Method and device of removing boron in polysilicon by local evaporation

A polysilicon, local technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of inability to remove segregation coefficient, long process time, low primary conversion rate, etc. Technical bottleneck, good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

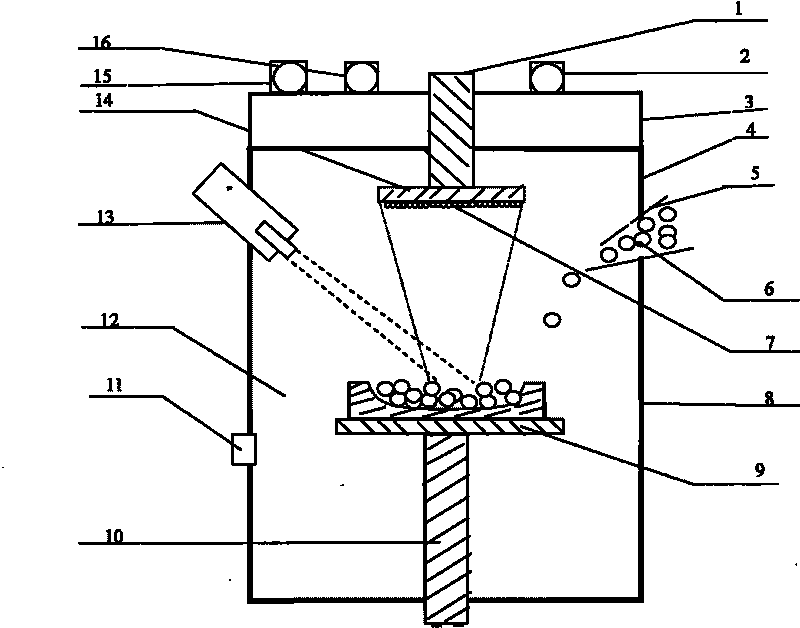

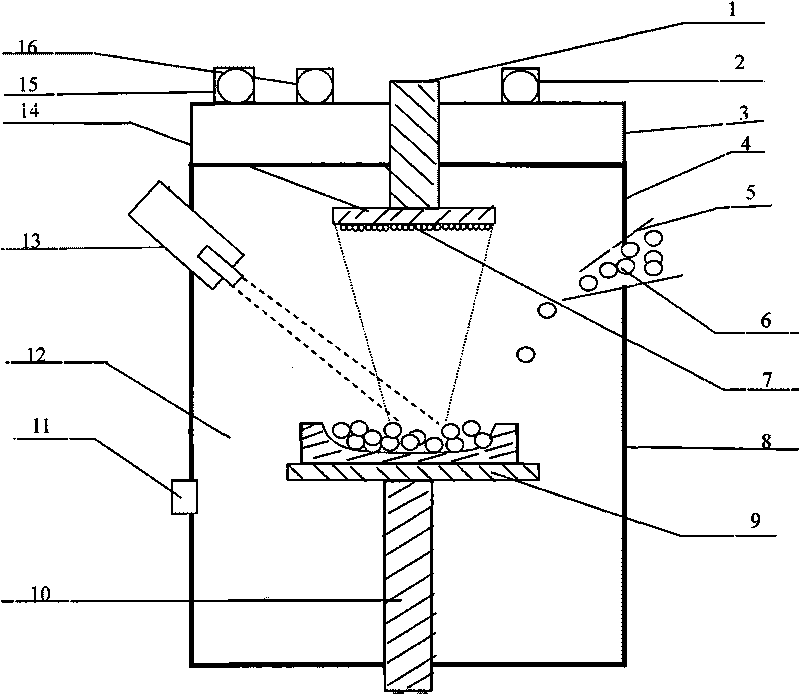

[0018] The specific implementation of this solution will be described in detail below in conjunction with the technical solution and accompanying drawings.

[0019] According to the Langmuir equation, where ω B is the evaporation rate, P B is the saturated vapor pressure of boron, M B is the atomic weight of boron atom, T is the molten pool temperature, γ B(l)inSi o is the activity coefficient of boron in silicon. Since the saturated vapor pressure of boron is very low, when silicon is smelted at high temperature, the boron contained in the silicon vapor is only less than one percent of the silicon matrix, and the evaporated silicon vapor is deposited to achieve the purpose of removing boron.

[0020] Put the high-boron polysilicon 6 with a boron content of 0.0005% into the graphite crucible 8, close the vacuum cover 3, and vacuumize the vacuum chamber 12 to a low vacuum of 1Pa with the mechanical pump 2 and the Rhodes pump 15, and then use the The diffusion pump 16 pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com