Superhydrophobic surface material and special nano-particles thereof with core-shell structures

A super-hydrophobic surface and nanoparticle technology, applied in other chemical processes, microcapsule preparations, microsphere preparation, etc., can solve the problems of material constraints, inability to carry out large-scale production and application, and lack of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Dissolve 0.5g of polymethyl methacrylate in 20ml of dichloromethane, add 1.5g of calcium hydroxide, mix well and add 80ml of petroleum ether dropwise. Suction filter the obtained product, and repeatedly wash with petroleum ether for 3 to 4 times to obtain inorganic microcapsules.

[0048] 2. Coating α-ethyl cyanoacrylate on the glass sheet with the method of spin coating (2000 rpm, 20 seconds), after drying at room temperature for 30 minutes, the bionic micro-nano hierarchical structure obtained in step 1 The ethanol dispersion of the composite microspheres was spray-coated on the above-mentioned glass sheet, and continued to solidify at room temperature for 2 hours.

[0049] 3. Soak the coating prepared in step 2 in a solution of 1% potassium stearate by mass, react for 8 hours, and dry to obtain a surface material with superhydrophobic properties.

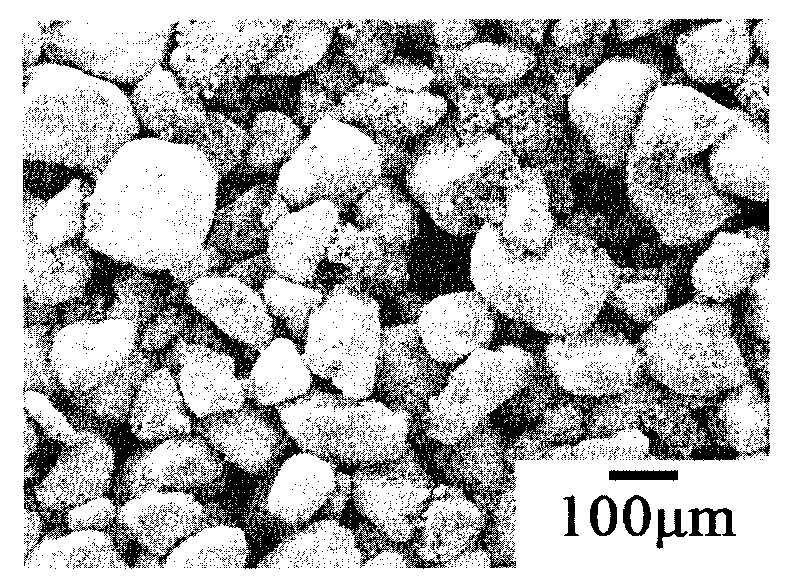

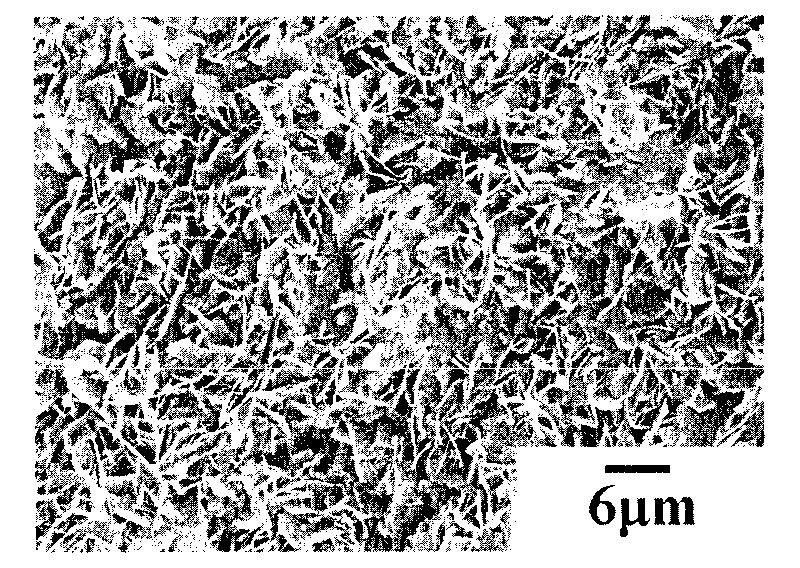

[0050] The scanning electron microscope photograph of this inorganic matter microcapsule is as attached figure 1 sh...

Embodiment 2

[0052] 1. Disperse 100 mg of polystyrene hollow microsphere aqueous solution (solid content is 27.5%) with a diameter of 1 micron in 30 ml of 2mol / L hydrochloric acid solution, add 3.6 ml of aniline monomer, mix well, and stir at room temperature for 24 hour, the homogeneous mixture obtained was centrifuged at a speed of 12000 rpm for 5 minutes, and the centrifuged isolate was dispersed in 0.2mol / L FeCl 3 aqueous solution, stirred at room temperature for 24 hours. Centrifuge at a speed of 8000 rpm and wash with water to obtain polyaniline-polystyrene composite microspheres with a diameter of 1 micron and a bionic micro-nano hierarchical structure.

[0053] 2. be the acetone solution of the F46 type novolac epoxy resin of 20% by weight percent concentration, select N for use, N-dimethylbenzylamine is as curing agent, and its weight is 10% of described epoxy resin weight, mixes, Coating film on the plexiglass plate with the method of spin coating (2000 rpm, 20 seconds), after d...

Embodiment 3

[0058] 1. Disperse 20 mg of polystyrene hollow microspheres with a diameter of 1 micron in water, centrifuge the emulsion at a speed of 12,000 rpm for 5 minutes after 24 hours, wash the isolate obtained by centrifugation twice with ethanol, and disperse in ethanol , add 0.2ml of mixed solution of n-butyl titanate and ethanol (the volume ratio of the two is 1:1) per hour, add 15 times in total, centrifuge the obtained mixed solution, wash it repeatedly with ethanol, and then wash it with polystyrene Washing with toluene solution for 2 to 3 times can obtain titanium dioxide hollow microspheres with columnar structure on the surface.

[0059] 2. be the acetone solution of the bisphenol A type epoxy resin (E51 type) of 20% by weight percent concentration, with the triethylenetetramine of epoxy resin weight 5% as curing agent, mix well, with the method of spin coating (2000 revs / min, 20 seconds) film coating on the plastic sheet, after drying at 60 ℃ for 10 minutes, the ethanol dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

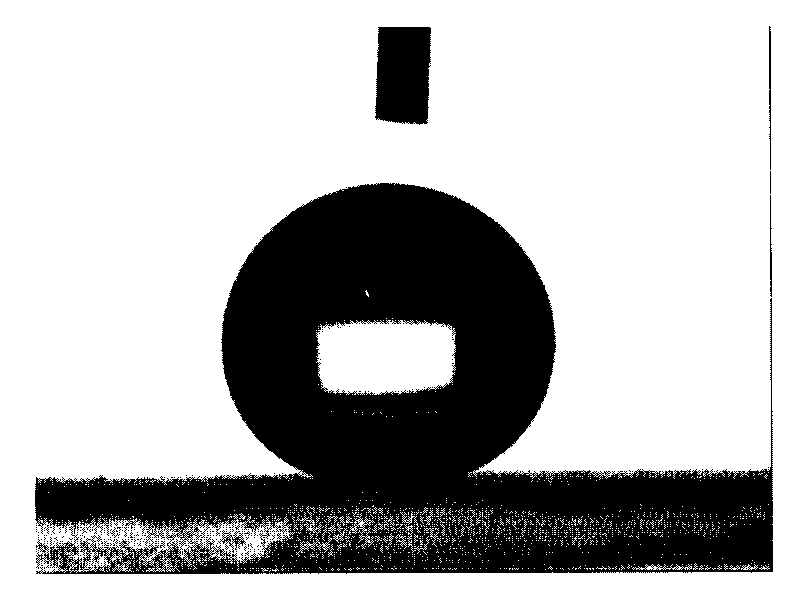

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com