Method for preparing galactose chitosan/polyester polymer composite stent

A technology of chitosan and composite scaffolds, which is applied in the field of preparation of scaffolds for liver repair, can solve the problems of difficulty in meeting the application requirements of bioartificial livers, single scaffold components, poor mechanical properties, etc., and achieve good biocompatibility and The effect of biological activity, wide range of material sources and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] (1) Dissolve galactosylated chitosan in distilled water, prepare a galactosylated chitosan solution with a concentration of 0.01g / mL, leave it to defoam; dissolve polycaprolactone in dioxane, Prepare a polymer solution with a concentration of 0.1g / ml;

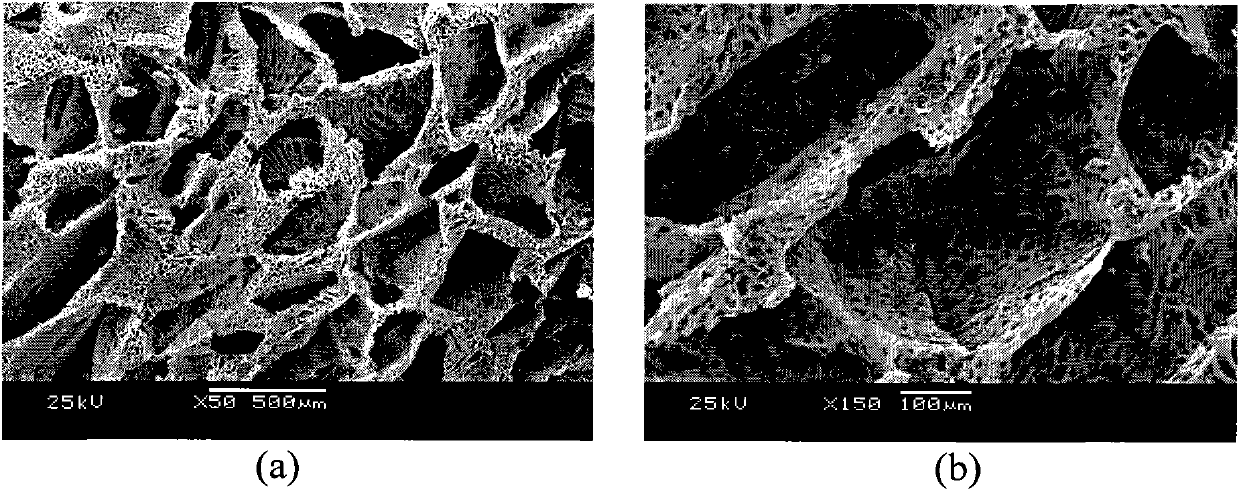

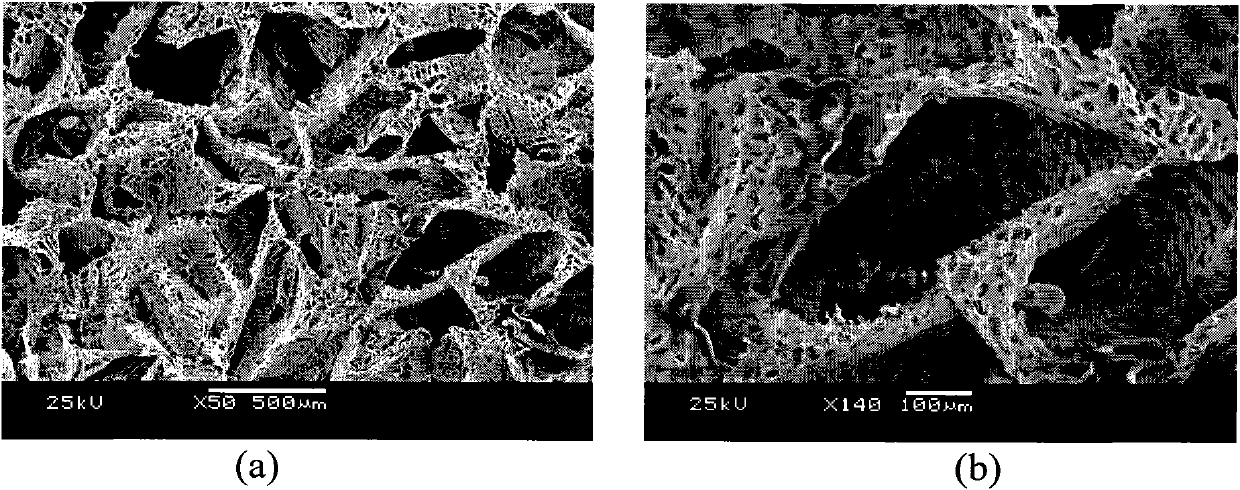

[0027] (2) Pour the 280-450μm gelatin particles sieved with a standard test sieve into the mold, and use a syringe to inject the 85% ethanol solution into the mold to immerse the particles; place the mold in a 70°C oven 5 minutes, make the gelatin particles bond into a template, take out the mold, leave it for a few days until the ethanol is volatilized, freeze-dry; take out the gelatin template, immerse it in the polycaprolactone solution, repeatedly use the method of vacuuming and then returning to normal pressure The polycaprolactone solution is introduced into the template, freeze-dried, and then soaked in 37°C hot water until the gelatin is completely dissolved to obtain the polycaprolactone porous scaffold; figure 1 A...

example 2

[0032] The steps are the same as those in Example 1, but the galactosylated chitosan / polycaprolactone composite scaffold was obtained by reacting in the galactosylated chitosan aqueous solution under stirring at 37°C for 16 hours.

example 3

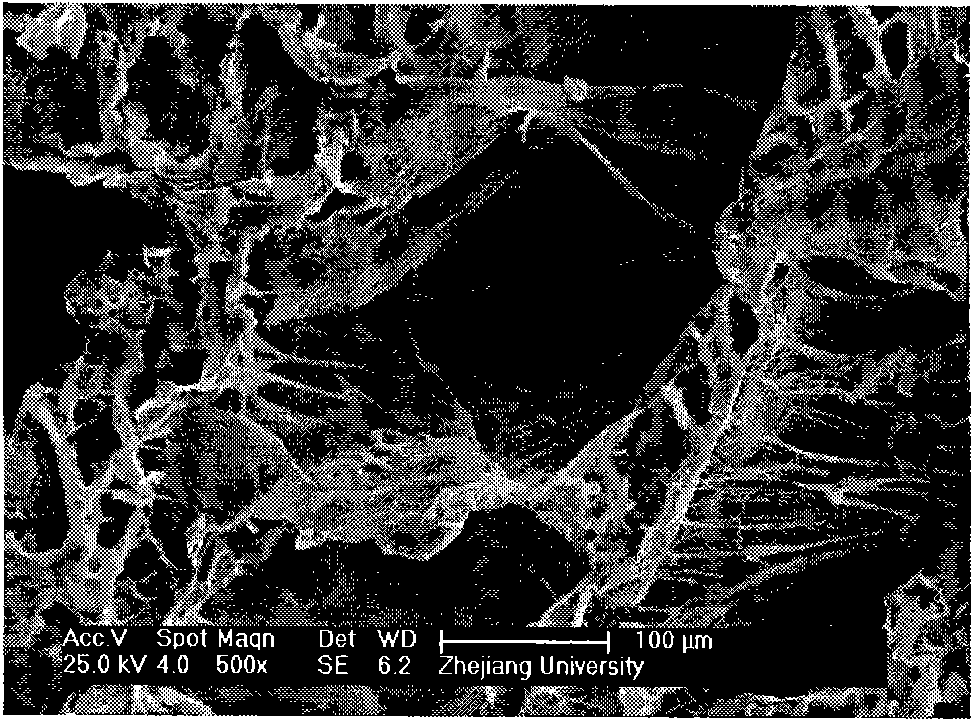

[0034] The steps are the same as those in Example 1, but the dioxane solution of polylactic acid-glycolic acid copolymer is used, and the solution is treated in 0.5mol / L sodium hydroxide solution for 60 minutes, and then in carbodiimide salt Activate for 12 hours in a 1:1 mixed solution of acid salt and N-hydroxysuccinimide by molar ratio, and finally react for 4 hours in an aqueous solution of galactosyl chitosan at 37°C under stirring to obtain galactosyl chitosan. Sugar / polylactic acid-glycolic acid copolymer composite scaffold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com