Method of preparing gel polymer lithium ion battery

A technology of lithium-ion batteries and gel polymers, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of complex plasticizer extraction process, complex process, difficult to control, etc., and achieve a firm and stable internal structure of the battery cell , The process is simple, and the effect of reducing surface unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

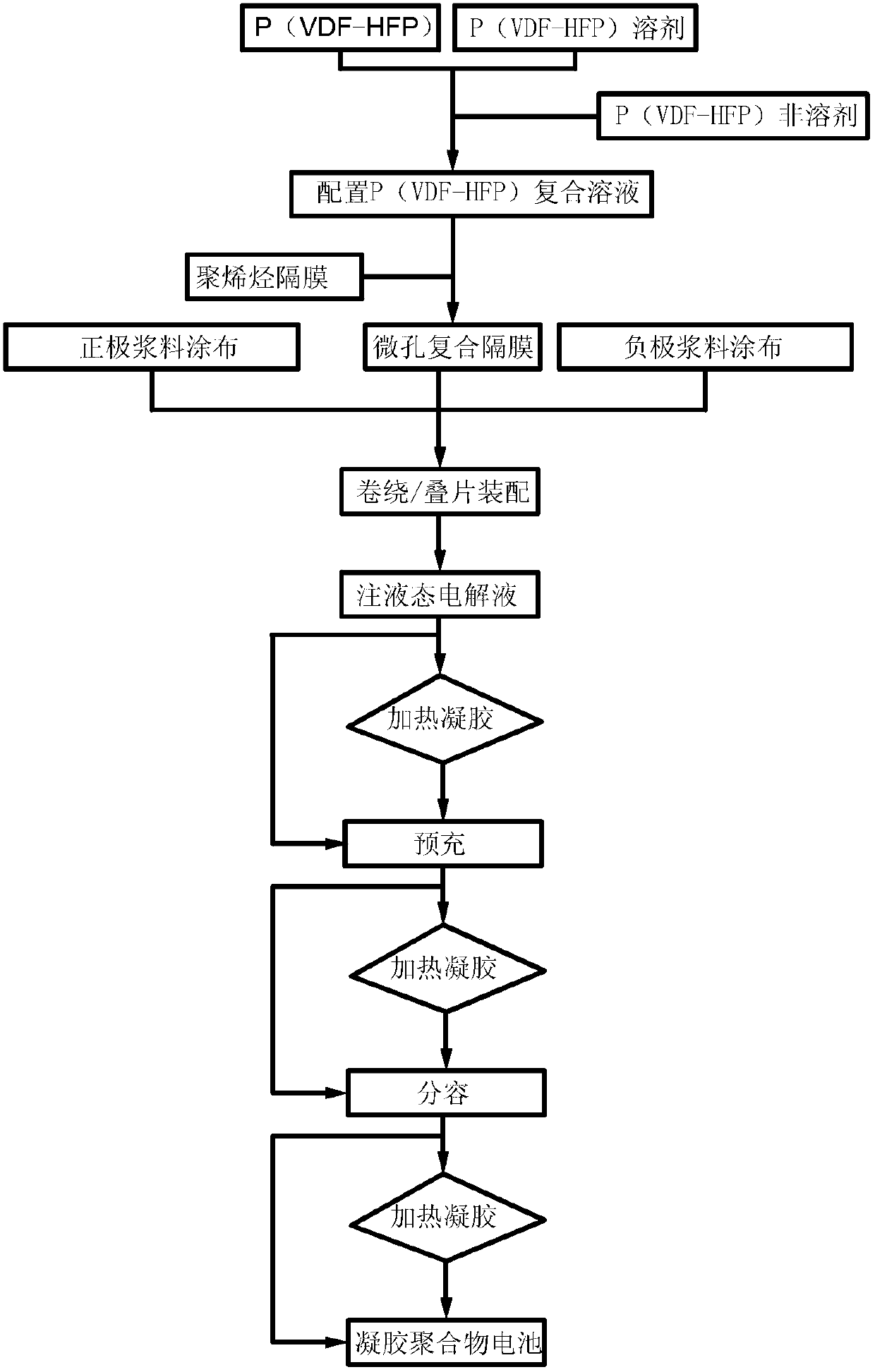

[0037] Prepare a kind of gel polymer lithium-ion battery, its preparation process is as follows figure 1 As shown, each material and component are as follows.

[0038] Cathode, LiCoO 2 : Acetylene carbon black conductive agent: PVDF binder (mass ratio) = 96: 1.6: 2.4; positive current collector is aluminum foil.

[0039] Negative electrode, artificial graphite: SBR binder: sodium carboxymethyl cellulose (mass ratio) = 96:2.5:1.5; negative electrode current collector is copper foil.

[0040] Separator, 42.5% porosity polyolefin separator, thickness 12 μm.

[0041] Liquid electrolyte, EC: DEC: PC (mass ratio) = 1: 1: 0.2, LiFP 6 = 1M.

[0042] P(VDF-HFP) mixed solution, P(VDF-HFP): acetone: n-butanol: acetate ethanol (mass ratio) = 1:12:3:1; among them, monomeric HFP in P(VDF-HFP) The mass ratio to VDF is 13:100.

[0043] Prepare liquid electrolyte and P(VDF-HFP) mixed solution according to the above ratio.

[0044] The prepared P(VDF-HFP) mixed solution is coated on the ...

Embodiment 2

[0060] A gel polymer lithium ion battery was prepared. The difference between the materials and components of Example 1 was that in the prepared P(VDF-HFP) mixed solution, the solvent was a combination of acetone and tetrahydrofuran, and the non-solvent was positive Butanol, the proportion is, P(VDF-HFP): acetone: tetrahydrofuran: n-butanol (mass ratio) = 1:6:6:4.

[0061] Its preparation process differs from Example 1 in that the prepared solution P(VDF-HFP) mixed solution is coated on the positive electrode sheet of the battery, thereby forming a composite porous membrane on the positive electrode sheet of the battery instead of forming a porous film on the separator. composite porous membrane.

[0062] A set of batteries was produced according to the above method, and the battery safety performance test was carried out by using the method in Example 1, and the battery test results were qualified.

Embodiment 3

[0064] Prepare a kind of gel polymer lithium ion battery, each material and component are different from embodiment 1 in that, in the prepared P(VDF-HFP) mixed solution, solvent adopts dimethylformamide, non-solvent adopts acetic acid Ethanol, the ratio is, P(VDF-HFP): dimethylformamide: ethyl acetate (mass ratio) = 5:100:30.

[0065] Its preparation process is identical with embodiment 1.

[0066] A set of batteries was produced according to the above method, and the battery safety performance test was carried out by using the method in Example 1, and the battery test results were qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com