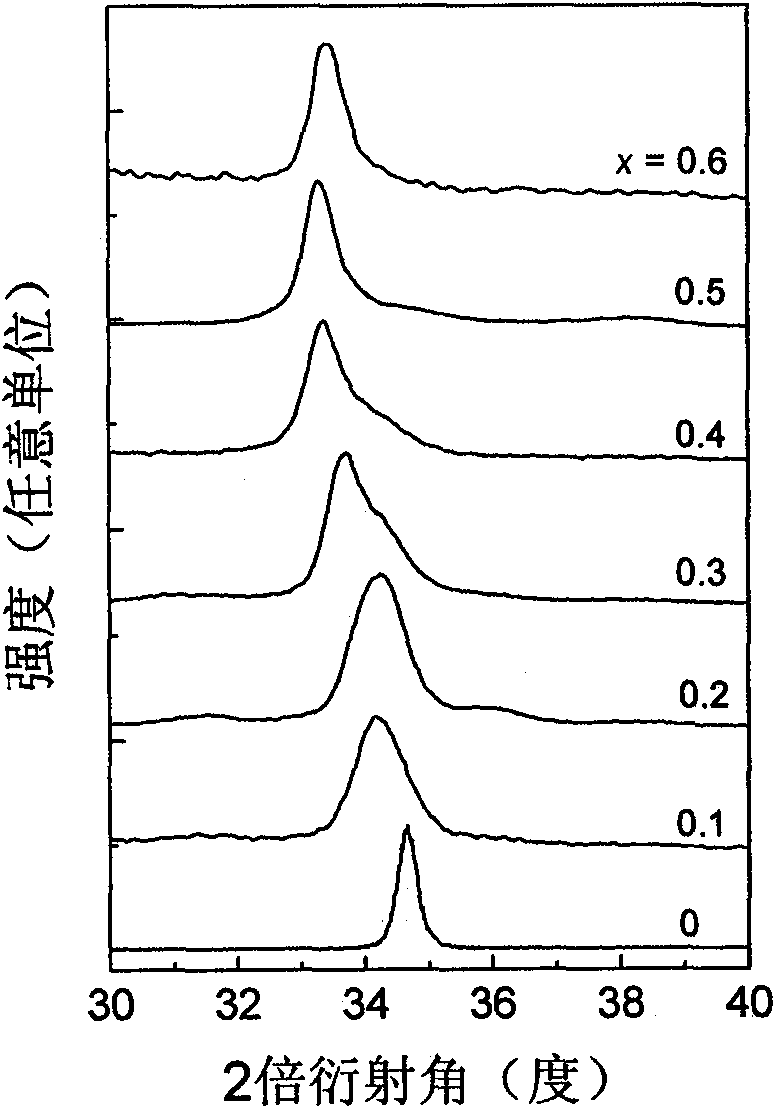

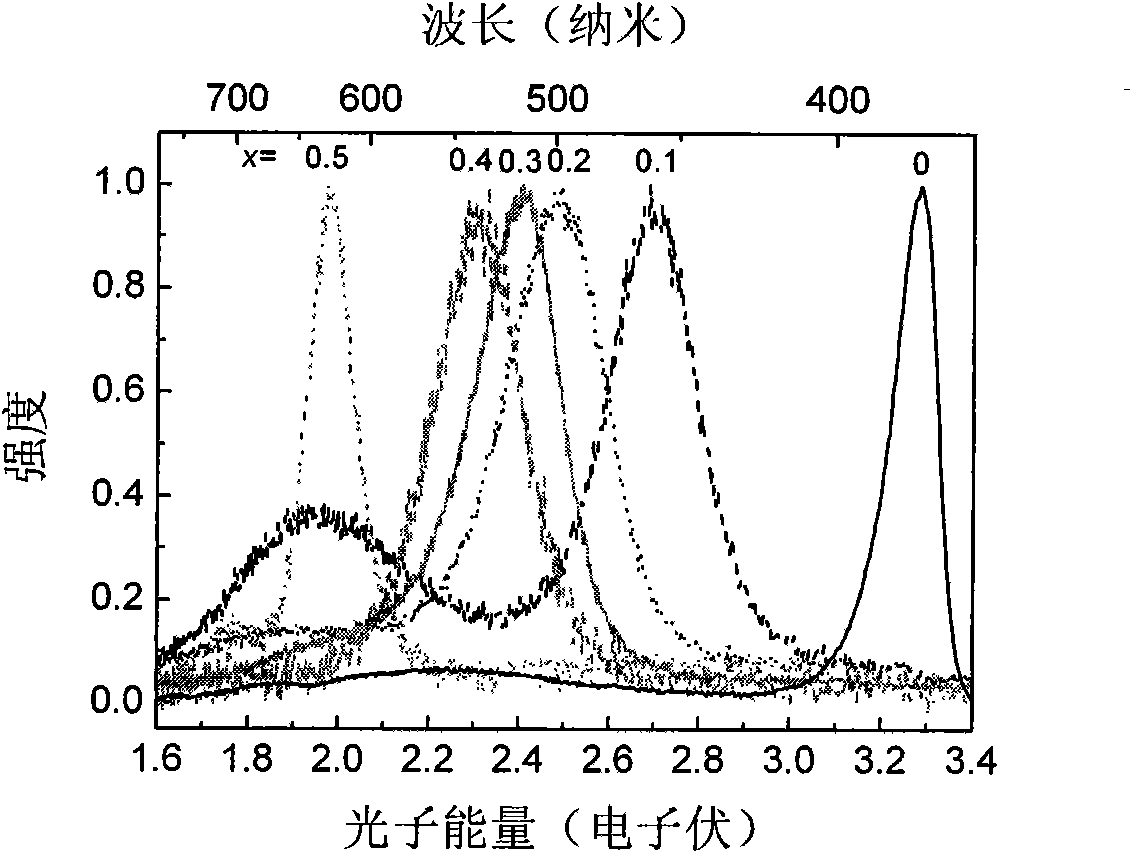

[0019] figure 1 The standard morphology of the prepared cadmium-zinc-oxygen alloy film is given, and it can be seen from the figure that the film is a hexagonal polycrystalline film. figure 2 The X-ray diffraction patte...

Embodiment 2

[0021] Take the following process steps: 1) Ball mill the cadmium and zinc particles according to the atomic content ratio of 0:1, 1:9, 2:8, 3:7, 4:6, 5:5 and press them into cadmium with different components Zinc alloy target; 2) Clean the double-sided polished quartz sheet, put it into the reaction chamber of the DC reactive magnetron sputtering device, and the vacuum degree of the reaction chamber is pumped to 3×10 -3 Pa, with different components of cadmium-zinc alloy as the target, a cadmium-zinc-oxygen alloy film with a thickness of about 200nm was grown on a quartz plate by DC reactive magnetron sputtering. During sputtering, the substrate temperature was 600°C, The radiation power is 100w, the flow rate is 20sccm with argon and oxygen, and the working pressure is 15Pa.

[0022] The absorption spectrum of the prepared cadmium-zinc-oxygen alloy thin film was measured, and (αhv) was obtained after calculation and transformation 2 The relationship curve with photon energy...

Embodiment 3

[0024] Take the following process steps: 1) ball mill cadmium oxide and zinc oxide according to the atomic content ratio of 0:1, 1:9, 2:8, 3:7, 4:6, 5:5 and press them into different components cadmium zinc oxide ceramic target; 2) cleaning the double-sided polished sapphire sheet, putting it into the reaction chamber of the radio frequency magnetron sputtering device, and the vacuum degree of the reaction chamber is pumped to 1×10 -3 Pa, using cadmium-zinc-oxygen ceramics with different components as the target material, a cadmium-zinc-oxygen alloy film with a thickness of about 500nm is grown on a sapphire wafer by sputtering. During sputtering, the substrate temperature is 750°C, the sputtering power is 120w, Argon gas (flow rate: 20sccm) is passed through, and the working pressure is 2Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com