Preparation method of visible light absorption type upper conversion luminescent material

A luminescent material and absorbing technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of no up-conversion luminescent material research report and other problems, and achieve the effects of uniform size, uniform doping and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

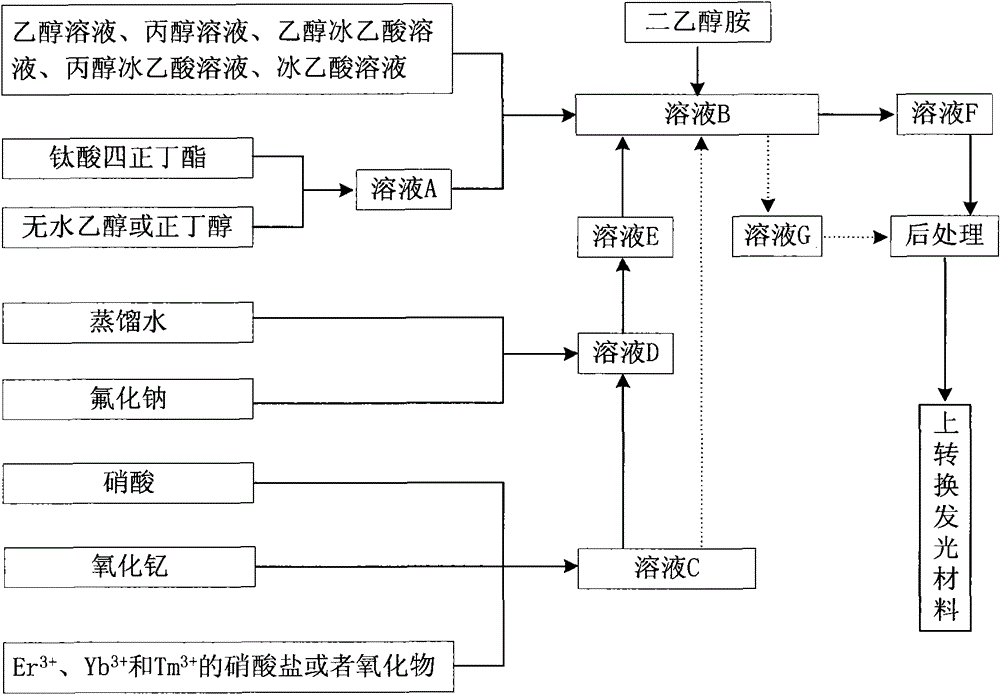

Method used

Image

Examples

preparation example Construction

[0039] The preparation of solutions B and E can be carried out at the same time. After 6-7 hours, slowly add solution E to solution B dropwise, and then stir at room temperature for another 2 hours to obtain solution F;

[0040] Aging the solution F to obtain the sol, drying the sol in a vacuum drying oven at 50-100°C to obtain a xerogel, after grinding, and then calcining at 200-500°C for about 2 hours, the heating rate is 10°C / min, and finally Grinding to obtain up-conversion powder luminescent material.

[0041] The present invention can also prepare up-conversion thin-film luminescent materials, and the specific method is as follows: the sol obtained in step 6 is used as a substrate with pre-treated clean glass or silicon wafers, and a film is formed by dipping and pulling method or spin coating method, and the thickness of the film is It can be adjusted by adjusting the pulling speed and the number of pulling times or the speed of the glue homogenizer; the wet film is dried...

Embodiment 1

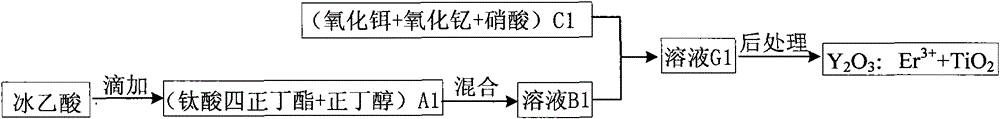

[0043] Embodiment 1: Preparation Y 2 o 3 :Er 3+ +TiO 2 up-conversion luminescent material

[0044] The raw materials used are as follows:

[0045]

[0046]

[0047] refer to figure 2 As shown, the preparation process of this embodiment is as follows:

[0048] 1) Add 7.4ml of n-butanol to 6.8ml of tetra-n-butyl titanate, mix and stir for 0.5 hours to obtain solution A1;

[0049] 2) Slowly drop 4.6ml of glacial acetic acid into solution A1, stir at room temperature for 6 hours to obtain solution B1, and continue stirring;

[0050] 3) Add 1.8mol of diethanolamine to solution B1 as a catalyst, and continue stirring;

[0051] 4) Weigh 0.7527g of yttrium oxide and 0.2532g of erbium oxide into a beaker, add 9.0ml of nitric acid, shake the beaker to obtain a turbid solution, stir the turbid solution at 100°C for 0.5 hour until the solution is complete, and obtain a clear nitric acid solution as C1, put the solution C1 at room temperature to cool;

[0052] 5) Stir the s...

Embodiment 2

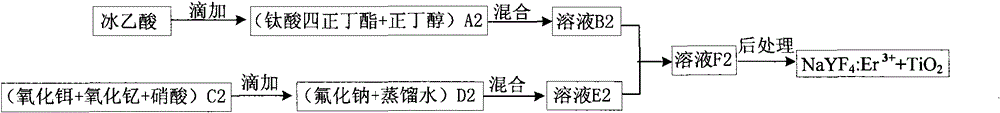

[0056] Embodiment 2: Preparation of NaYF 4 :Er 3+ +TiO 2 up-conversion luminescent material

[0057] The raw materials used are as follows:

[0058]

[0059]

[0060] refer to image 3 , the preparation process of the present embodiment is as follows:

[0061] 1) Add 7.4ml of n-butanol to 6.4ml of tetra-n-butyl titanate, mix and stir for 0.5 hours to obtain solution A2;

[0062] 2) slowly drop 4.6ml of glacial acetic acid into solution A2 to obtain solution B2, and continue stirring;

[0063] 3) Add 6.8 mol of diethanolamine as a catalyst to solution B2, and stir for 6 hours;

[0064] 4a) Weigh 0.7529g of yttrium oxide and 0.3072g of erbium oxide into a beaker, add 9.0ml of nitric acid, shake the beaker to obtain a turbid solution, stir the turbid solution at 100°C for 0.5 hours, and obtain a clear nitric acid solution as C2. C2 is cooled at room temperature;

[0065] 4b) 1.120g of sodium fluoride was dissolved in 19ml of distilled water to obtain solution D2;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com