Method of preparing three-dimensionally ordered macroporous chelate resin with hydrophilic-structure framework

A three-dimensional ordered, chelating resin technology, used in chemical instruments and methods, other chemical processes, etc., can solve the problems of easy loss, softness, instability, etc., and achieves low diffusion resistance, large adsorption capacity, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

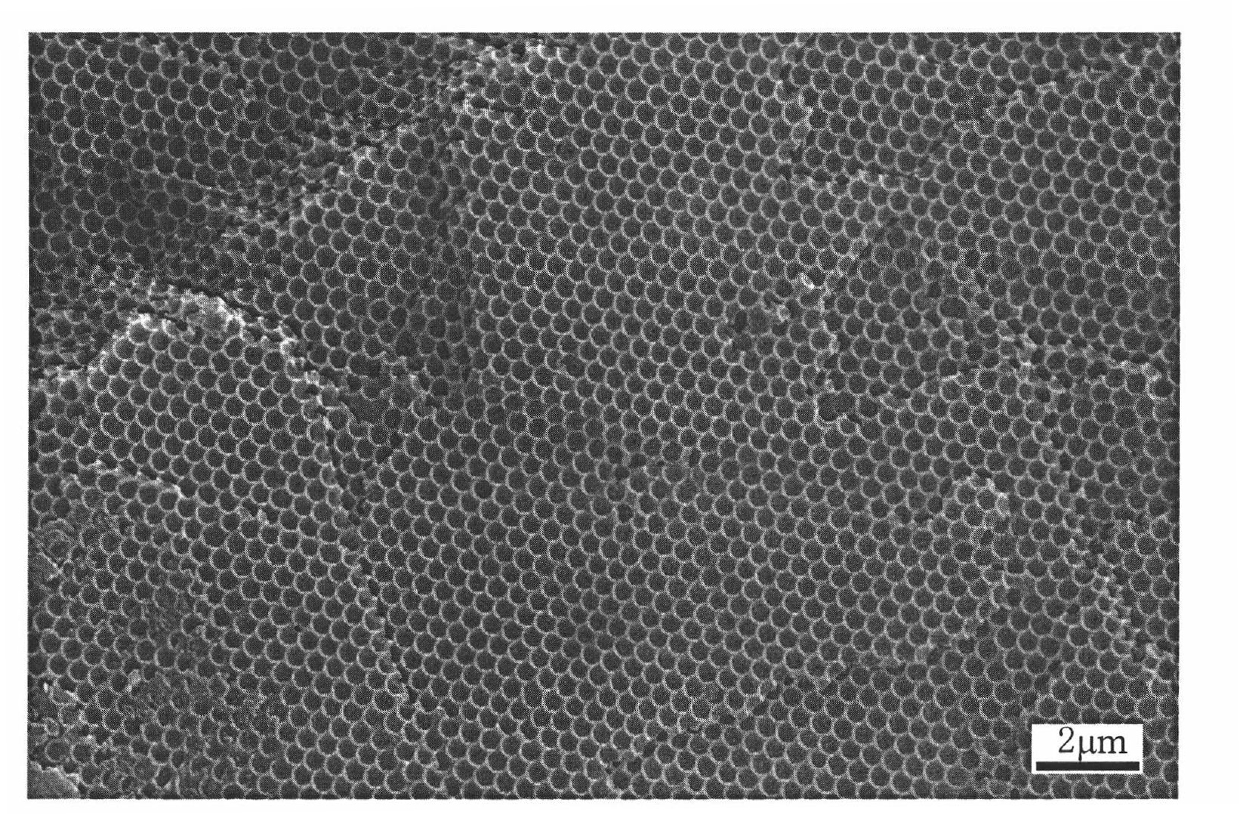

[0030] Preparation of Three-Dimensional Ordered Macroporous Polyethyleneamine Chelating Resin with Average Pore Diameter of 200nm

[0031] (1) Preparation of silica template

[0032] At room temperature, add 12.5g of absolute ethanol, 6.2g of 25% ammonia water, and 15.0g of distilled water in sequence in a three-necked flask equipped with electric stirring. After stirring evenly, quickly add 14.5g of ethyl orthosilicate, and stir. When the solution becomes turbid and no longer changes, that is, the hydrolysis reaction of tetraethyl orthosilicate is completed, then pour the obtained suspension into a 500mL beaker, and the solvent will evaporate naturally at room temperature, and then sinter the template at 200°C in a horse-boiling furnace After 2 hours, it was slowly lowered to room temperature to obtain a silica colloidal crystal template with an average particle size of 200 nm.

[0033] (2) Preparation of three-dimensional ordered macroporous poly N-vinyl formamide macroporous...

Embodiment 2

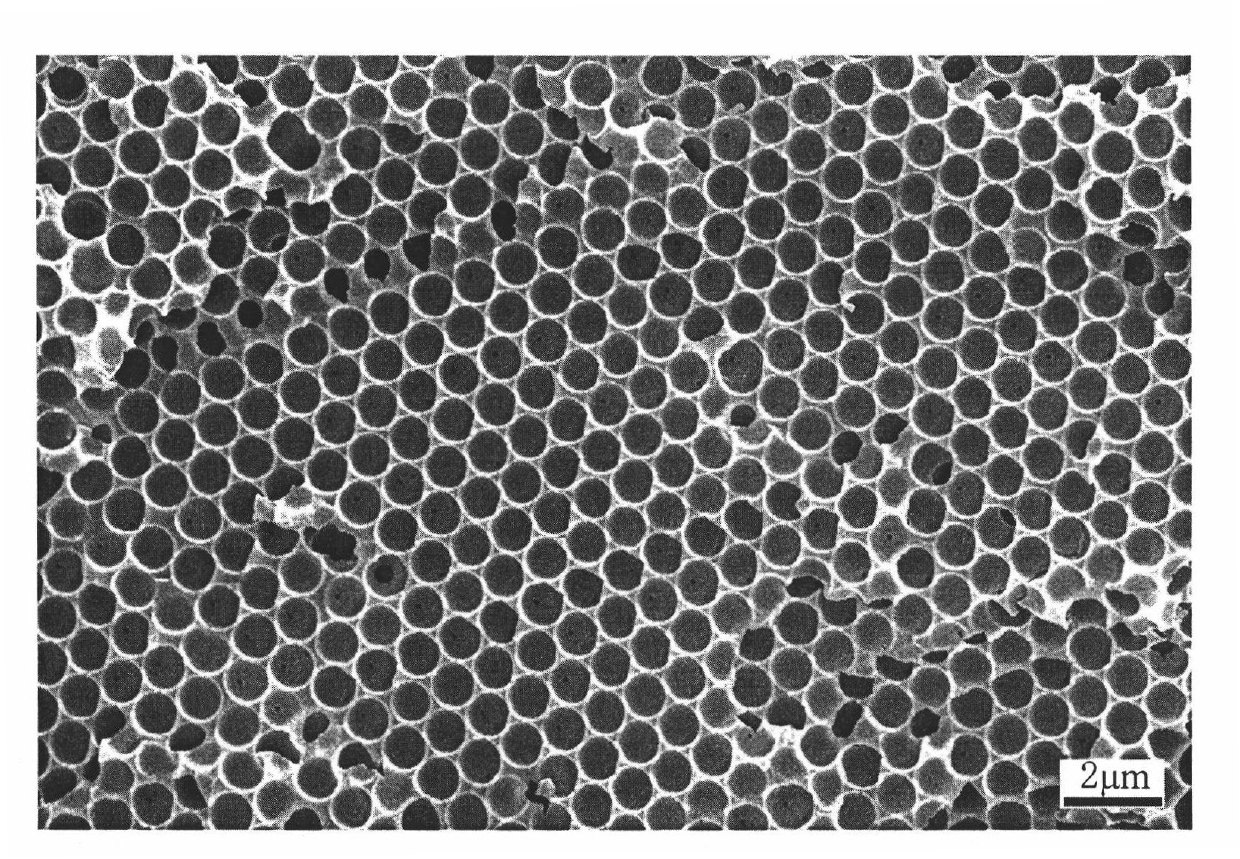

[0042] Preparation of Three-Dimensional Ordered Macroporous Polyethyleneamine Chelating Resin with Average Pore Diameter of 350nm

[0043] (1) The preparation method of silica colloidal crystal template is the same as that of Example 1 step (1), changing the quality of ammonia water, dehydrated alcohol, distilled water, and tetraethyl orthosilicate to 7.5g, 13.8g, 13.5g, 12.8g respectively , to obtain a silica colloidal crystal template with a template particle size of 350 nm.

[0044] (2) Add 0.1g blocky average grain through the colloidal crystal template that the silica microspheres in the range of 350nm adhere to each other in the two-necked bottle, inject 8.30g N-vinylacetamide monomer, 1.66g N, N sub- A mixture of methacrylamide and 0.01g of potassium persulfate is immersed in the colloidal crystal template, soaked for half an hour, heated up to 60°C, and reacted at this temperature for 12h to obtain silica / crosslinked polyethylene N-ethylene Based on the complex of ace...

Embodiment 3

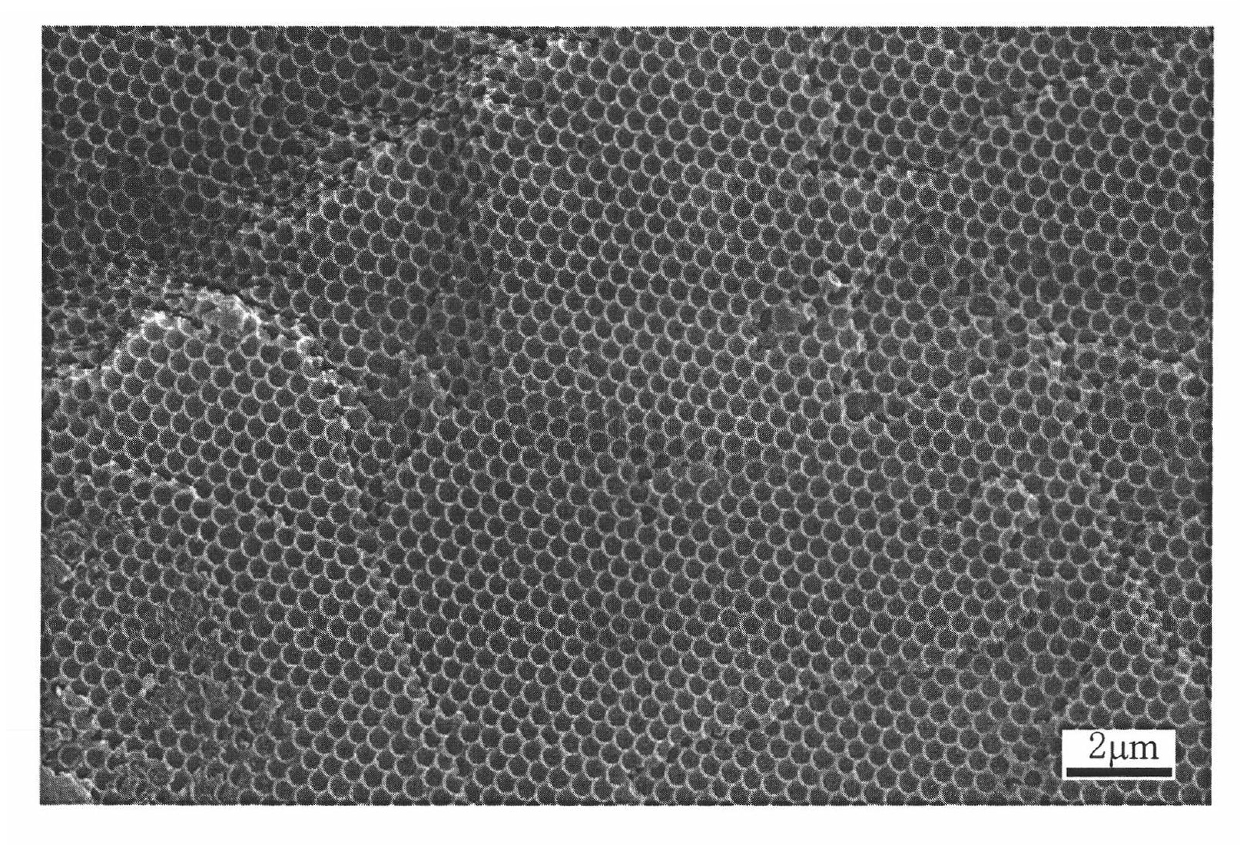

[0049] Preparation of Three-Dimensional Ordered Macroporous Polyethyleneamine Hydrophilic Chelating Resin with Average Pore Diameter of 500nm

[0050] (1) The preparation method of the silica colloidal crystal template is the same as that of Example 1 step (a), except that the quality of ammonia water, absolute ethanol, distilled water, and tetraethyl orthosilicate is changed to 7.5g, 13.8g, 12.5g, and 13.8g respectively. g, to obtain a silica colloidal crystal template with a template particle size of 500 nm.

[0051] (2) Add 0.1g block-like colloidal crystal templates with silica microspheres in the range of 500nm to each other in the two-necked bottle, inject 5.90g N-vinyl formamide monomer, 1.50g diethylene triethylene The mixed solution of amine and 0.0092g ammonium persulfate is immersed in the colloidal crystal template, soaked for half an hour, heated up to 60°C, and reacted at this temperature for 12h to obtain a composite of silica / cross-linked poly N-vinyl formamide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com