Robust controller of permanent magnet synchronous motor based on fuzzy-neural network generalized inverse and construction method thereof

A technology of fuzzy neural network and permanent magnet synchronous motor, applied in motor generator control, electronically commutated motor control, single motor speed/torque control, etc., can solve neural network over-learning and the choice of structure and type depends on experience , limited load capacity, system robustness reduction and other issues, to achieve the effect of high load disturbance resistance and adaptability, strong robustness and fault tolerance, and strong fuzzy reasoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

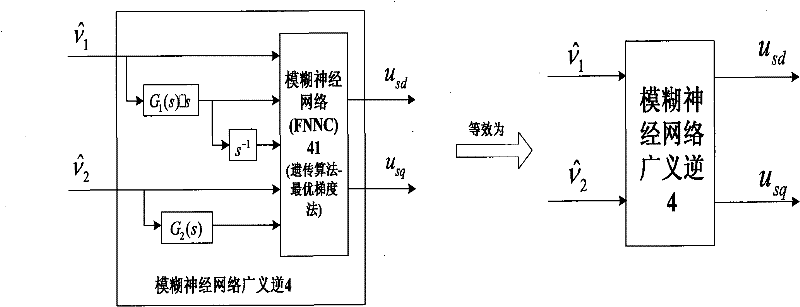

[0022] Such as Figure 5As shown, the fuzzy neural network generalized inverse robust controller 7 of the present invention controls the compound controlled object 3 . The fuzzy neural network generalized inverse robust controller 7 is composed of the internal model controller 6 and the fuzzy neural network generalized inverse 4. The internal model controller 6 is composed of a speed internal model controller 61 and a current internal model controller 62 connected in parallel, wherein the speed internal model controller 61 is composed of a speed internal model 611 and a speed controller 612; the current internal model controller 62 is composed of The current internal model 621 and the current controller 622 are connected. At the same time, the fuzzy neural network generalized inverse 4 in the fuzzy neural network generalized inverse robust controller 7 is connected in series with the compound controlled object 3 to form a generalized pseudolinear system 5, which decouples the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com