Method for treating industrial sewage of automobile making

A technology for automobile manufacturing and industrial wastewater, applied in separation methods, sustainable biological treatment, chemical equipment and methods, etc. rate, long-generation reproduction cycle, and the effect of improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

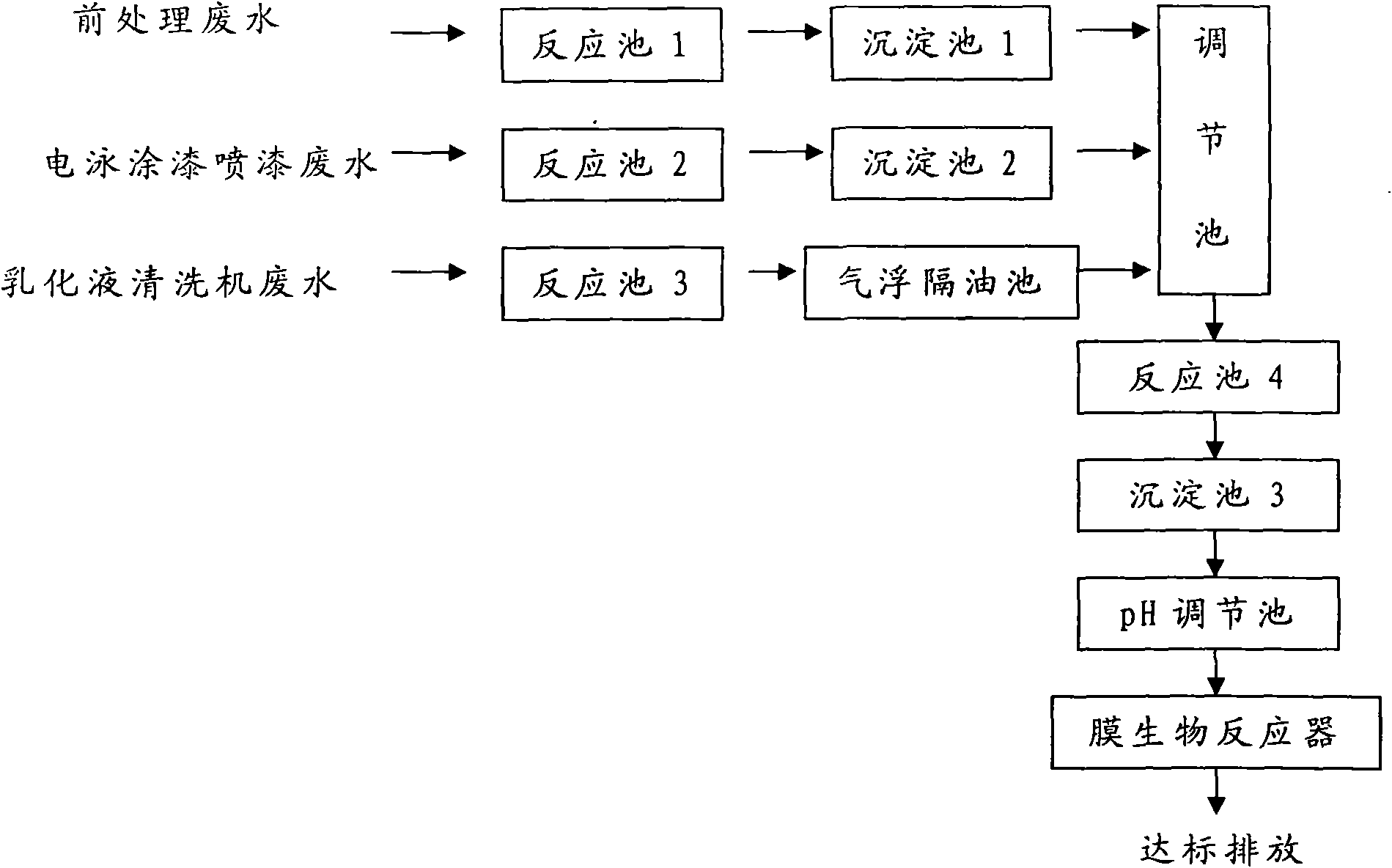

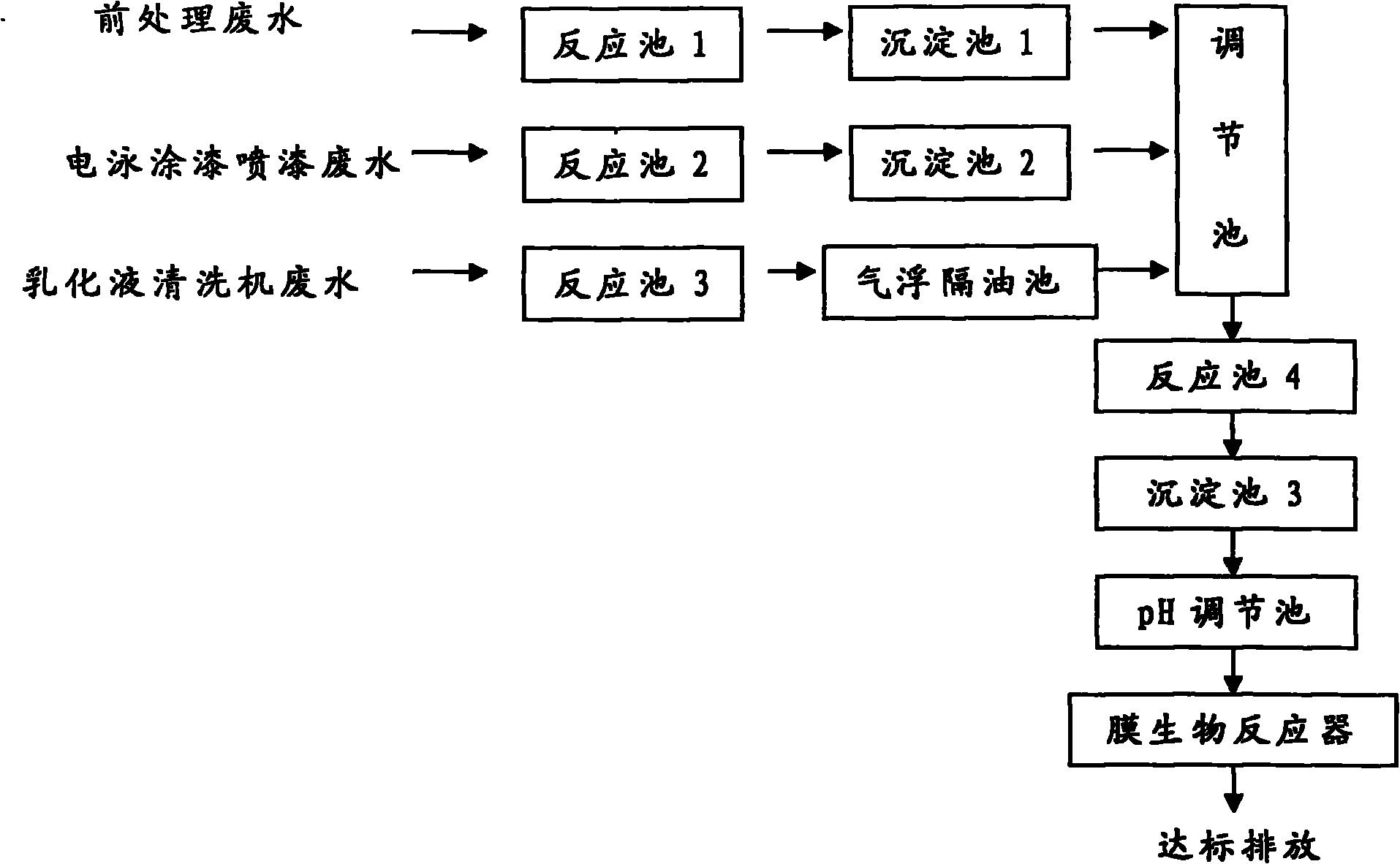

[0009] The automobile manufacturing industry wastewater treatment method of the present invention comprises: the physical and chemical pretreatment method of pretreatment wastewater, electrophoretic paint spray wastewater, emulsion cleaning machine wastewater, the pretreatment method before the wastewater from the adjustment pool enters the biochemical system, and the biochemical treatment method. . Its basic technological process is as follows:

[0010] The primary physical and chemical treatment of the pre-treatment wastewater is carried out through the reaction tank 1 and the sedimentation tank 1 to remove large suspended particles and phosphate in the wastewater, and the chemical agents are lime, polyaluminum chloride and polyacrylamide.

[0011] Through the reaction tank 2 and the sedimentation tank 2, the electrophoretic painting wastewater is subjected to acid analysis and coagulation sedimentation treatment to remove the polymer resin, pigment, titanium dioxide and ani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com