Preparation method of rutile phase vanadium dioxide nanowire and application

A technology of vanadium dioxide nanometer and rutile phase, which is applied in the direction of vanadium oxide, nanostructure manufacturing, nanotechnology, etc. It can solve the problems that have not yet seen rutile phase vanadium dioxide nanowires, etc., and achieve low production cost, easy control and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Disperse 3.64g of vanadium pentoxide powder in 200g of 0.1M aqueous oxalic acid solution, stir vigorously for 10 minutes, weigh a certain amount of ammonium molybdate and add it to the above solution, the molar ratio of ammonium molybdate to vanadium ions is 4:100 , to obtain an aqueous solution of vanadium ions with a molar concentration of 0.2mol / L, add the above solution into a 250ml hydrothermal kettle with a filling ratio of 80%, raise the temperature to 200°C, keep it warm for 96 hours, synthesize it through hydrothermal reaction, and then put the hydrothermal kettle Take it out, put it into a water bath cooling tank, and cool it quickly so that the cooling rate is 1min. It drops to 60°C within 1min. Then it is naturally cooled to room temperature, centrifuged, washed with deionized water, and dried in an oven at 70°C for 24h. The rutile phase vanadium dioxide nanowires were obtained.

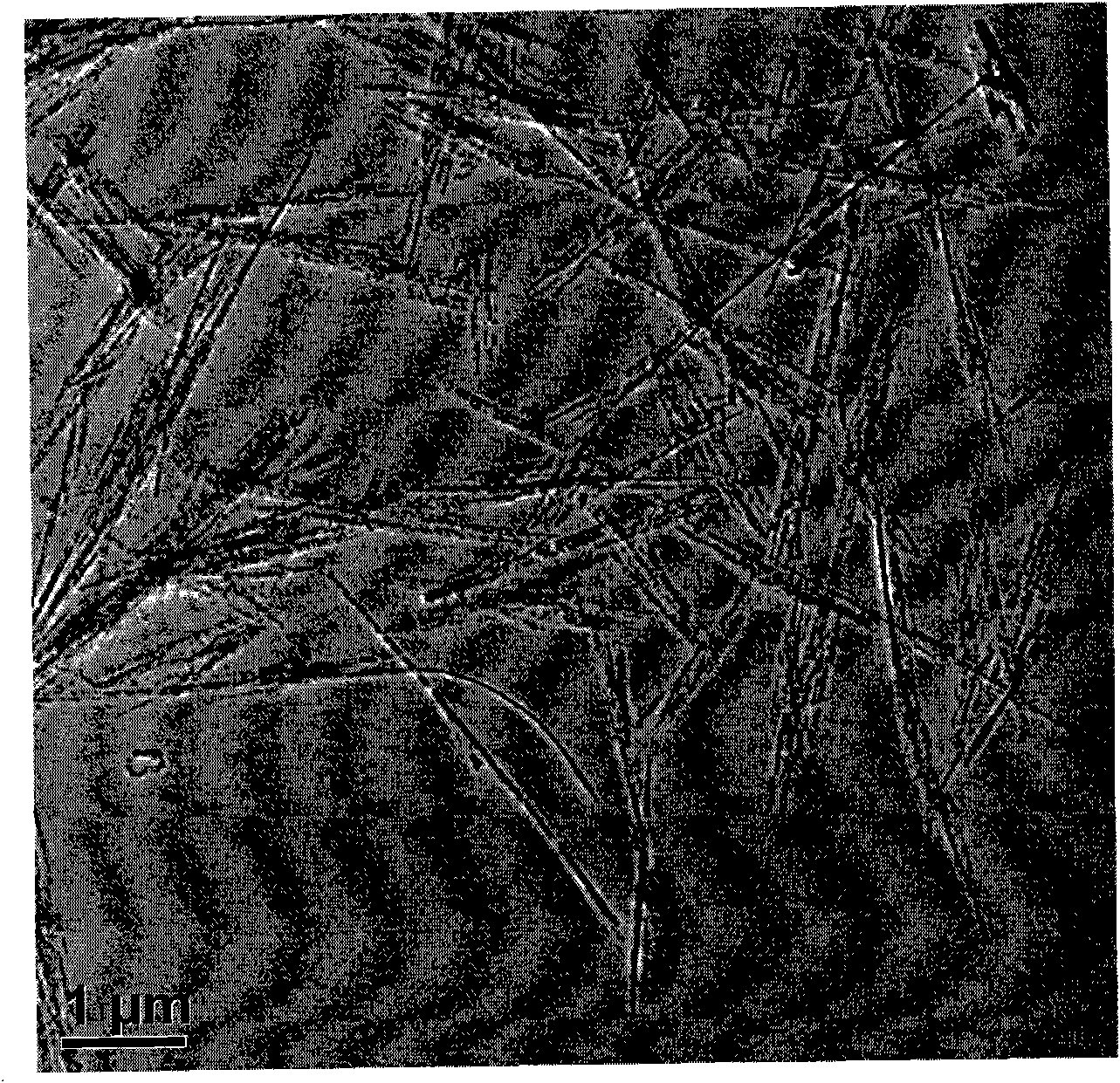

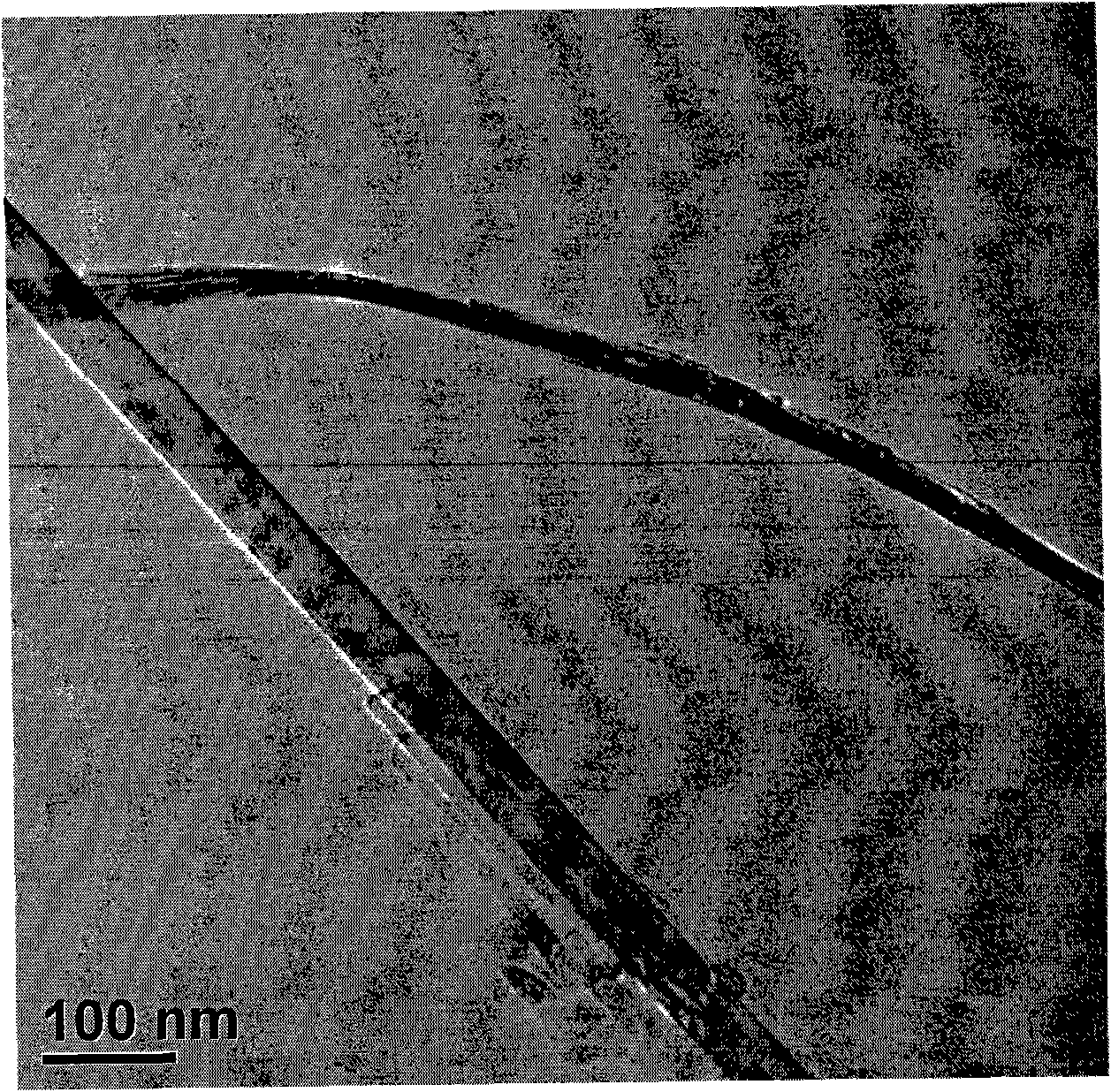

[0039] After testing, get figure 1 with figure 2 , figure 1 The surface ob...

Embodiment 2

[0043] Add 4.5g of oxalic acid (2M) into 180ml of vanadyl dichloride aqueous solution with a concentration of 0.005mol / L, stir vigorously for 10 minutes, weigh a certain amount of sodium tungstate and add it to the above solution, the molar ratio of sodium tungstate to vanadium ions is 2 : 100, to obtain the vanadium ion aqueous solution that the molar concentration is 0.005mol / L, the above-mentioned solution is added in the 250ml hydrothermal kettle, the filling ratio is 72%, is warming up to 280 ℃, is incubated 0 hour, synthesizes through hydrothermal reaction, then water Take out the hot kettle, put it into a water bath cooling tank, and cool it quickly so that the cooling rate drops to 60°C within 1min. Then cool it down to room temperature naturally, then centrifuge it, wash it with deionized water, and dry it in an oven at 70°C After 24 hours, the rutile phase vanadium dioxide nanowires were obtained.

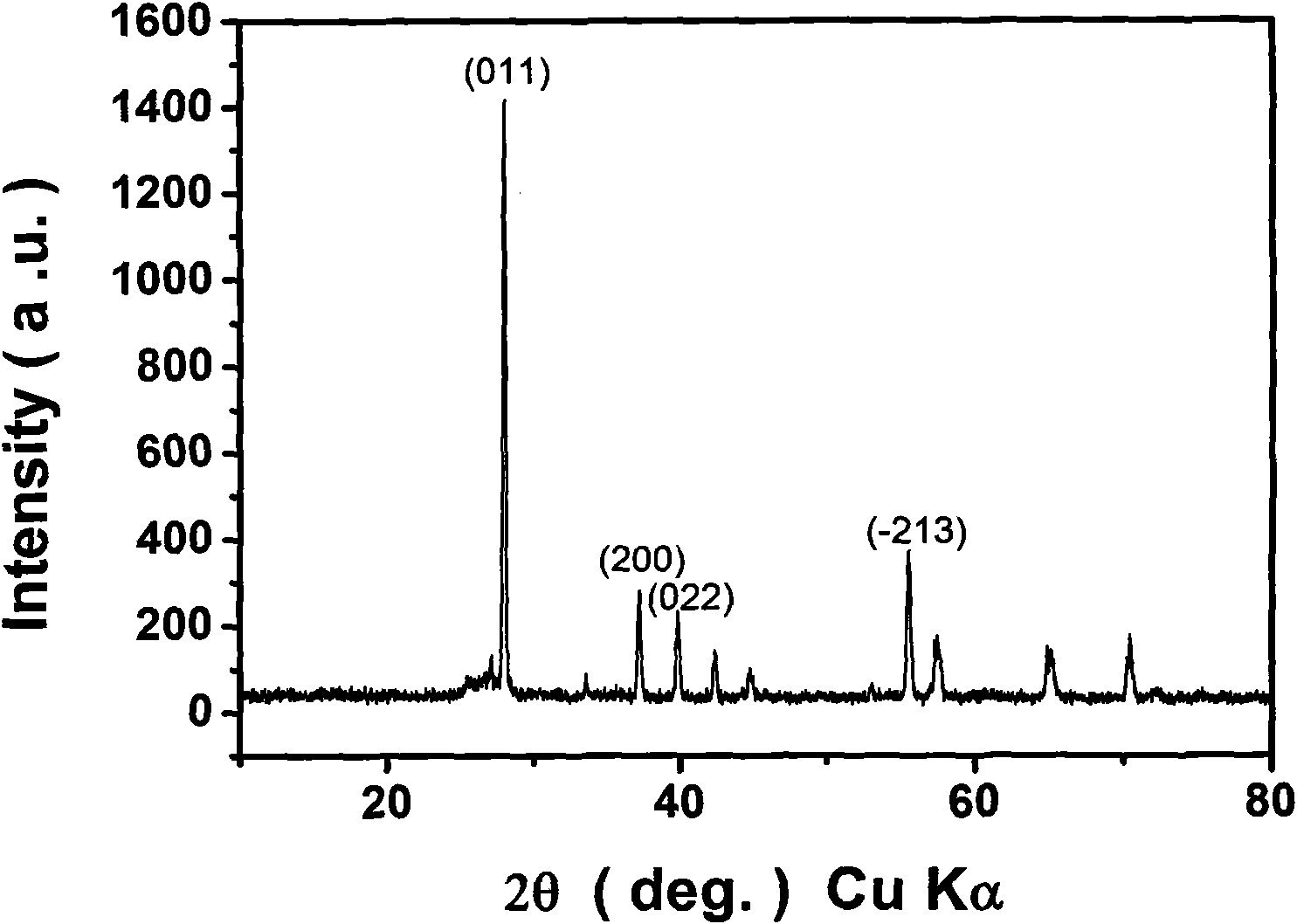

[0044] detected image 3 , image 3 It is the XRD spectrum of the ...

Embodiment 3

[0050] Prepare 150ml of vanadyl oxalate aqueous solution with a molar concentration of 0.1mol / L, stir vigorously for 10 minutes, add the above solution into a 250ml hydrothermal kettle with a filling ratio of 60%, raise the temperature to 350°C, keep it warm for 1 hour, and undergo hydrothermal reaction Synthesize, then take out the hydrothermal kettle, put it into a water bath cooling tank, first cool it rapidly, so that the cooling rate drops to 80°C within 1min., then naturally cool to room temperature, centrifuge, wash with deionized water, and drying in an oven at 70° C. for 24 hours to obtain rutile phase vanadium dioxide nanowires.

[0051] After detection, the obtained rutile phase vanadium dioxide nanowire has a diameter of 30 nm, a length of 10-20 μm, and a phase transition temperature of 70° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com