Method for recovering base materials in classification by thermally cracking organic polymer mixtures and device thereof

An organic polymer, thermal cracking technology, applied in plastic recycling, recycling technology, educts and other directions, can solve the problems of difficult pressure balance control, affecting operation safety, increasing processing costs, etc., to improve reusability and improve The effect of safe operation and increased utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

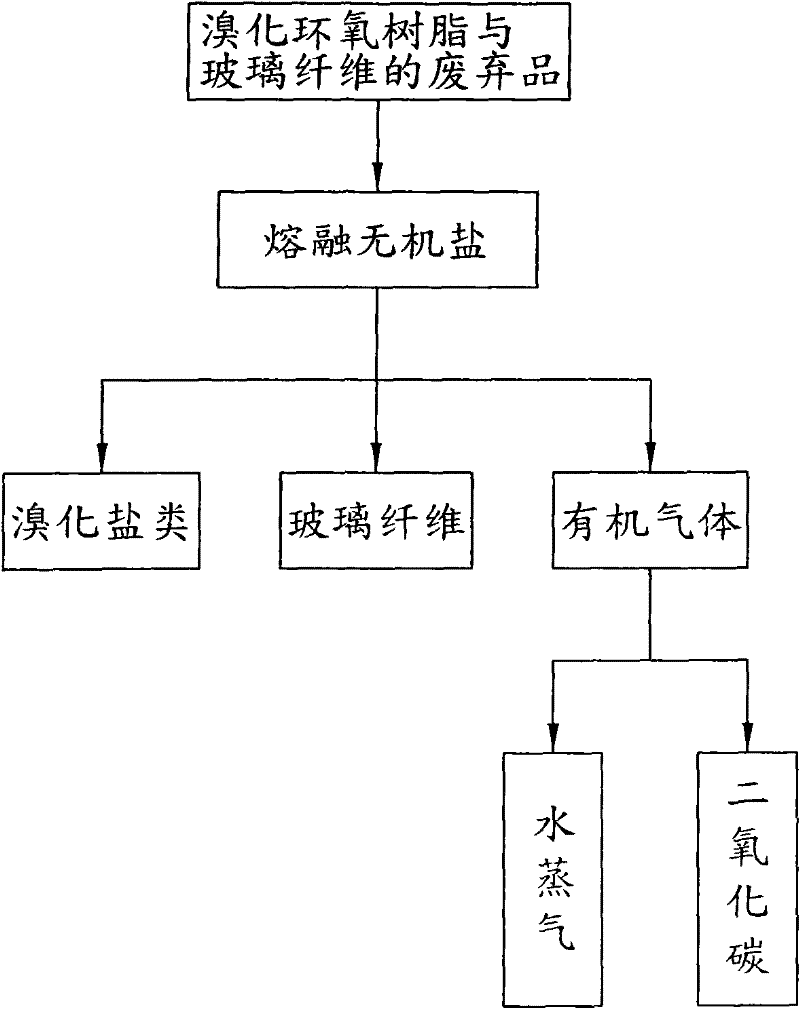

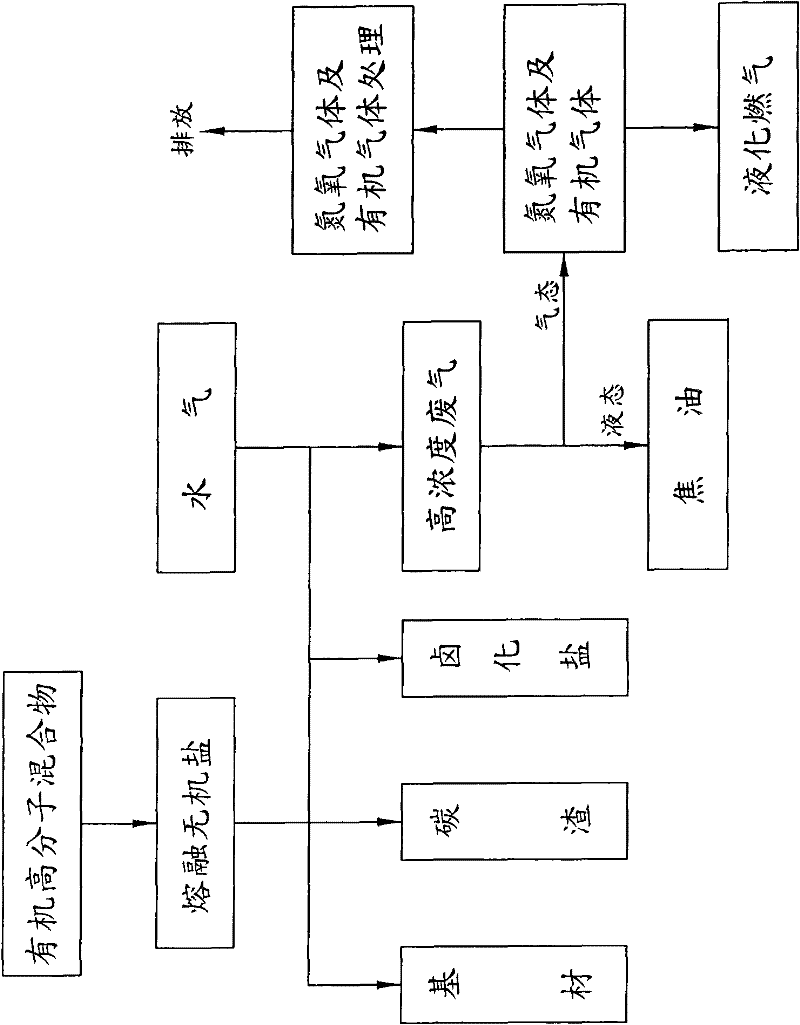

[0056] see figure 2 Shown is the thermal cracking recovery flow chart of the present invention's thermal cracking organic polymer mixture to classify and recover the base material method and its device. The organic polymer mixture is dropped into molten inorganic salt (nitrate or nitrite), and the molten A closed liquid pyrolysis reaction device is formed to heat the polymer, and the pyrolysis of the polymer will form carbon residue, tar, organic gas, etc., and the halogen elements in the polymer will also be released with the thermal cracking, and the highly active metals in the molten salt such as : Lithium, sodium, potassium, rubidium, cesium, and francium will also combine with halogen elements such as fluorine, chlorine, bromine, iodine, and astatine during thermal cracking to form halide salts and nitrogen oxides. During the pyrolysis reaction, not only will the structure of the polymer material be destroyed, but the organic polymer mixture will be decomposed into organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com