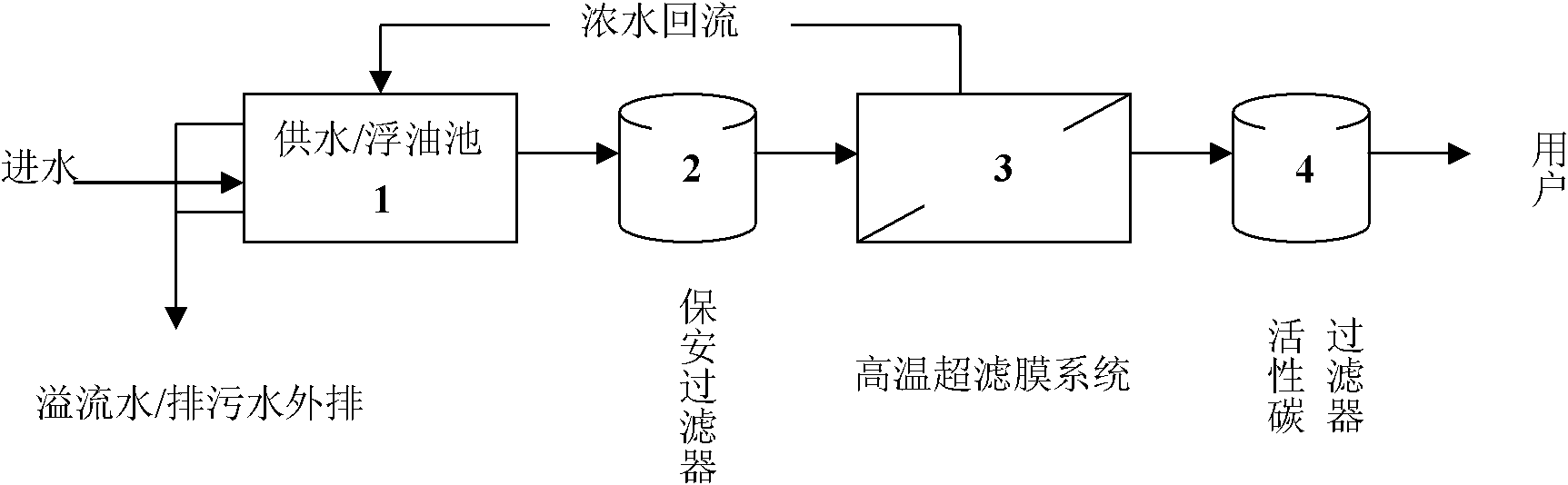

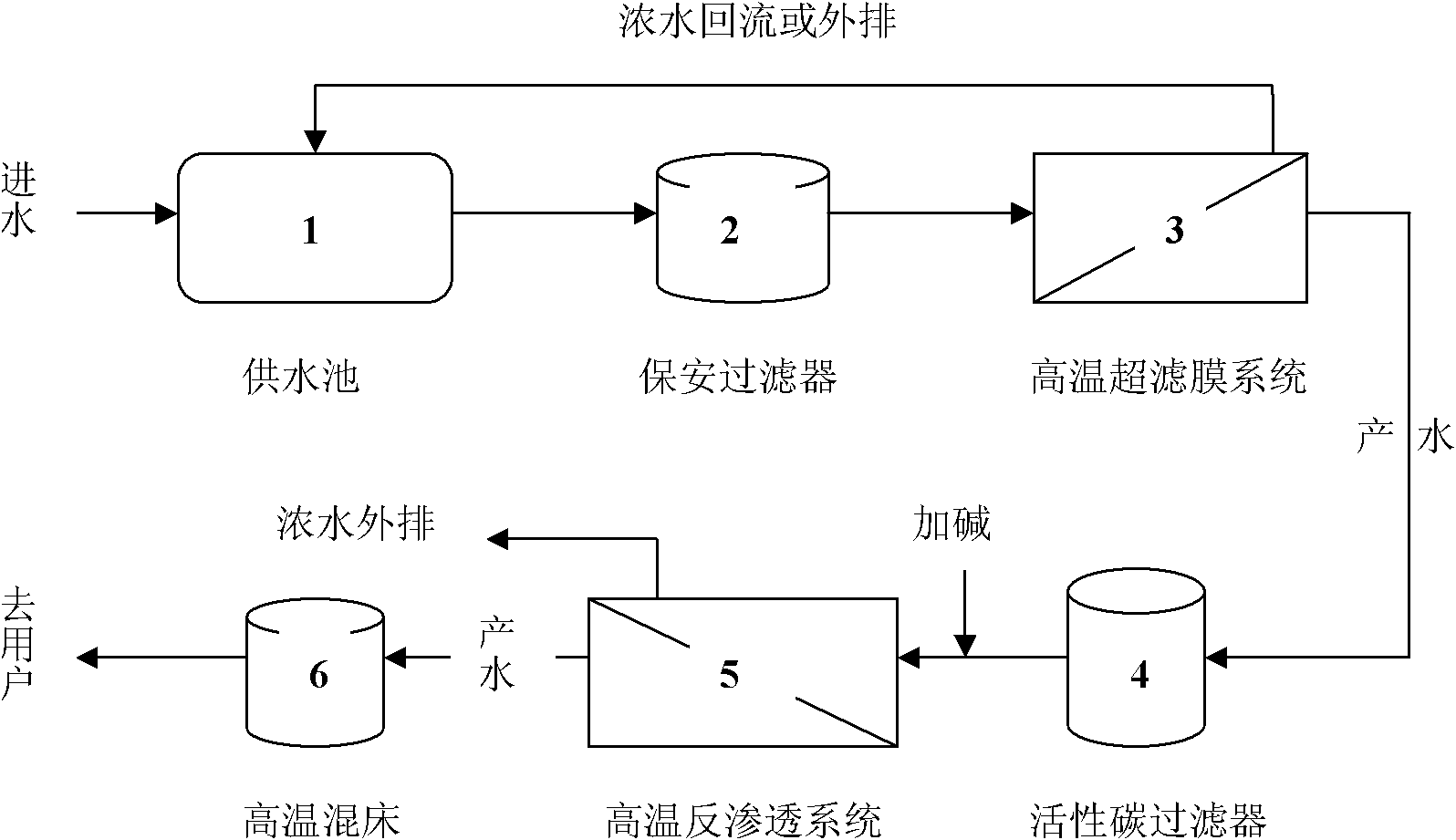

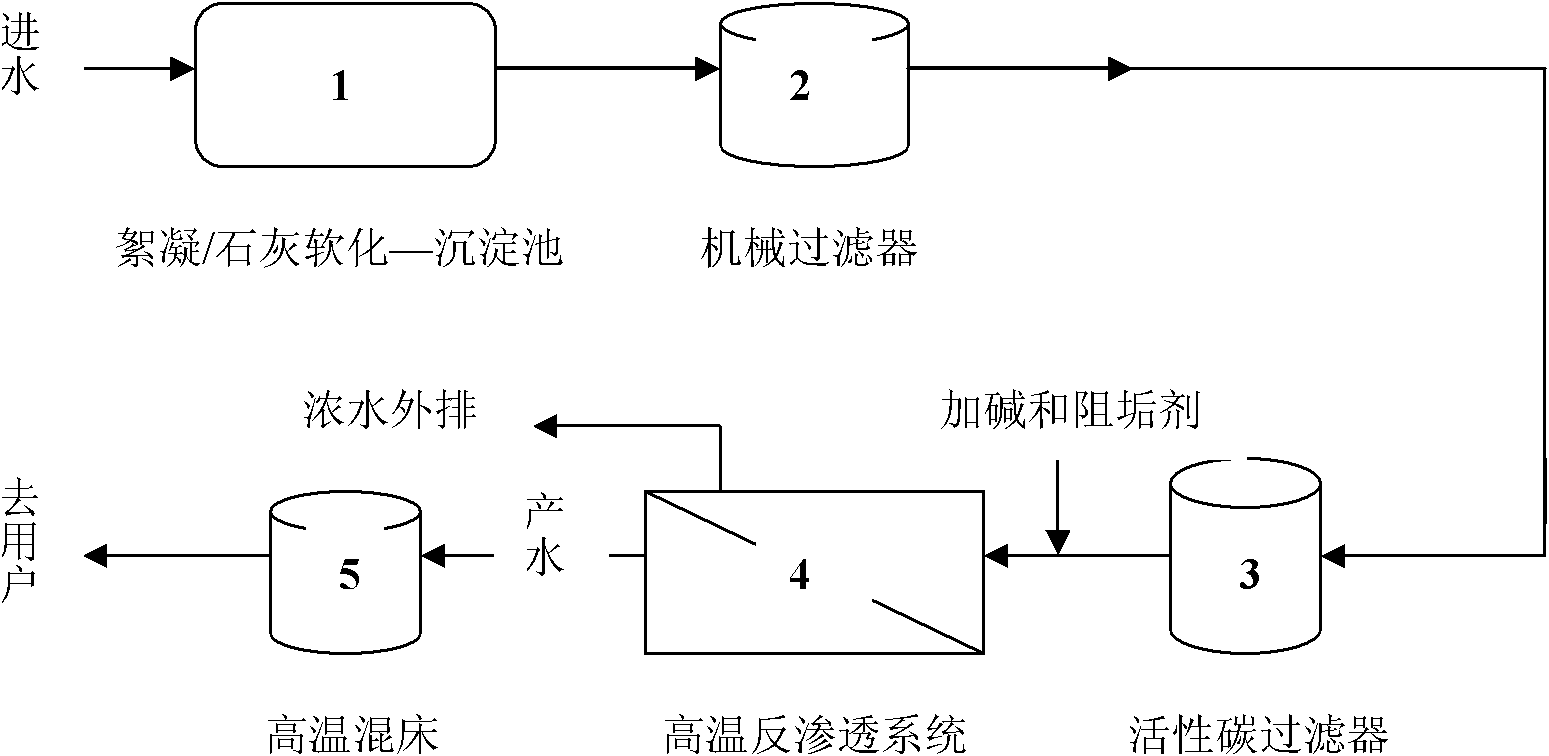

Process for purifying and recycling hot water by membrane method

A hot water and process technology, applied in the fields of water treatment, reclaimed water reuse and energy recovery, can solve the problems of low iron and silicon removal rate, limited application range, easy fouling and blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0050] Implementation case 1: Degreasing test of oily hot water. The raw water is the cooling water of a slightly oily air compressor in an oil refinery (the first-level desalted water is used as the cooling water). The water temperature is 51--55°C. Type ultrafiltration membrane degreasing treatment, the system recovery rate is 90%, the test results are shown in Table 1:

[0051] Table 1 Air compressor cooling water degreasing test data

[0052]

[0053] The raw water used in the test is the air compressor cooling water of an oil refinery of a petrochemical company. Its water quality is similar to that of the steam heating condensed water of an oil refinery. The oil content in the water is low, mainly lubricating oil for the shaft of the air compressor. According to the test results, the ultrafiltration membrane has a very high removal rate of oil in water - greater than 95%, while the ultrafiltration membrane has a low removal rate of silica in water, mainly due to the co...

Embodiment 2

[0054] Example 2: Degreasing test of wet copper raffinate in a gold smelting plant. The test temperature is 36-43°C. The ultrafiltration membrane adopts a 0.01um roll-type high-temperature ultrafiltration degreasing membrane for degreasing treatment test. The raw water is the raffinate of the copper smelter. After the raw water is deoiled, it provides qualified influent water for the reverse osmosis concentration treatment. The test data are shown in Table 2:

[0055] Table 2 Test data of ultrafiltration membrane oil removal effect of copper smelting raffinate

[0056]

[0057] According to the test data analysis, the ultrafiltration membrane has a very good removal effect on the oil in the copper raffinate. Since the removal rate of the ultrafiltration membrane to the floating oil and emulsion in the water is close to 100%, the copper raffinate In the acidic environment, the oil basically exists in the state of slick oil and emulsified oil, and the oil in the water comes f...

Embodiment 3

[0058] Example 3: High temperature reverse osmosis desalination, organic matter test and activated carbon adsorption test. The test raw water is slightly polluted condensate water from the refinery, the test temperature is 45-50°C, and the recovery rate of the membrane system is 90%. The test results are shown in Table 3:

[0059] Table 3 Reverse osmosis desalination, organic matter removal and activated carbon adsorption test data

[0060]

[0061] According to the test results, the high-temperature reverse osmosis membrane is effective in removing salt and organic matter (TOC) in water, but the effect is not ideal. The removal rate of organic matter decreases. On the other hand, the components that constitute TOC and TDS in water may be organic salts. The removal rate of organic matter in water by reverse osmosis membranes will vary with the composition of organic matter. In addition, when the content of salt and organic matter in water is low , the detachment rate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com