Method for preparing biomass-based methanol

A biomass-based methanol technology, applied in the chemical industry, can solve the problems of not reaching the level of industrial production, low methanol yield and selectivity, low sulfur content, etc., achieving high yield and selectivity, and mild reaction conditions. , the effect of rich resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Biomass carbon powder is used to adjust crude bio-oil reintegration into gas under the action of catalyst.

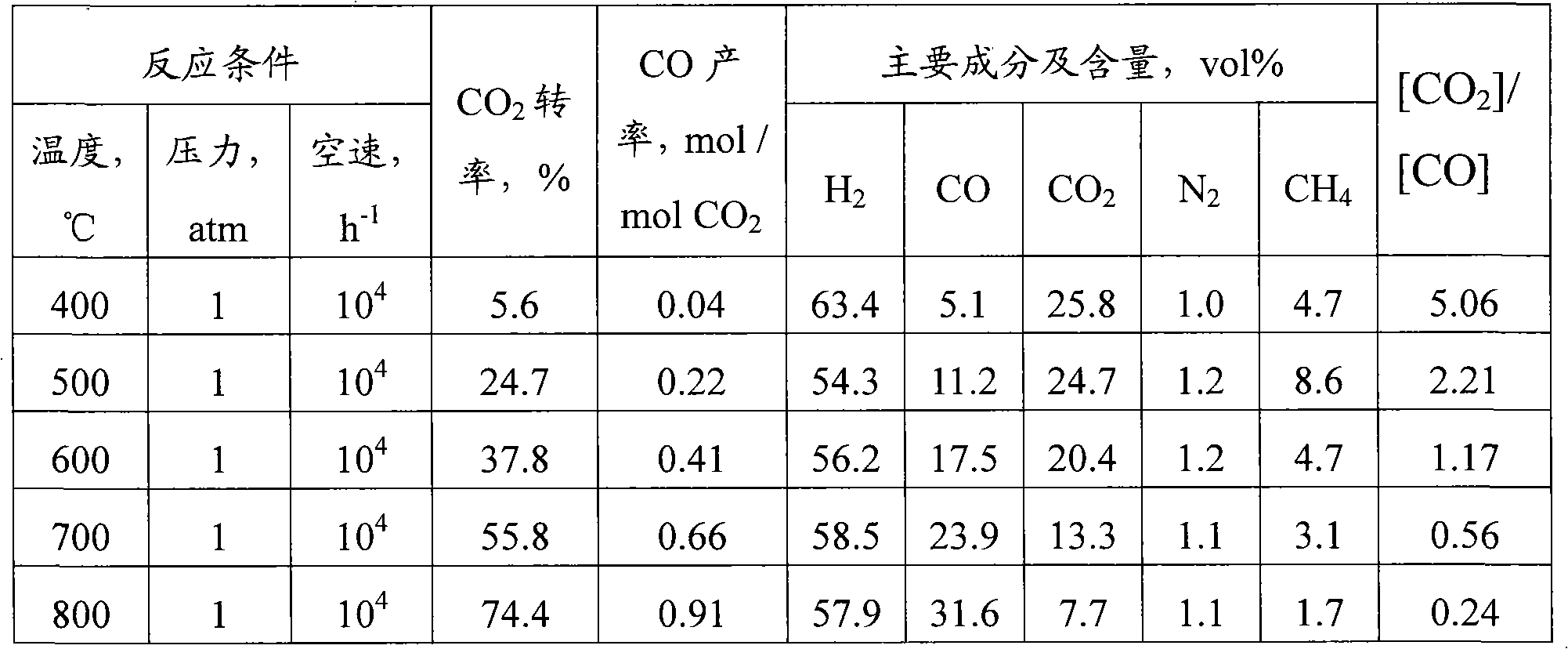

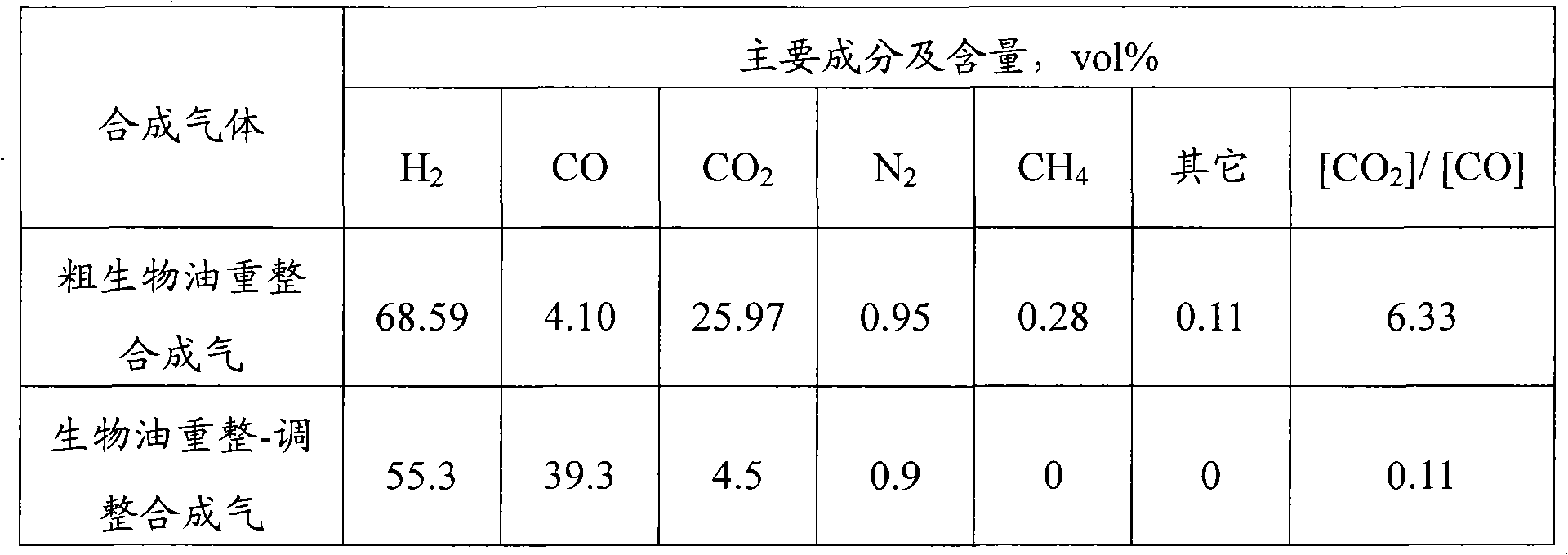

[0041] Using sawdust powder as raw material, crude bio-oil is re-integrated into gas and prepared using a series fluidized bed device system (patent: CN200910116098.6): under the condition of water vapor atmosphere, sawdust powder is cracked into biomass cracking fluidized bed Oil steam, and then the bio-oil steam enters the organic steam reforming fluidized bed after gas-solid separation for steam reforming reaction, reforming the organic matter in the bio-oil steam into crude bio-oil and reintegrating into gas, which is made of wood powder The main components and contents of the crude bio-oil reintegrated gas produced from raw materials are shown in Table 1, which is characterized by hydrogen-rich and carbon dioxide-rich synthesis gas (H 2 / CO=16.73,CO 2 / CO=6.33). In addition, biomass charcoal powder is a by-product in the process of biomass cracking to gene...

Embodiment 2

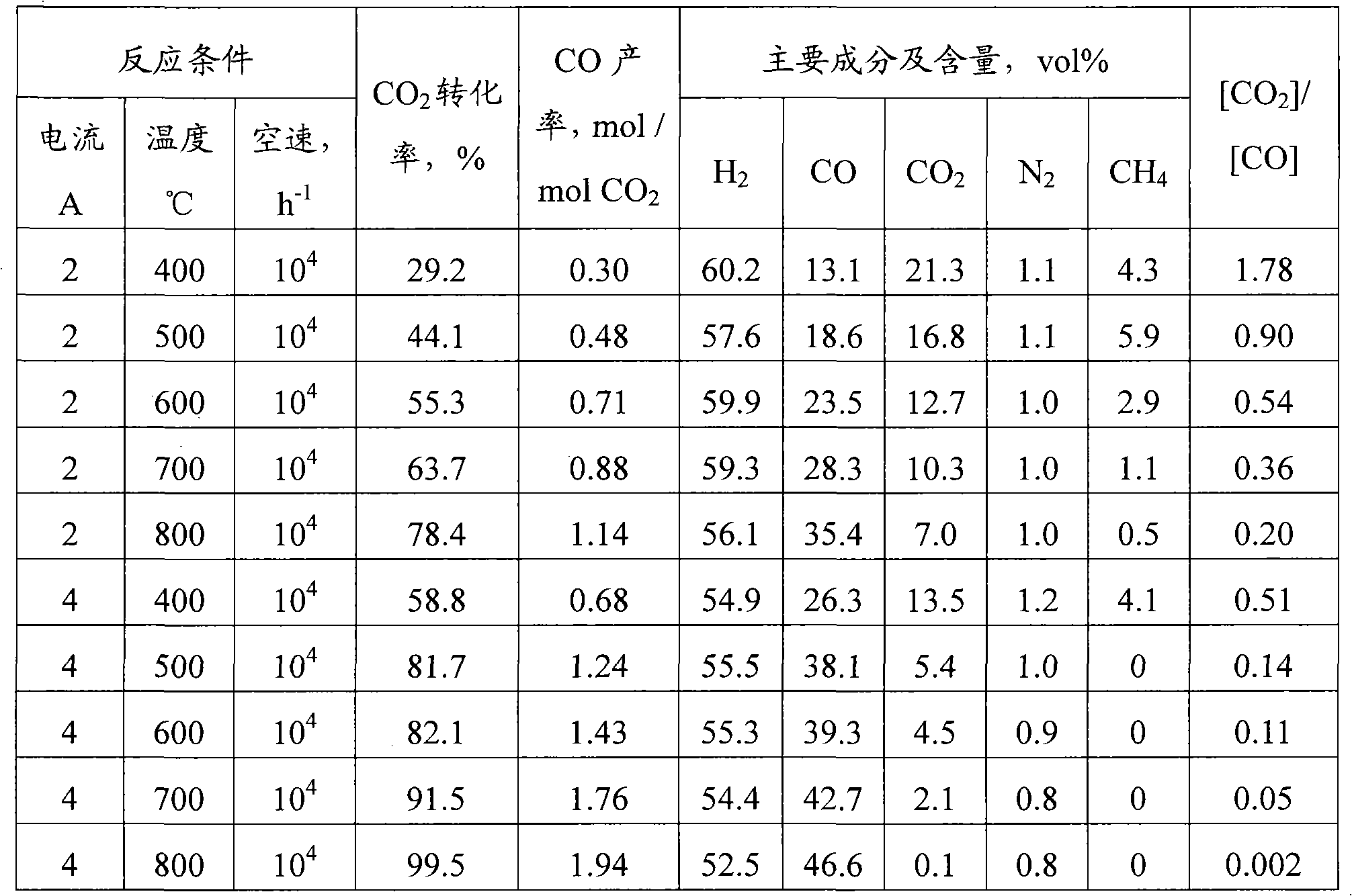

[0050] Biomass carbon powder is used to adjust crude bio-oil reintegration into gas under the action of catalyst and electric current.

[0051] In this embodiment, sawdust powder is used as the raw material, and the crude bio-oil re-integrated into gas, biomass charcoal powder and catalyst are the same as those in Embodiment 1. The reaction device is an electrocatalytic reforming reactor (patent: CN200710134707.1): it includes a cylindrical reforming reactor with an insulating layer (inner diameter: Φ30mm, length: 50cm) and reactants connected at both ends ( Bio-oil recombination into gas) inlet pipeline and reformed tail gas output pipeline, and are respectively provided with control valves and reactant flow controllers, and an external heating device for preheating is provided on the outer wall of the inlet pipeline; It is connected with a tail gas collection system including a water vapor condenser and a dryer; an electric furnace wire with a ceramic insulating layer connec...

Embodiment 3

[0057] Using bio-oil reforming-adjusting synthesis gas to produce biomass-based methanol.

[0058] In the process of this example, the crude bio-oil reintegration into gas adopts a series fluidized bed device system (patent: CN200910116098.6), and under the condition of water vapor atmosphere, the biomass is first cracked into biological Oil vapor, and then in the post-stage fluidized bed reactor, the organic matter in the bio-oil vapor is reformed into hydrogen and carbon dioxide, and the main components and contents of the crude bio-oil re-integrated into gas produced by using wood powder as raw material are shown in Table 4 As shown, it is characterized by hydrogen-rich and carbon dioxide-rich syngas (H 2 / CO=16.73,CO 2 / CO=6.33). In the process of this example, the reintegration of crude bio-oil into gas is adjusted, and 18% NiO-Al with a mass ratio of 1:1 is used in the adjustment process 2 o 3 And HZSM-5 (Si:Al=25) mixed catalyst, biomass charcoal powder, bio-oil re-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com