High silver supported zeolite molecular sieve acetate deiodinase adsorber and preparation method thereof

A zeolite molecular sieve and adsorbent technology, applied in the field of deiodination zeolite molecular sieve adsorbent and its preparation, can solve the problems of violent molecular movement, poor deiodination effect, loss, etc., and achieve high crystallization degree, high particle strength, and silver loading capacity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

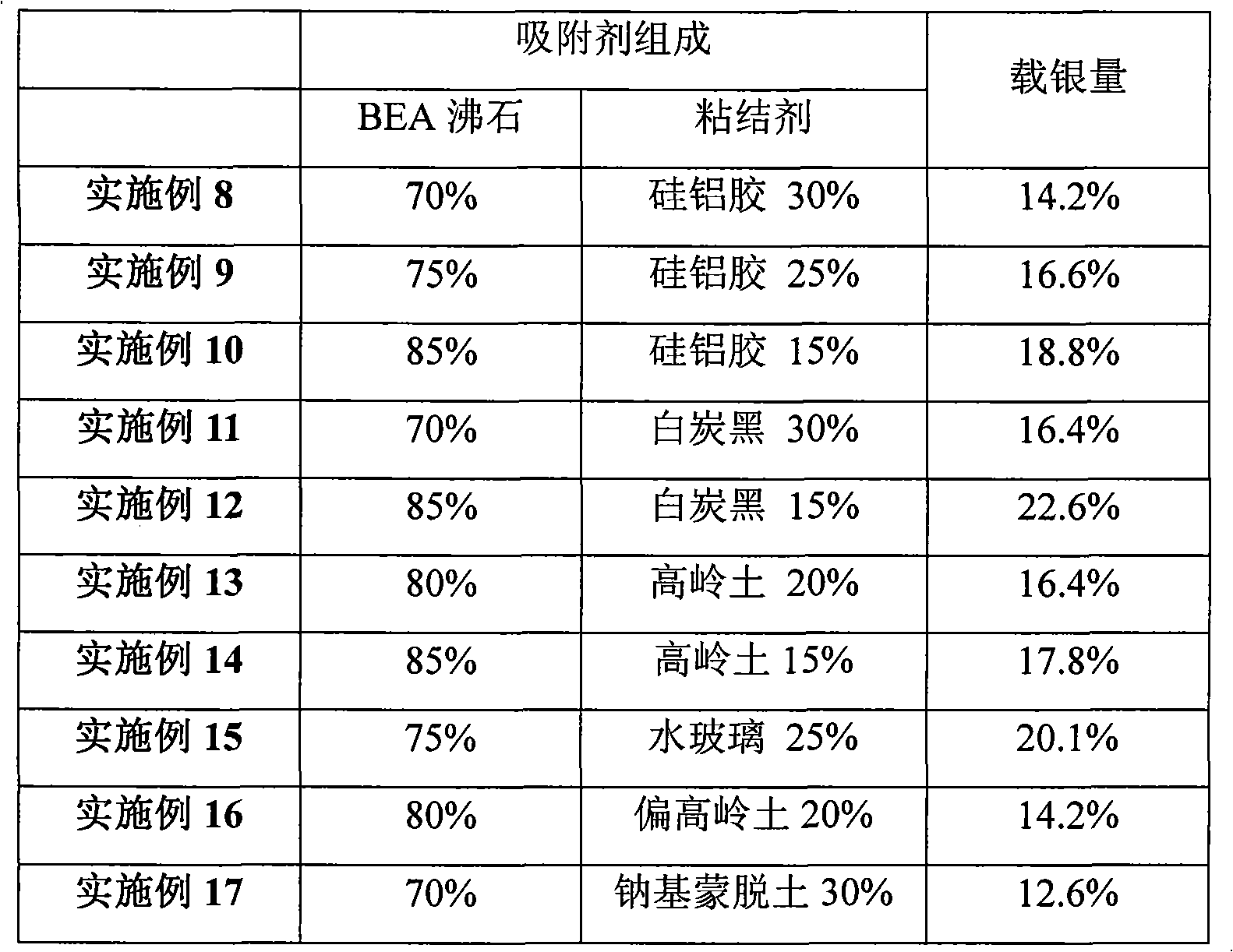

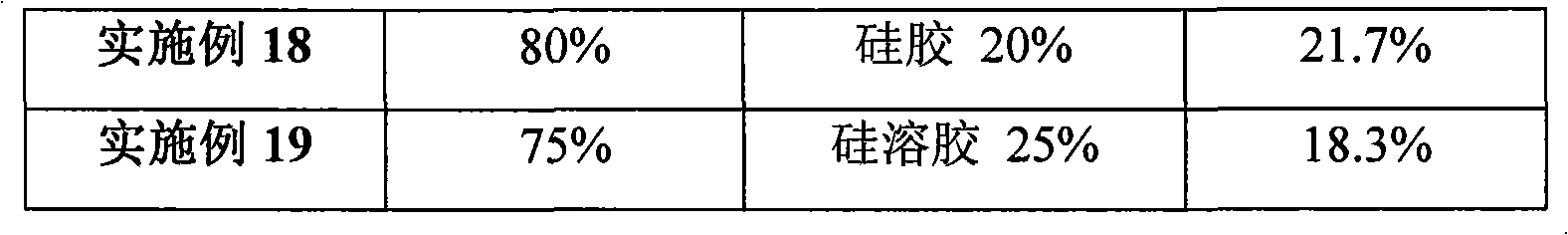

Examples

Embodiment 1

[0029] Commercially available zeolite mineral raw powder is subjected to cation exchange according to the following steps to make H-STI zeolite:

[0030] 1. Add BEA raw powder to 1.5mol / l ammonium chloride solution, the solid-to-liquid ratio is 1:8, heat to 95-105°C and reflux for 4 hours, exchange three times, wash and dry with water.

[0031]2. The BEA powder exchanged with ammonium chloride was roasted at 550° C. for 5 hours to transform into hydrogen zeolite.

[0032] 3. Add the roasted hydrogen-type zeolite to 1 mol / l acetic acid, the solid-to-liquid ratio is 1:6, heat to 90-95°C and reflux for 4 hours, wash and dry to obtain H-BEA for the preparation of deiodination adsorbent pink.

Embodiment 2

[0034] H-BEA powder and binder silica sol (SiO 2 Content 20wt%) mix, make the bead of diameter 1 millimeter in the rolling ball machine. The amount of zeolite in the pellets and the SiO in the binder 2 The mass ratio is 80 / 20. X-ray powder diffraction showed a relative crystallinity of 80%. The pellets are heated in a closed stainless steel reactor for hydrothermal strengthening treatment at a temperature of 180 degrees for 24 hours. After the treatment, the pellets of the substrate adsorbent were obtained, the relative crystallinity increased to 105%, the strength reached 30 Newton / particle, and the specific surface area was 415m 2 / g.

Embodiment 3

[0036] H-BEA powder and binder silica (SiO 2 Content 25wt%) mix, make the bead of diameter 1.5 millimeters in the rolling ball machine. The amount of zeolite in the pellets and the SiO in the binder 2 The mass ratio is 75 / 25. X-ray powder diffraction showed a relative crystallinity of 78%. The pellets are heated in a closed stainless steel reactor for hydrothermal strengthening treatment at a temperature of 160 degrees for 20 hours. After the treatment, the pellets of the base adsorbent were obtained, the relative crystallinity increased to 103%, the strength reached 28 Newton / particle, and the specific surface area was 410m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size of the opening | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com