Preparation method of microwave vacuum puffing pumpkin chips

A technology of microwave vacuum puffing and pumpkin chips, which is applied in the field of food processing, can solve the problems that pumpkin nutrition, health care and medicinal value are difficult to fully reflect, destroy pumpkin nutrition components, and are prone to corruption, etc., so as to avoid the destruction of heat-sensitive components, The effect of short time and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

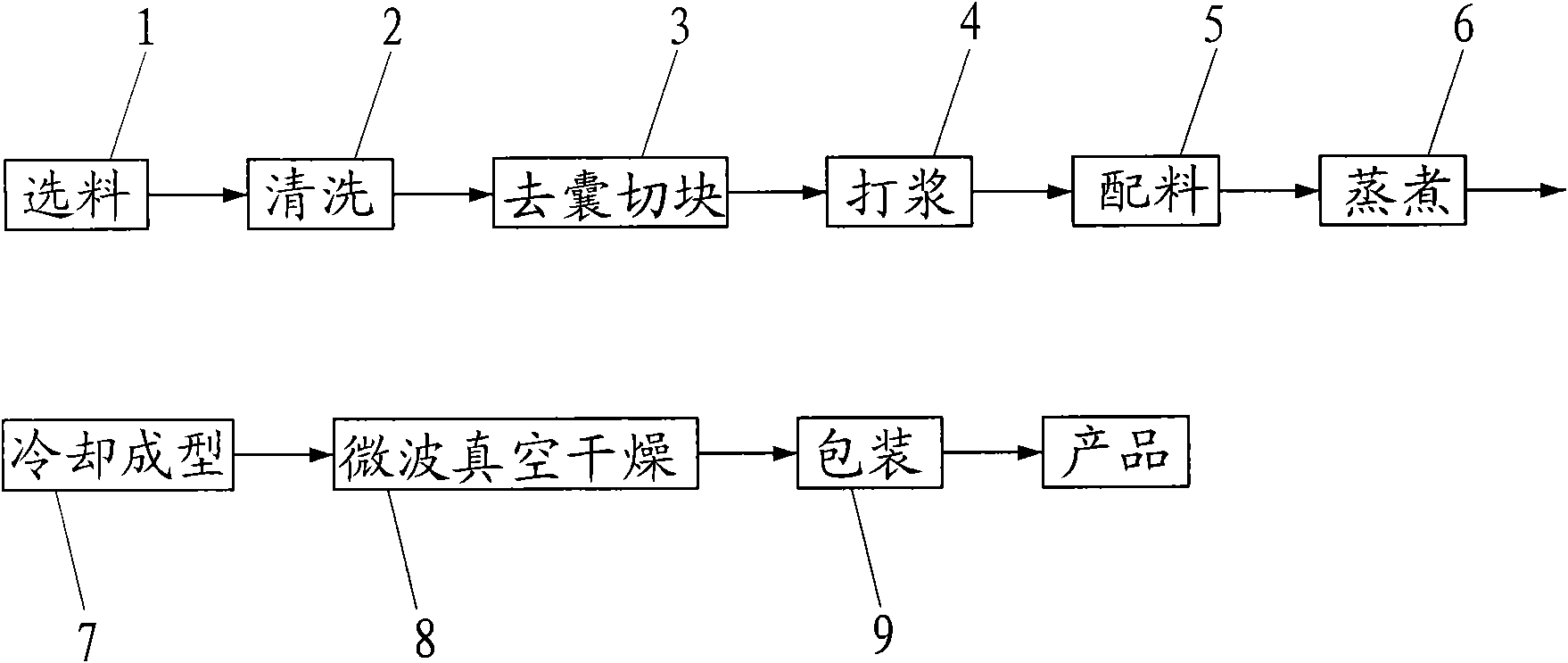

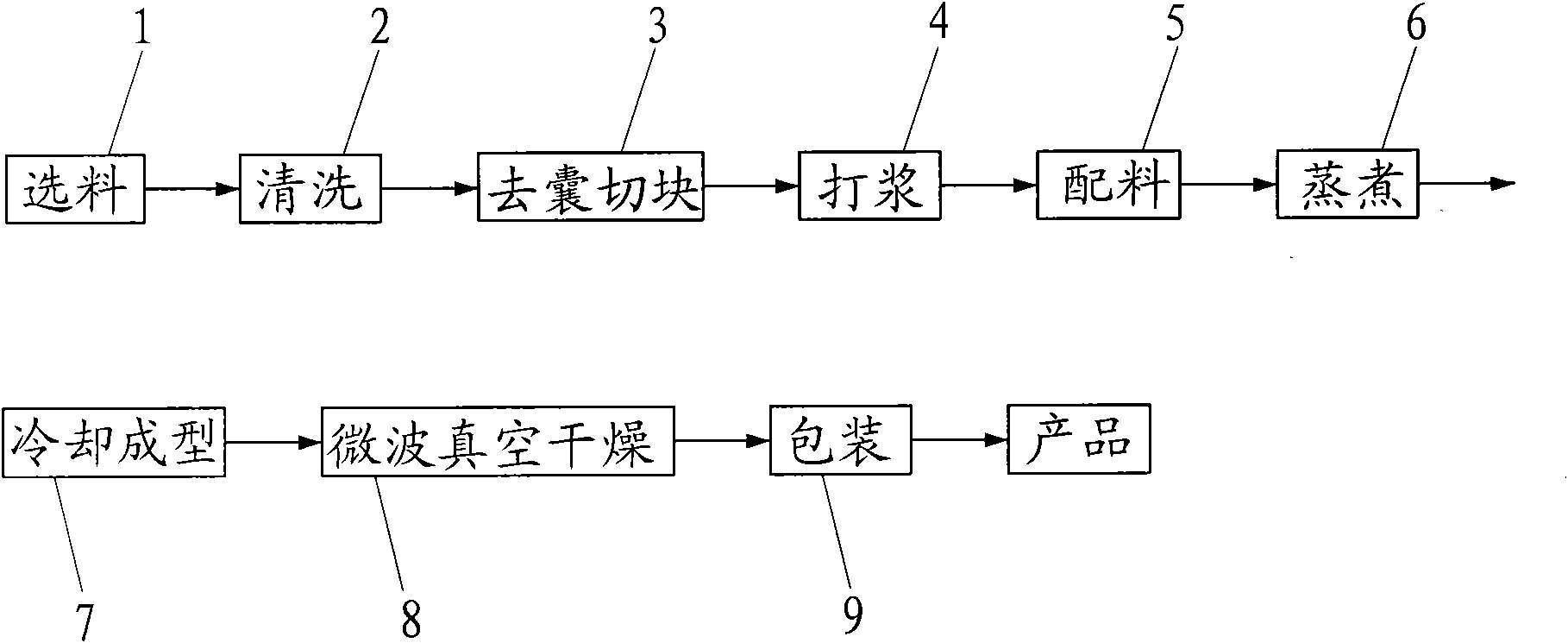

[0023] The present invention is a kind of preparation method of microwave vacuum puffed pumpkin chips, which comprises the following steps:

[0024] (1) Raw materials: Choose 100kg of mature pumpkins with no rot and deterioration, no softening, smooth skin, orange-red flesh, and good flavor; (2) Cleaning: Wash the pumpkin twice with tap water to remove impurities on the surface of the pumpkin . (3) Decapsulation: remove the peduncle of the washed pumpkin, cut it into two halves with a knife, remove the capsule and seeds, and cut into blocks; (4) Beating: add 10 kg of water to the decapsulated pumpkin for beating; (5 ) deployment: add 10kg starch, 25kg flour, 3kg edible vegetable oil, 5kg white sugar and stir evenly to make pumpkin pulp; ) Cooling and forming: the cooked pumpkin slices are cooled to room temperature and pressed into 3cm in diameter and 1.5cm thick discs; (8) Microwave vacuum drying: the formed pumpkin slices are placed in a microwave vacuum dryer and subjected...

Embodiment 2

[0026] Its steps (1)-(3) are identical with embodiment 1, and the steps of change are as follows:

[0027] (4) Beating: Add 25kg of water to the decapsulated pumpkin for beating; (5) Blending: Add 25kg of starch, 15kg of flour, 4kg of cooking oil, and 10kg of sugar and stir evenly to make pumpkin paste; (6) Cooking: Put the pumpkin Put the dough into the steamer and steamer and steam it over water and take it out; (7) Cooling and forming: Cool the cooked pumpkin slices to room temperature and press them into discs with a diameter of 3 cm and a thickness of 1.5 cm; (8) Microwave vacuum drying: Place the formed pumpkin slices in a microwave vacuum dryer for segmental microwave vacuum drying: the first stage of drying, keep the vacuum degree in the drying chamber -50kPa, select the microwave power at 30W / g, control the drying temperature at 80°C, and dry The drying time is within 8 minutes; in the second stage of drying, keep the vacuum degree in the drying room at -30kPa, select...

Embodiment 3

[0029] Its steps (1)-(3) are the same as in Example 1, and the changed steps are as follows: (4) beating: adding 30 kg of water to the pumpkin after decapsulation; (5) blending: adding 35 kg of starch, 10 kg of flour, and 5 kg of edible Stir the oil and 15kg of white sugar evenly to make pumpkin pulp; (6) Cooking: put the pumpkin pulp into the steamer and steam the drawer and steam it out; (7) Cooling and forming: cool the cooked pumpkin slices to Room temperature, pressed into a diameter of 3cm, thick 1.5cm disc; (8) Microwave vacuum drying: put the formed pumpkin slices in a microwave vacuum dryer, and carry out segmented microwave vacuum drying: the first stage of drying, keep the drying room The vacuum degree is -65kPa, the microwave power is 50W / g, the drying temperature is controlled at 85°C, and the drying time is within 8min; the second stage of drying is to keep the vacuum degree in the drying chamber -65kPa, the microwave power is 15W / g, and the drying temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com