Method for synthesizing superparamagnetic ferroferric oxide nano particle in situ by induction of acrylic acid polymer nano hydrogel

A nano-hydrogel, ferric tetroxide technology, applied in the direction of ferric oxide/ferric hydroxide, ferrous oxide, etc., can solve the problems of harsh reaction conditions, weak interaction force, low stability, etc. The effect of simple process, high activity and simple and easy-to-obtain equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

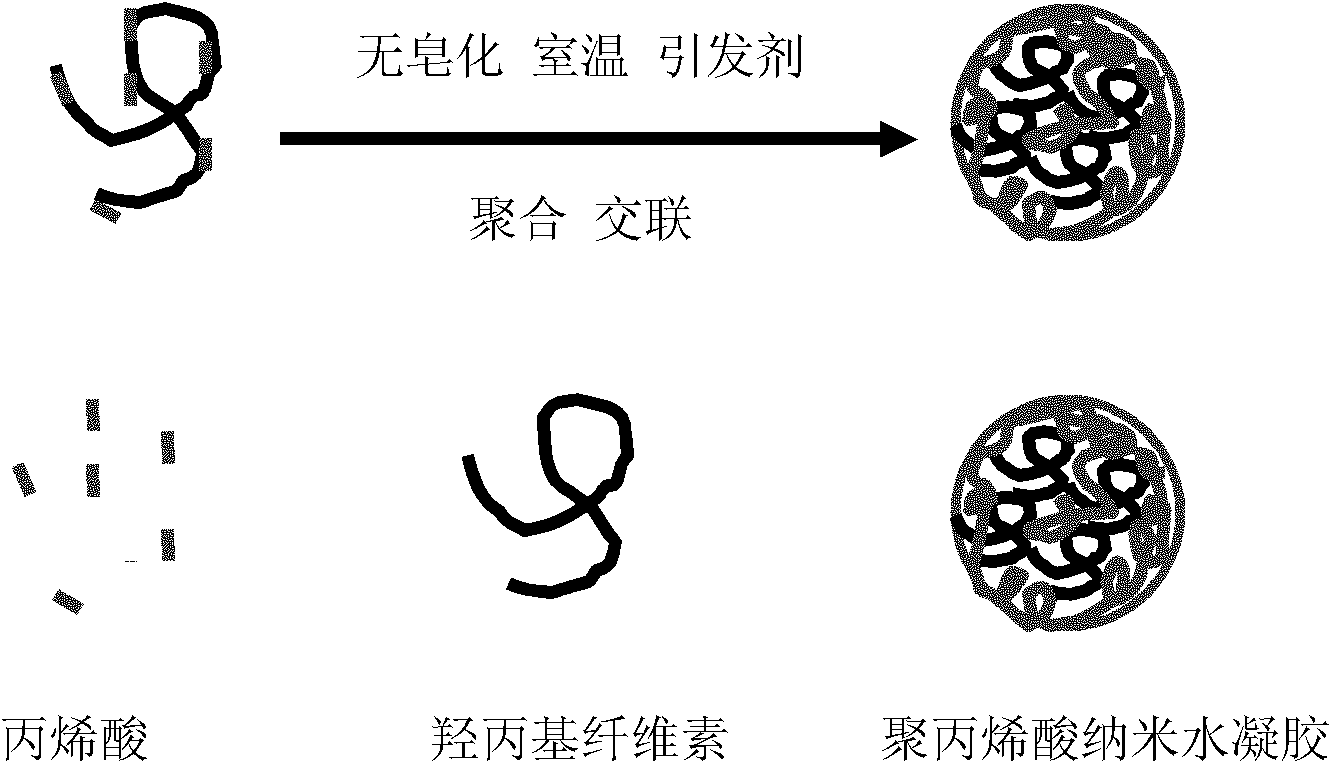

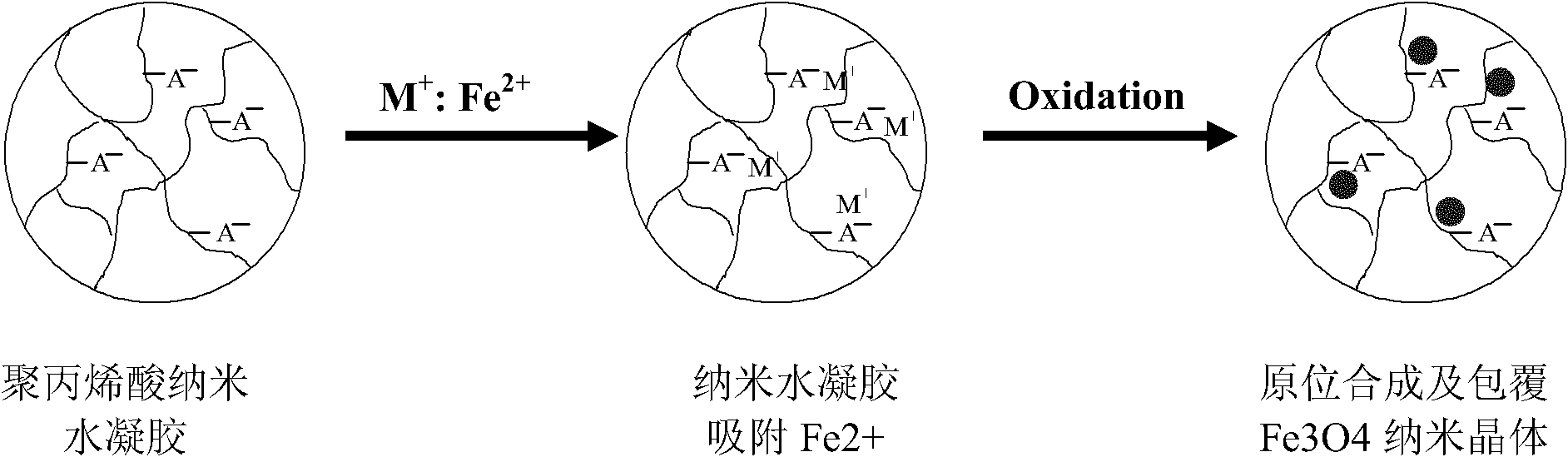

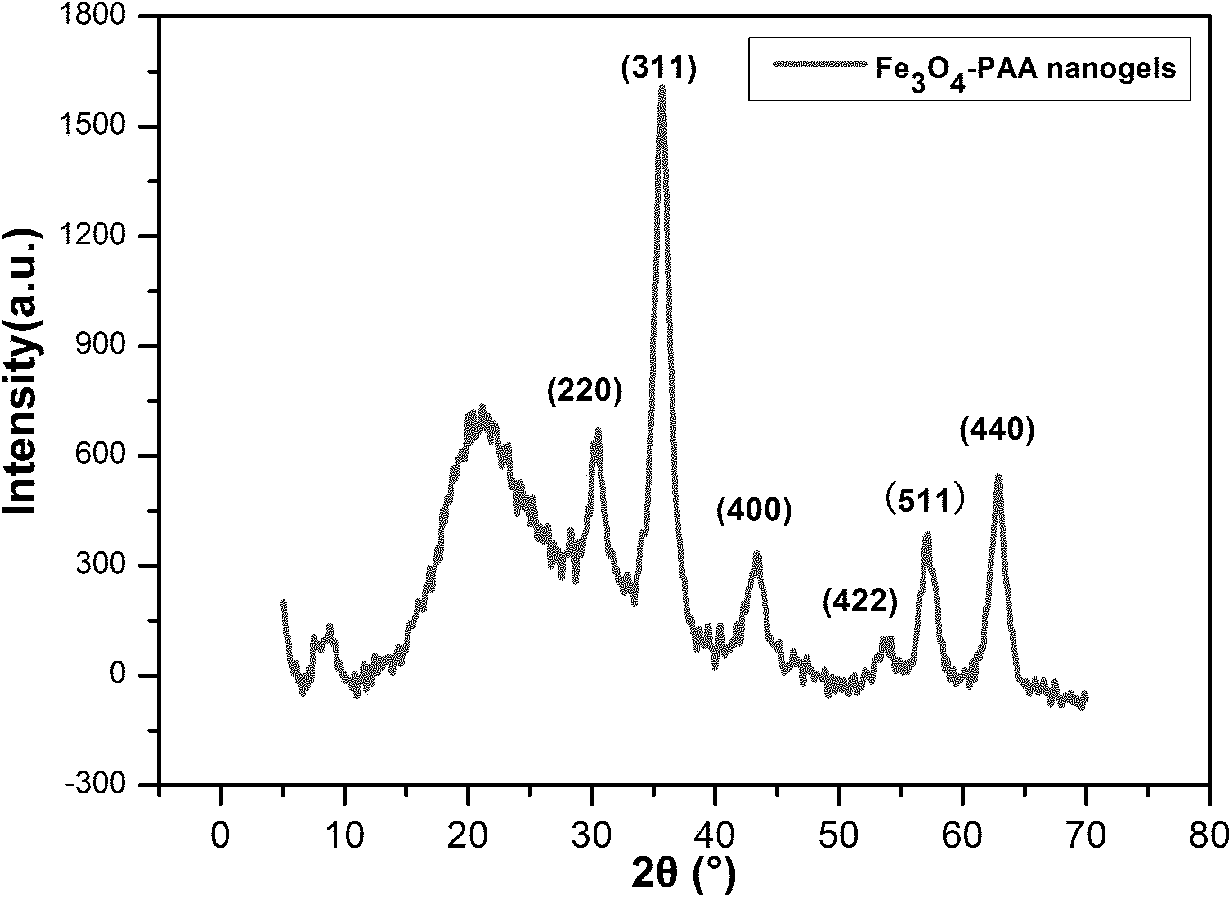

[0039] The steps of this embodiment are as follows: (1) 2g hydroxypropyl cellulose (HPC) powder (average M w =1.0×10 5 ) was dissolved in 98g deionized water, magnetically stirred for 1 day, and prepared into a 2% (wt%) HPC homogeneous solution; (2) at room temperature, 5g2% (wt%) HPC solution and 0.1gBis were dissolved in 93g Deionized water, stirred for 15min; (3) Add 2g of acrylic acid and 0.05g of APS, in N 2 Stirring under protection for 45min; (4) warming up to 28°C, adding 0.05g TEMED to initiate polymerization; (5) neutralizing the prepared polyacrylic acid nanohydrogel with sodium hydroxide to pH=6 and then dialyzing for 2 days; (6 ) take 10ml polyacrylic acid nano hydrogel solution and dilute to 100ml, add 0.6gFeSO 4 ·7H 2 O powder, in N 2 Stir all night under protection and dialyze for 1 day; (7) in N 2 Add 0.03gNaNO under protection 2 powder and stirred for 2 hours, then added 5ml of ammonia water until the solution turned from green to black, took it out and...

Embodiment 2

[0041] The steps of this embodiment are as follows: (1) 2g hydroxypropyl cellulose (HPC) powder (average M w =1.0×10 5 ) was dissolved in 98g deionized water, magnetically stirred for 1 day, and prepared into a 2% (wt%) HPC homogeneous solution; (2) at room temperature, 5g2% (wt%) HPC solution and 0.1gBis were dissolved in 93g Deionized water, stirred for 15min; (3) Add 2g of acrylic acid and 0.05g of APS, in N 2 Stirring under protection for 45min; (4) warming up to 28°C, adding 0.05g TEMED to initiate polymerization; (5) neutralizing the prepared polyacrylic acid nanohydrogel with sodium hydroxide to pH=7 and then dialyzing for 2 days; (6 ) take 10ml polyacrylic acid nano hydrogel solution and dilute to 100ml, add 0.6gFeSO 4 ·7H 2 O powder, in N 2 Stir all night under protection and dialyze for 1 day; (7) in N 2 Add 0.03gNaNO under protection 2 The powder was stirred for 2 hours, then 5ml of ammonia water was added until the solution turned from green to black, and the...

Embodiment 3

[0043] The steps of this embodiment are as follows: (1) 2g hydroxypropyl cellulose (HPC) powder (average M w =1.0×10 5 ) was dissolved in 98g deionized water, magnetically stirred for 1 day, and prepared into a 2% (wt%) HPC homogeneous solution; (2) at room temperature, 5g2% (wt%) HPC solution and 0.1gBis were dissolved in 93g Deionized water, stirred for 15min; (3) Add 2g of acrylic acid and 0.05g of APS, in N 2 Stirring under protection for 45min; (4) warming up to 28°C, adding 0.05g TEMED to initiate polymerization; (5) neutralizing the prepared polyacrylic acid nanohydrogel with sodium hydroxide to pH=6 and then dialyzing for 2 days; (6 ) take 20ml polyacrylic acid nano hydrogel solution and dilute to 100ml, add 1gFeSO 4 ·7H 2 O powder, in N 2 Stir all night under protection and dialyze for 1 day; (7) in N 2 Add 0.03gNaNO under protection 2 The powder was stirred for 2 hours, then 5ml of ammonia water was added until the solution turned from green to black, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com