Preparation method for temperature sensing cornea epithelial cell culture material and application

A corneal epithelial cell, sensitive technology, applied in the direction of animal cells, vertebrate cells, artificial cell constructs, etc., can solve the problems of high cost of temperature-sensitive cell culture plates, to avoid cell function damage, broad application prospects, growth effect in good condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

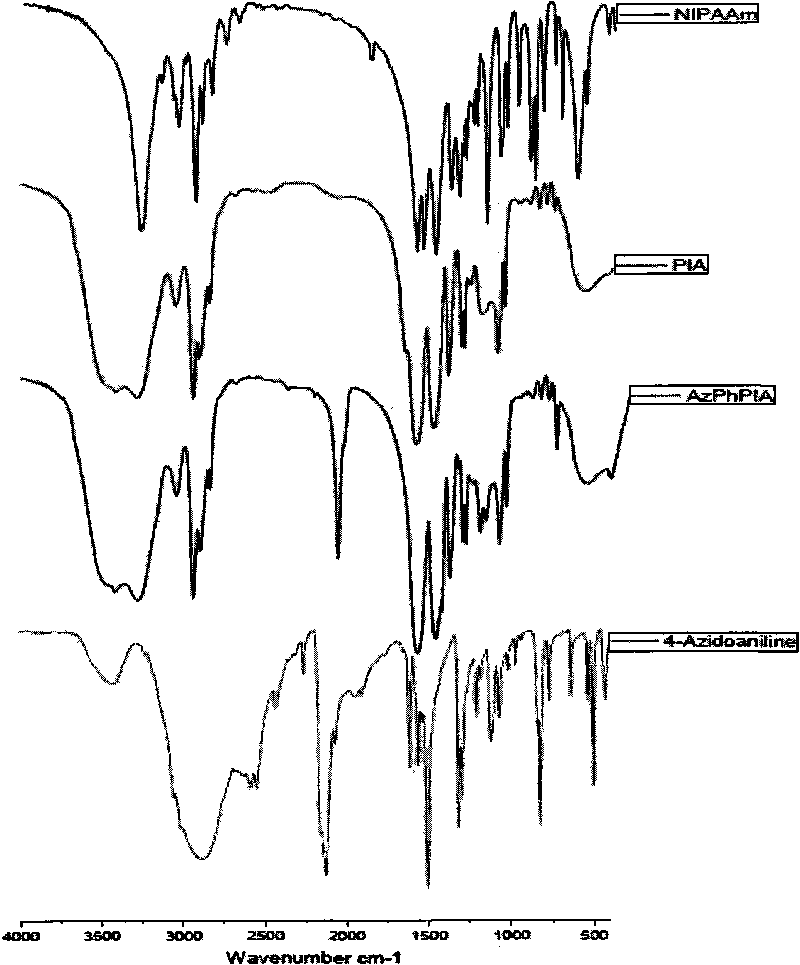

[0039] The structural characterization of the azidoaniline derivative of embodiment 1N-polyisopropylacrylamide / acrylic acid

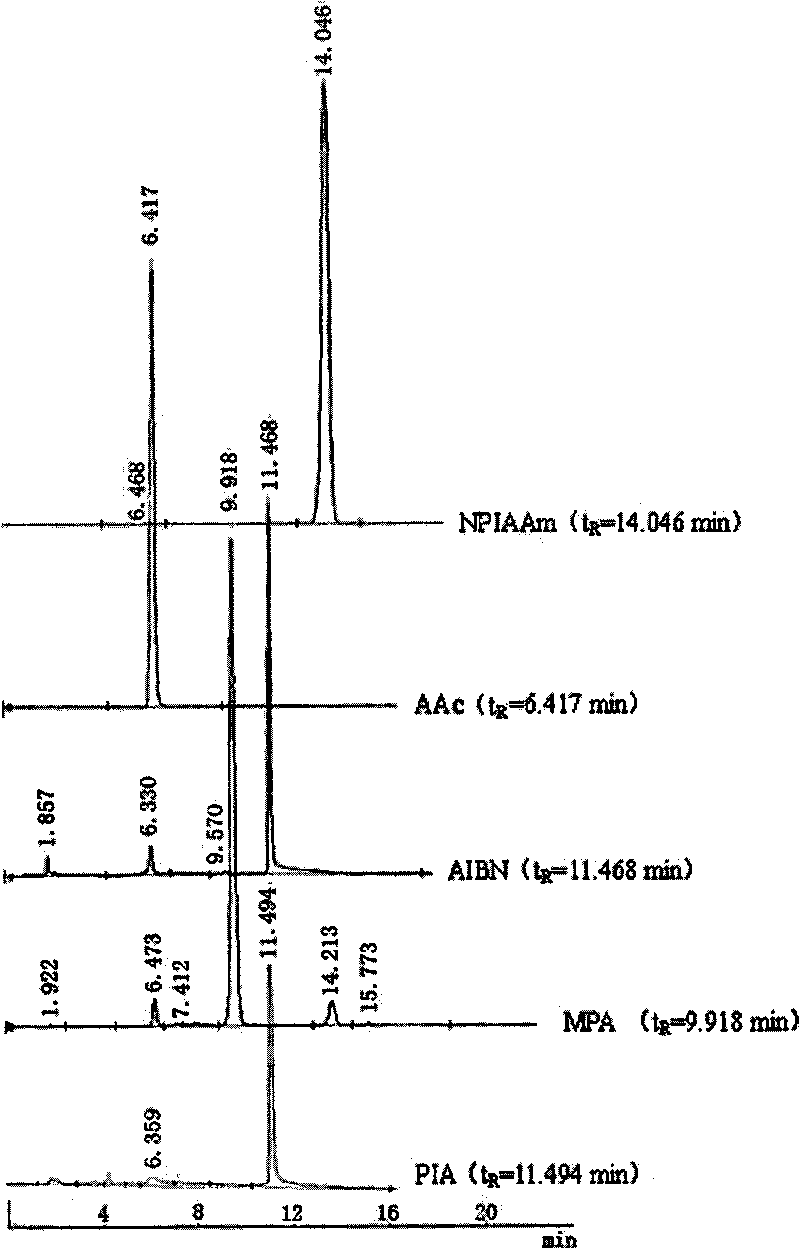

[0040] The reaction for preparing N-isopropylacrylamide / acrylic acid is a free radical polymerization reaction, once initiated, it goes through more thoroughly, and the residual amount of monomer is very small. In addition, during the experiment, the reaction ratio of the monomers was strictly controlled, and refined by methanol dilution and ether precipitation to remove unreacted monomers, initiators and chain transfer agents, so the influence of reactant residues on the test results can be basically eliminated . Use Japan Shimadzu LC-6A high performance liquid chromatograph to detect reactant (N-isopropylacrylamide monomer, acrylic acid, 3-mercaptopropionic acid, azobisisobutyronitrile) and product (N-isopropylacrylamide acrylamide / acrylic acid). High-performance liquid chromatography analysis conditions: at room temperature, use a 7125 manual injec...

Embodiment 2

[0044] Temperature-sensitive properties and turbidity of the azidoaniline derivative material of embodiment 2N-isopropylacrylamide / acrylic acid

[0045] image 3 It reflects the phase transition process of N-isopropylacrylamide in the range of 0-60℃. The aqueous solution of N-isopropylacrylamide is basically transparent below 30°C, and becomes turbid as the temperature rises, that is, phase separation occurs. As the temperature further increases, the degree of turbidity gradually increases until it becomes turbid around 40°C reached stability. When the temperature drops to 30°C again, the cloudy solution can become transparent again, it can be seen that its L°CST is in the range of 30-35°C. Since the main chain of the N-isopropylacrylamide molecule is connected with a carboxyl group, it has strong hydrophilicity, so that the solution is only turbid after the phase separation of the N-isopropylacrylamide side chain, and no precipitation occurs. The result of chain phase sepa...

Embodiment 3

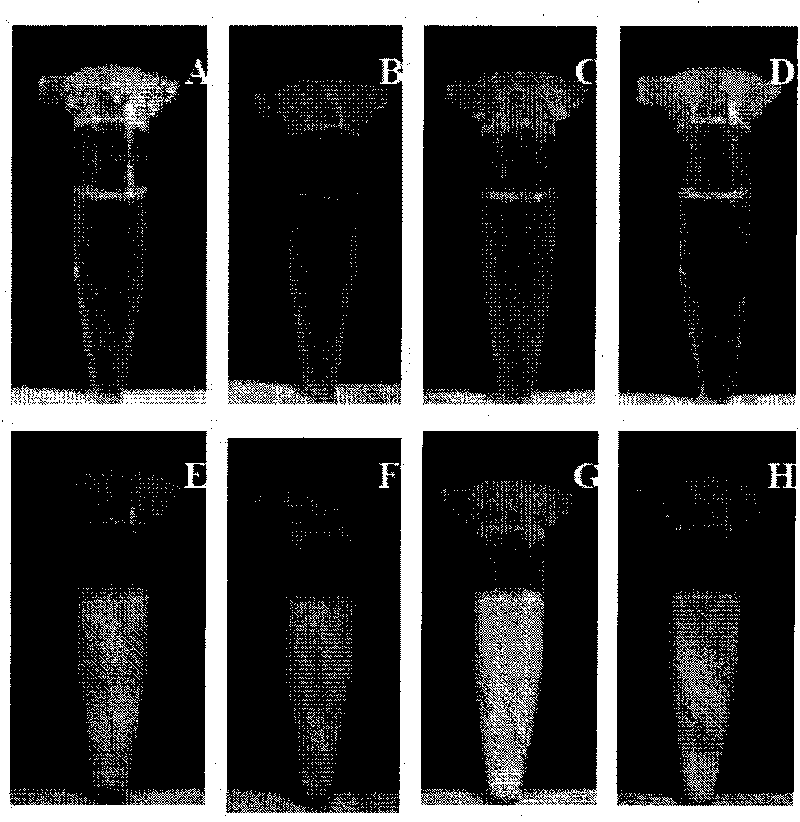

[0050] Example 3 Thermosensitivity test of culture plates immobilized with N-isopropylacrylamide / acrylic acid azidoaniline derivatives

[0051] When preparing temperature-sensitive polystyrene culture plates, add the N-isopropylacrylamide / acrylic acid azidoaniline derivative solution at 20 μl / well and dry at 10°C. During the whole process of the ultraviolet photochemical grafting reaction, it is necessary to ensure that the experimental temperature is always lower than the LCST (21.5° C.) of the azidoaniline derivative of N-isopropylacrylamide / acrylic acid. The low concentration of sample addition is because the monomer concentration is too high, which will lead to increased homopolymerization and chain termination reactions, which will reduce the grafting rate. The reaction after drying is due to the strong absorption of ultraviolet light by the monomer containing azo chromophore, and the grafted film cannot be obtained by the usual liquid phase grafting method. Keep the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com