Preparation method of fluorine-containing MFI zeolite membrane

A zeolite molecular sieve membrane and zeolite molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of inability to form a dense molecular sieve layer, long synthesis time, high preparation cost, etc., to reduce the content of silicon source and template agent, Save preparation steps and time, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

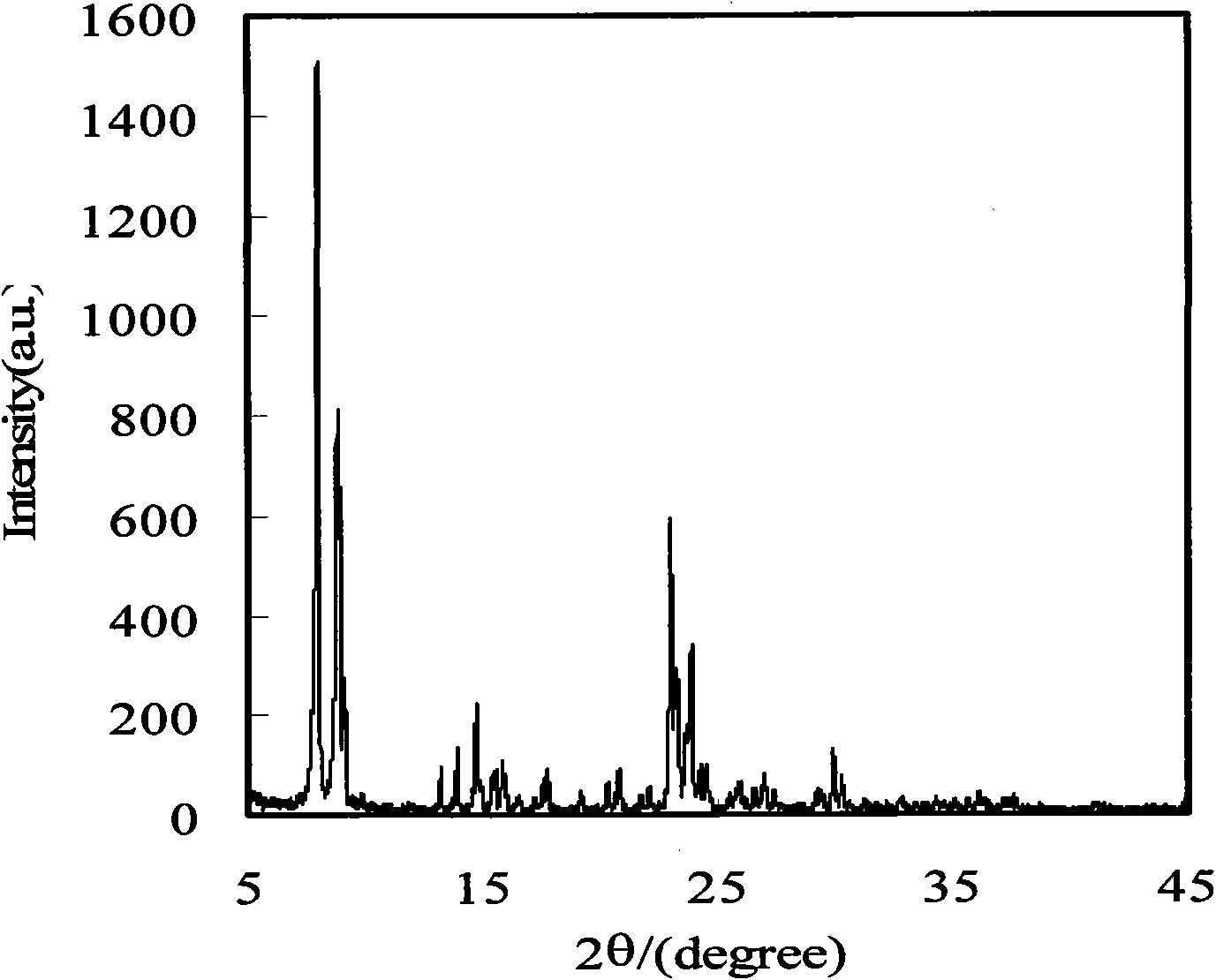

[0043] Example 1: Preparation of fluorine-containing MFI zeolite molecular sieve seed crystals

[0044] Mix the template agent tetrapropylammonium hydroxide, sodium hydroxide, silica sol, sodium fluoride and appropriate amount of water evenly, and mix and stir at room temperature to form a stable sol, stir and age for 24 hours, the formed SiO 2 -Na 2 O-TPAOH-MF-H 2 The molar ratio of each component in the O sol system is: MF / SiO 2 =0.15, NaOH / SiO 2 = 0.25, TPAOH / SiO 2 =0.3,H 2 O / SiO 2 =20; the above-mentioned aged sol was put into a polytetrafluoroethylene-lined stainless steel reactor, and then the reactor was placed in an oven preheated to 120°C for crystallization for 30 hours. After the reaction was completed, the reaction solution had obvious stratification. The reaction product was centrifuged, washed to neutral, dried, and put into a muffle furnace at 550°C for 6 hours to remove the template agent to obtain the fluorine-containing all-silicon MFI zeolite molecula...

Embodiment 2

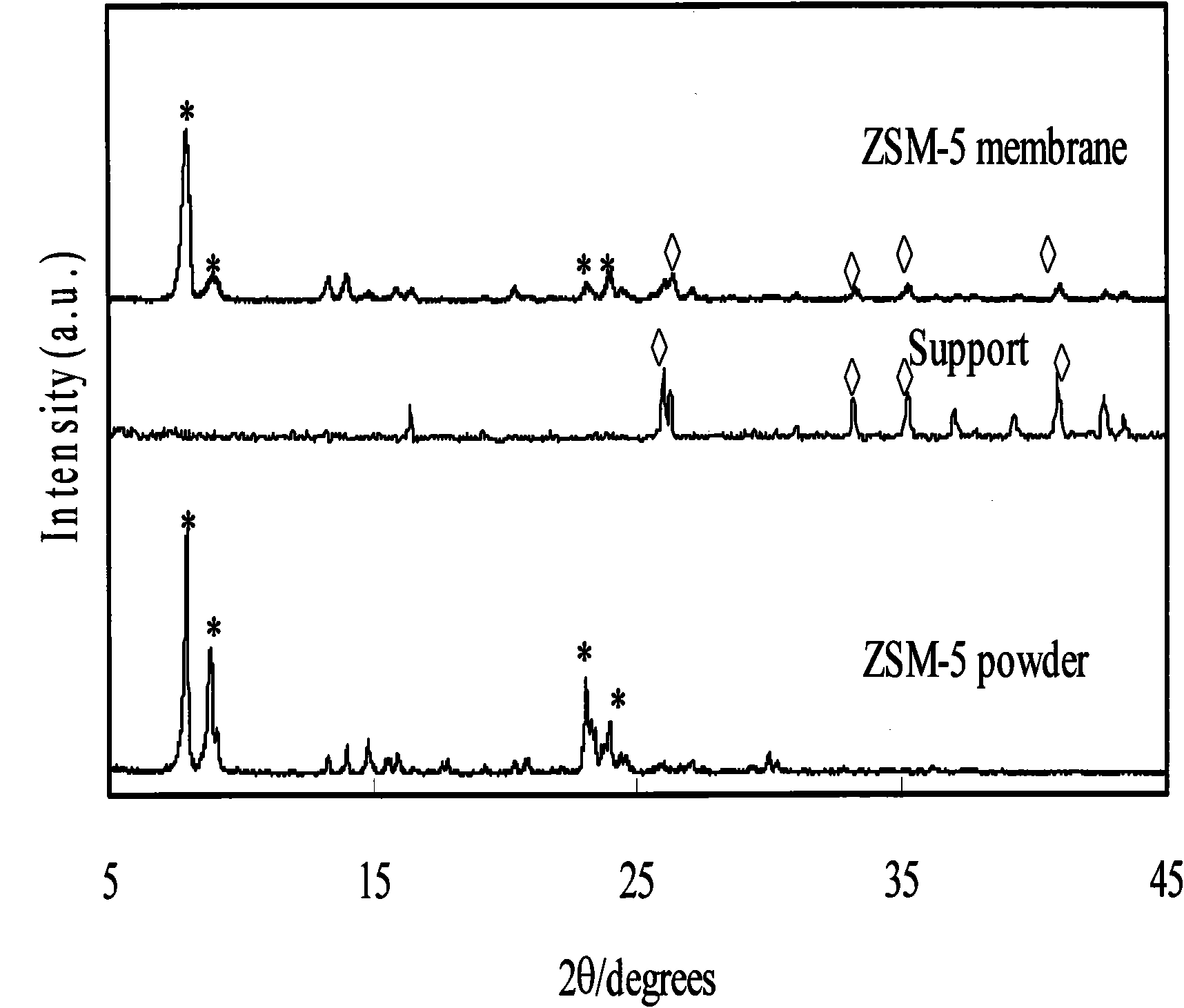

[0046] Example 2: Preparation of fluorine-containing MFI zeolite molecular sieve membrane

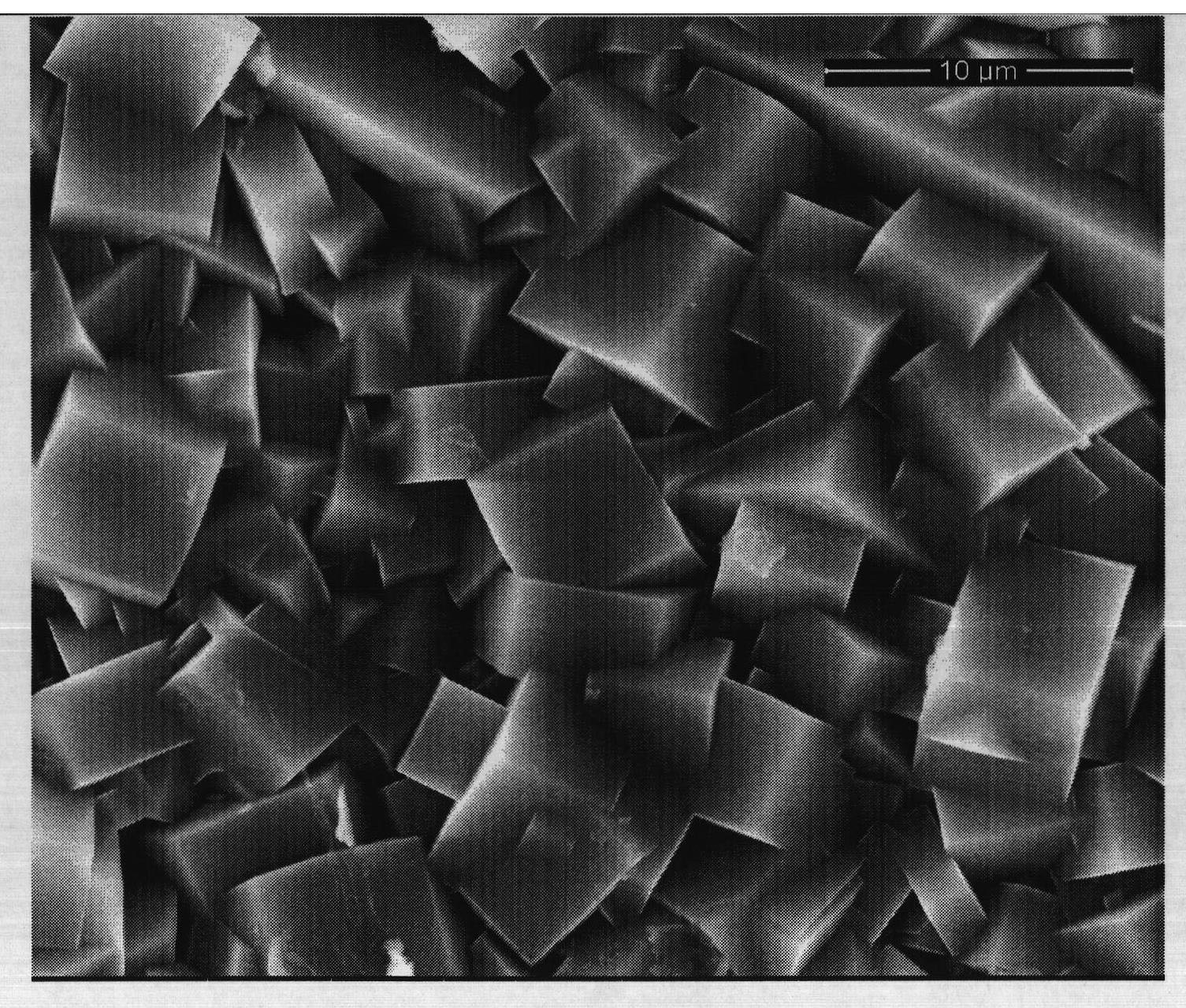

[0047] The porous carrier is tubular mullite produced by Japan Nikkato Co., Ltd. (the composition is 67wt.%Al 2 o 3 , 33wt.% SiO 2 ) carrier, the inner and outer diameters are 9 mm and 12 mm respectively, the length is 100 mm, the average pore diameter is about 1 μm, and the porosity is about 43%. After the carrier was smoothed by 1000-mesh sandpaper, it was cleaned by ultrasonic waves in deionized water, and then dried for future use. Then the support is soaked in the methanol solution containing 20wt% dimethyldiethoxysilane, soaked for 20 minutes, the surface of the support is positively charged, and the 5% fluorine-containing MFI zeolite molecular sieve seed crystal (as in Example 1) NaOH solution was added dropwise into the solution to adjust the pH value to 9-10, so that the surface of the seed crystal was negatively charged, and the positively charged support was placed in the ...

Embodiment 3

[0054] Example 3: Preparation of fluorine-containing MFI zeolite molecular sieve membrane

[0055] The synthetic liquid raw material and operating steps that adopt are the same as embodiment 2, and the difference is that the molar proportion of synthetic raw material liquid is F- / SiO 2 =0.5, TPABr / SiO 2 = 0.1, TPAOH / SiO 2 =0.2,H 2 O / SiO 2 =1000, crystallized in an oven at 170°C for 36 hours. The synthesized molecular sieve membrane was confirmed to be MFI zeolite molecular sieve membrane by XRD. Synthetic crystals using 19 Characterization of F and SiF by solid-state NMR technology x 4-x The form exists, that is, F completely enters the crystal skeleton, and the results of plasma emission spectroscopy and F electrode characterization show that the F / Si molar ratio in the crystal is 0.0085.

[0056] The prepared molecular sieve membranes S-3 and S-4 were used for pervaporation characterization in the ethanol / water (5 / 95wt%) system at 60°C, and the results are shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com