Preparation process of levofloxacin hemihydrate

A technology of levofloxacin and a preparation process, which is applied in the field of preparation of levofloxacin hemihydrate, can solve the problems of unfavorable quality and yield of finished levofloxacin hemihydrate, affecting the normal function of a wastewater treatment station, and high requirements for a vacuum equipment system, so as to maintain production order. , The effect of complete crystal form and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

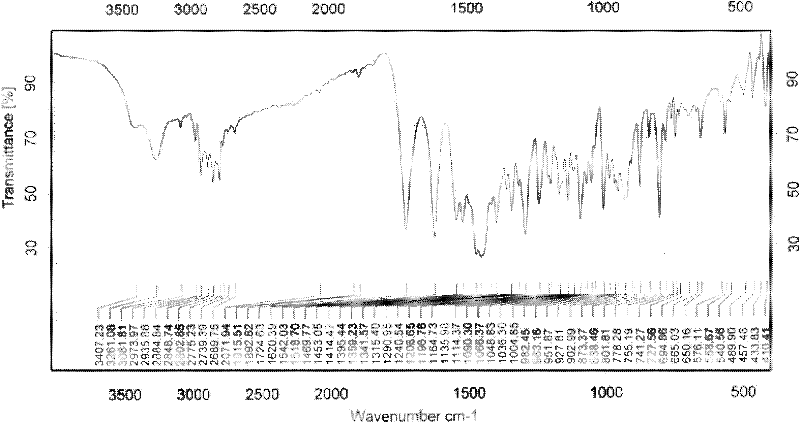

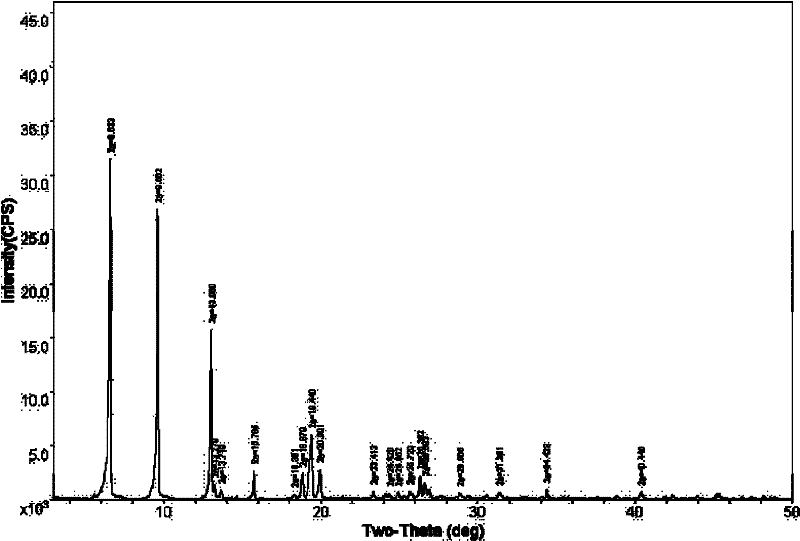

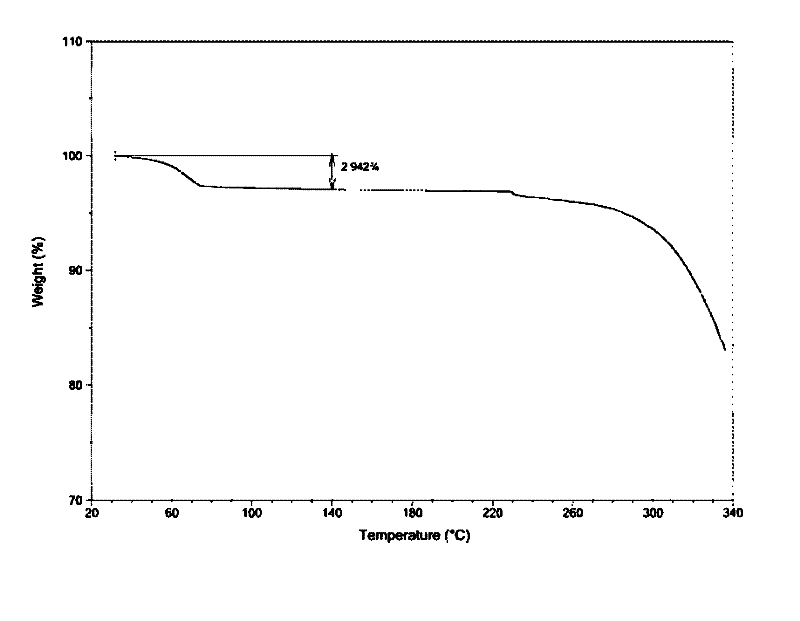

Image

Examples

Embodiment 1

[0031] Embodiment 1 Ethylene glycol mono-tert-butyl ether: water (190: 20, w / w)

[0032] 25 grams of levofloxacin (0.0889 moles), 20 grams of N-methylpiperazine (0.1997 moles) were dropped into 250 milliliters of reaction flasks equipped with a reflux device, then 40 grams of dimethyl sulfoxide was added, at 110 ℃ heat preservation reaction for 7 hours. After the reaction is complete, recover the solvent under reduced pressure to dryness, add 150 ml of water to the residue in the bottle, stir at 80-85°C until the system is basically clear, add 0.5 g of activated carbon, keep warm for 0.5 hours to decolorize, filter, and add 250 ml of water to the filtrate Chloroform, stirring and extracting for 1 hour, adjusting the pH value of the water layer to 7.0-8.0 with liquid alkali, stirring and washing the extracted oil layer with 100 ml of water for 15 minutes, standing still for 1 hour, separating the organic layer of chloroform, heating and recovering to dryness, to obtain Crude l...

Embodiment 2

[0033] Embodiment 2 ethylene glycol monoethyl ether: water (110: 9, w / w)

[0034]25 grams of levofloxacin (0.0889 moles), 20 grams of N-methylpiperazine (0.1997 moles) were dropped into 250 milliliters of reaction flasks equipped with a reflux device, then 40 grams of dimethyl sulfoxide was added, at 110 ℃ heat preservation reaction for 7 hours. After the reaction is complete, recover the solvent under reduced pressure to dryness, add 150 ml of water to the residue in the bottle, stir at 80-85°C until the system is basically clear, add 0.5 g of activated carbon, keep warm for 0.5 hours to decolorize, filter, and add 250 ml of water to the filtrate Chloroform, stirring and extracting for 1 hour, adjusting the pH value of the water layer to 7.0-8.0 with liquid alkali, stirring and washing the extracted oil layer with 100 ml of water for 15 minutes, standing still for 1 hour, separating the organic layer of chloroform, heating and recovering to dryness, to obtain Crude levofloxa...

Embodiment 3

[0035] Example 3 Ethylene glycol tert-ethyl ether: ethylene glycol monoethyl ether: water (70:50:10, w / w / w)

[0036] 25 grams of levofloxacin (0.0889 moles), 20 grams of N-methylpiperazine (0.1997 moles) were dropped into 250 milliliters of reaction flasks equipped with a reflux device, then 40 grams of dimethyl sulfoxide was added, at 110 ℃ heat preservation reaction for 7 hours. After the reaction is complete, recover the solvent under reduced pressure to dryness, add 150 ml of water to the residue in the bottle, stir at 80-85°C until the system is basically clear, add 0.5 g of activated carbon, keep warm for 0.5 hours to decolorize, filter, and add 250 ml of water to the filtrate Chloroform, stirring and extracting for 1 hour, adjusting the pH value of the water layer to 7.0-8.0 with liquid alkali, stirring and washing the extracted oil layer with 100 ml of water for 15 minutes, standing still for 1 hour, separating the organic layer of chloroform, heating and recovering to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com