Preparation methods of multi-element metal chalcogen compound, target and coating material

A technology of chalcogen elements and multi-element metals, which is applied in the coating process of metal materials, non-metallic elements, chemical instruments and methods, etc., can solve problems such as incompatibilities, reaction conditions that cannot be mass-produced, and are not suitable for mass production. The effect of uniform distribution, improved yield rate and reduced production equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

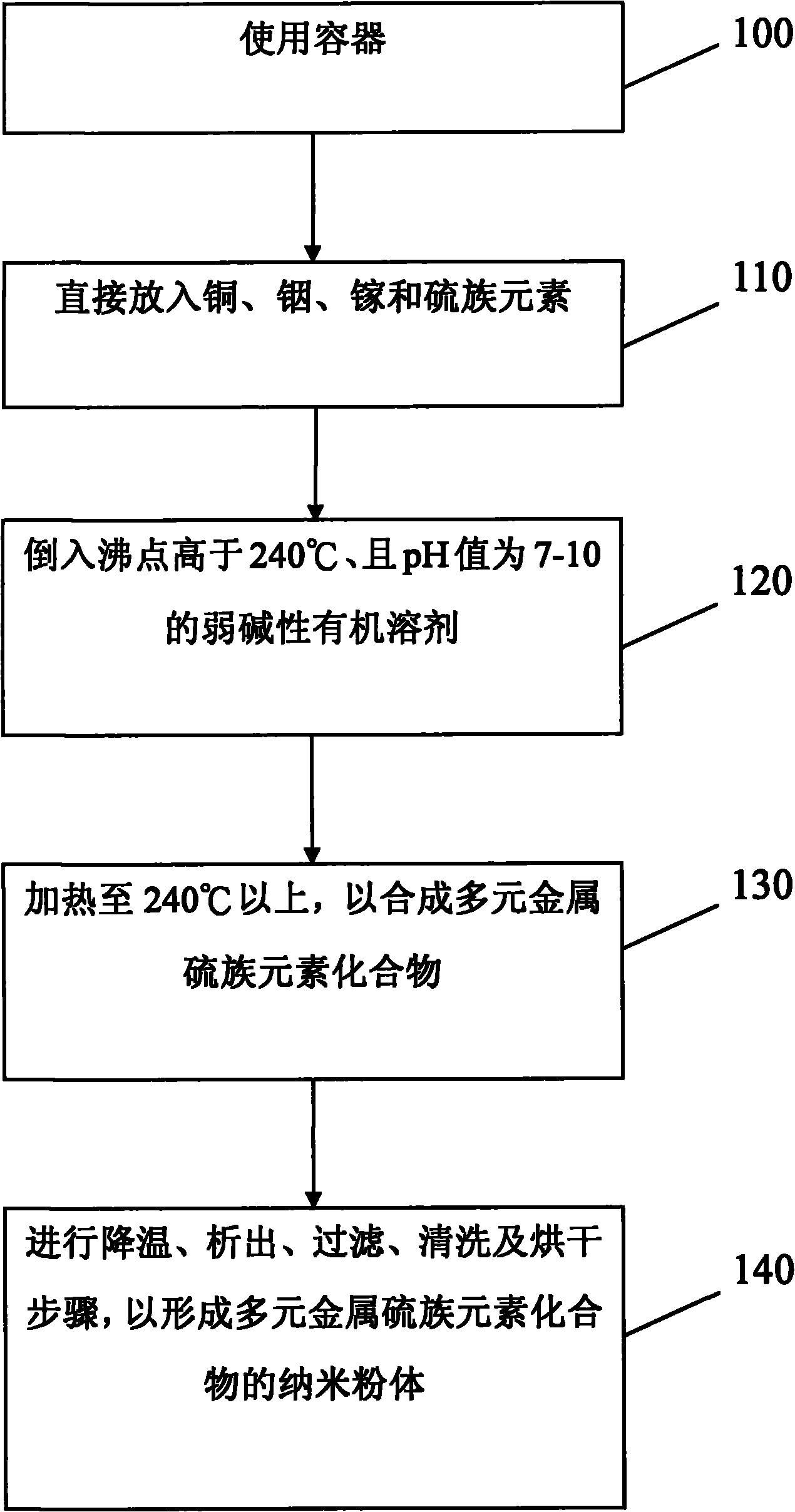

[0036] figure 1 It is a flowchart of a preparation method of a polynary metal chalcogenide compound (Chalcogenide) provided by the present invention. The preparation method includes the following steps: In step 100, at least one container is used. In step 110, at least one of copper element, indium element and gallium element (for example, copper Cu, indium In, gallium Ga, copper Cu and indium In, copper Cu and gallium Ga, indium In and gallium Ga, or a combination of copper Cu and indium In and gallium Ga) and chalcogen elements (for example, sulfur S, selenium Se or tellurium Te) are placed in the container; the copper element, the indium element, and the gallium element are used elemental state simple substances as a starting material. In step 120, at least one weakly basic organic solvent with a boiling point higher than 240° C. and a pH value of 7-10 is provided, and the organic solvent is poured into the above container as a reaction solvent. Alternatively, at least o...

Embodiment 1

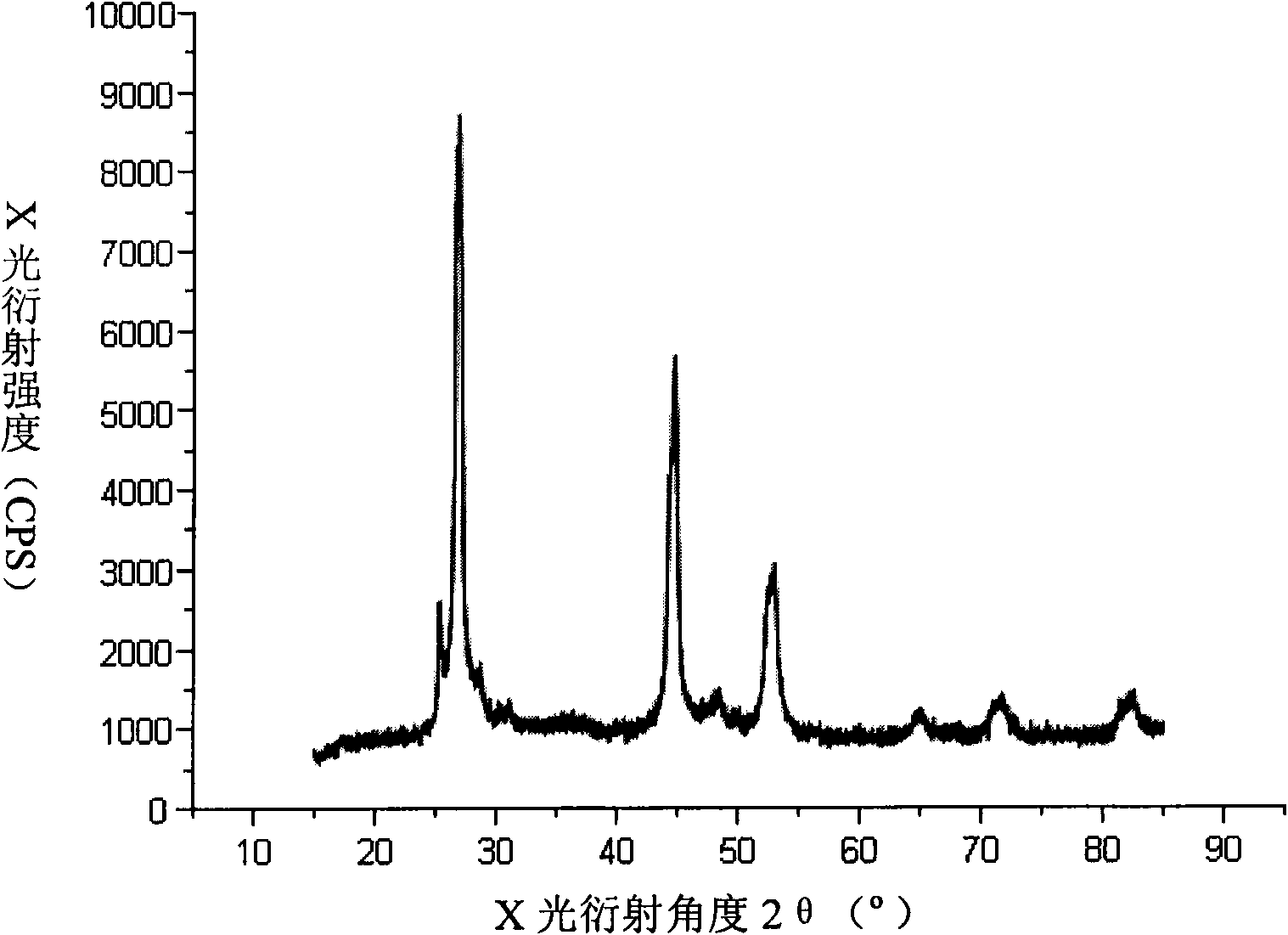

[0048] Heat a 500ml container (for example, a three-necked flask) to 100°C or above, blow in nitrogen, and remove water and oxygen for 1 hour. Then heat the gallium ingot to 30°C, and place about 0.06 mole of gallium, 0.2 mole of copper powder, 0.14 mole of indium powder and 0.5 mole of selenium powder in the above container, and mix with 1.0 mole of diphenylamine (organic solvent) in the container Mix, dissolve, and stir with a magnet for 1 hour, slowly heat to 240 ° C, after the temperature stabilizes, react for 24 hours, then cool down to 80 ° C or below, add a non-solvent (non-solvent) from which water has been removed (such as , methanol or toluene) 300ml, the black solid was precipitated, filtered, and then washed with a non-solvent (such as methanol or toluene), and the obtained solid was dried under vacuum at 50°C or above for 1 hour , and remove it. The non-solvent refers to a solvent that is miscible with the reaction organic solvent (eg, diphenylamine and p-phenyle...

Embodiment 2

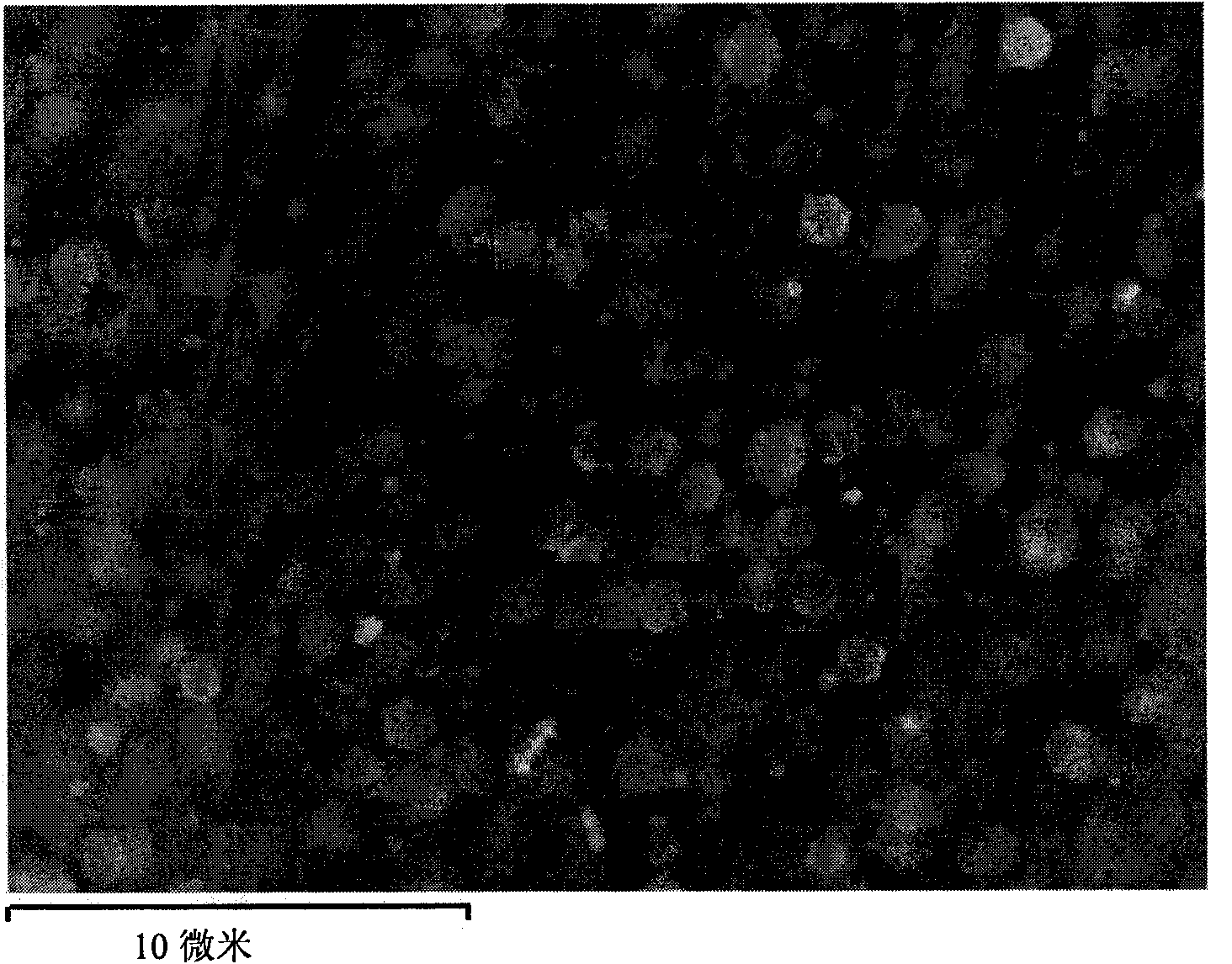

[0051] Heat a 500ml container (for example, a three-necked flask) to 100°C or above, pass in an inert gas (for example, nitrogen, helium or argon), and remove water and oxygen for 1 hour. Then the gallium ingot is heated to 30°C, and about 0.04 moles of gallium, 0.18 moles of copper powder, 0.16 moles of indium powder and 0.44 moles of selenium powder are placed in the above container, and mixed with 0.6 moles of m-phenylenediamine (organic solvent) Mix and dissolve in a container, stir with a magnet for 1 hour, slowly heat to 260°C, wait for the temperature to stabilize, let it stand and react for 24 hours, then cool down to 80°C or below, add 100ml of methanol from which water has been removed, and then take out 20ml The black solution is dripped on a glass sheet, dried into a film, and scanned with an electron microscope (hereinafter referred to as SEM), and the scanning electron microscope photo is as follows: image 3 Shown, then, add 160ml non-solvent (non-solvent) (for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com