Method for preparing microbial oil by fermenting cassava starch and preparing biomouldsel from microbial oil

A microbial oil and cassava starch technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low reducing sugar yield and cumbersome pretreatment steps, and achieve low price, environmental friendliness, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

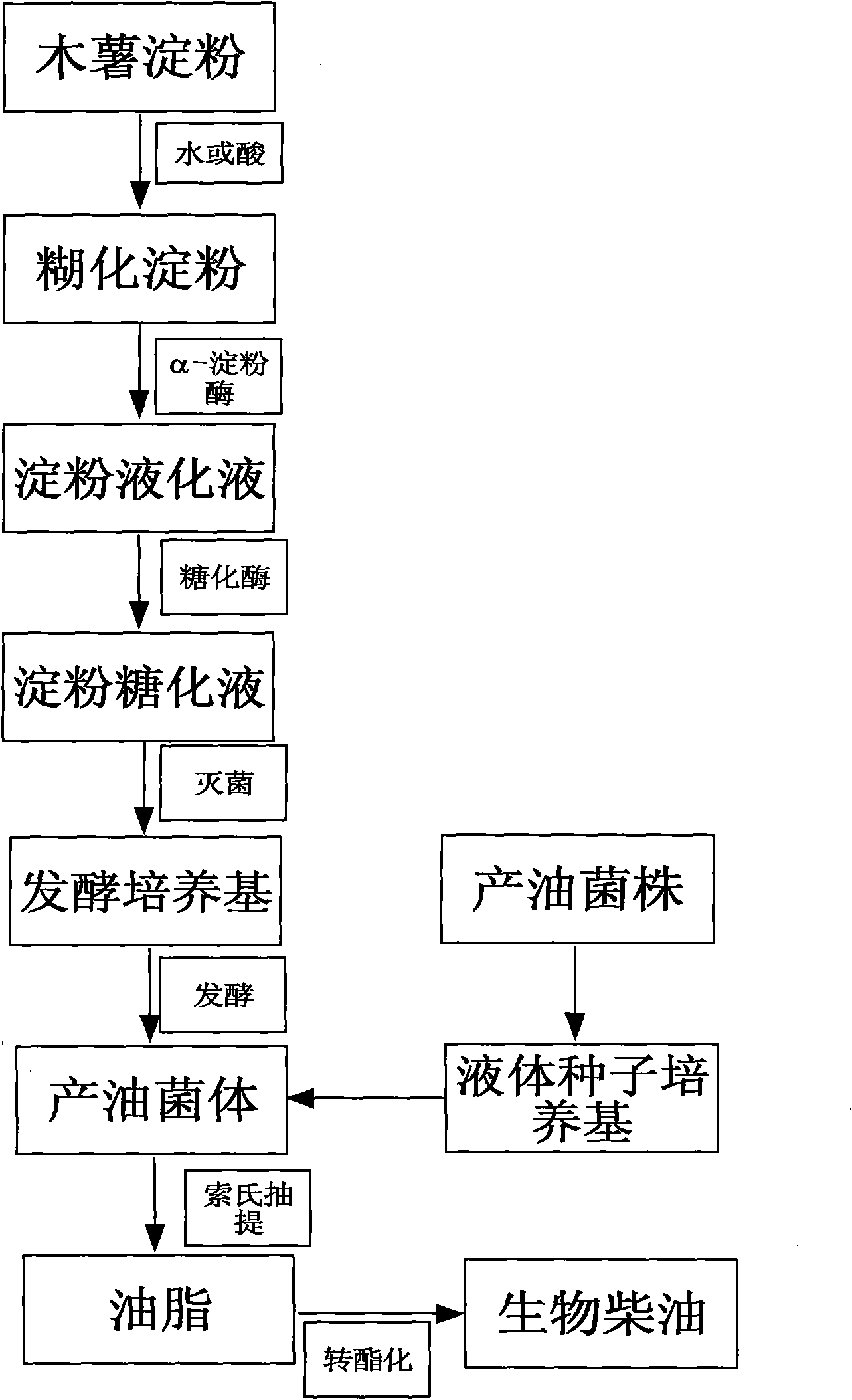

[0032] 1. Tapioca starch pretreatment

[0033] Add the cassava starch raw material into tap water and mix it into a starch slurry with the ratio of water and starch raw material mass ratio of 3:1; adjust the pH value of the starch slurry at 5.5, add α-amylase to the starch slurry, and add α-amylase The amount of enzyme is 2U / g dry weight of starch, liquefied at 90°C for 2 hours to obtain starch liquefaction solution; adjust the pH value of starch liquefaction solution to 4.0 and then add glucoamylase, the amount of glucoamylase added is 400U / g dry starch Heavy, saccharified at 60°C for 2 hours to obtain a starch saccharification solution, the concentration of reducing sugar was determined to be 215g / L, and it was used as a carbon source for the fermentation medium for subsequent use;

[0034] 2. Fermentation

[0035] (1) Strain: Trichosporium dermatosa B3

[0036] (2) Culture medium: seed medium: glucose 70g / L, NH 4 NO 3 0.5g / L, yeast extract powder 1g / L, MgSO 4 ·7H 2 O...

Embodiment 2

[0042] 1. cassava starch pretreatment is the same as embodiment 1

[0043] 2. Fermentation

[0044] (1) Strain: Trichosporium dermatosa B3

[0045] (2) culture medium: seed culture medium is the same as embodiment 1

[0046] Fermentation medium: the carbon source is cassava starch saccharification solution, and its dosage is 80g / L based on its reducing sugar content, NH 4 NO 3 0.5g / L, yeast extract powder 3g / L, MgSO 4 ·7H 2 O 0.4g / L, KH 2 PO 4 0.75g / L, CaCl 2 2H 2 O 0.4g / L, pH is 6.0;

[0047] (3) fermentation mode is the same as embodiment 1, and the fermentation culture time is 60h;

[0048] (4) Fermentation result

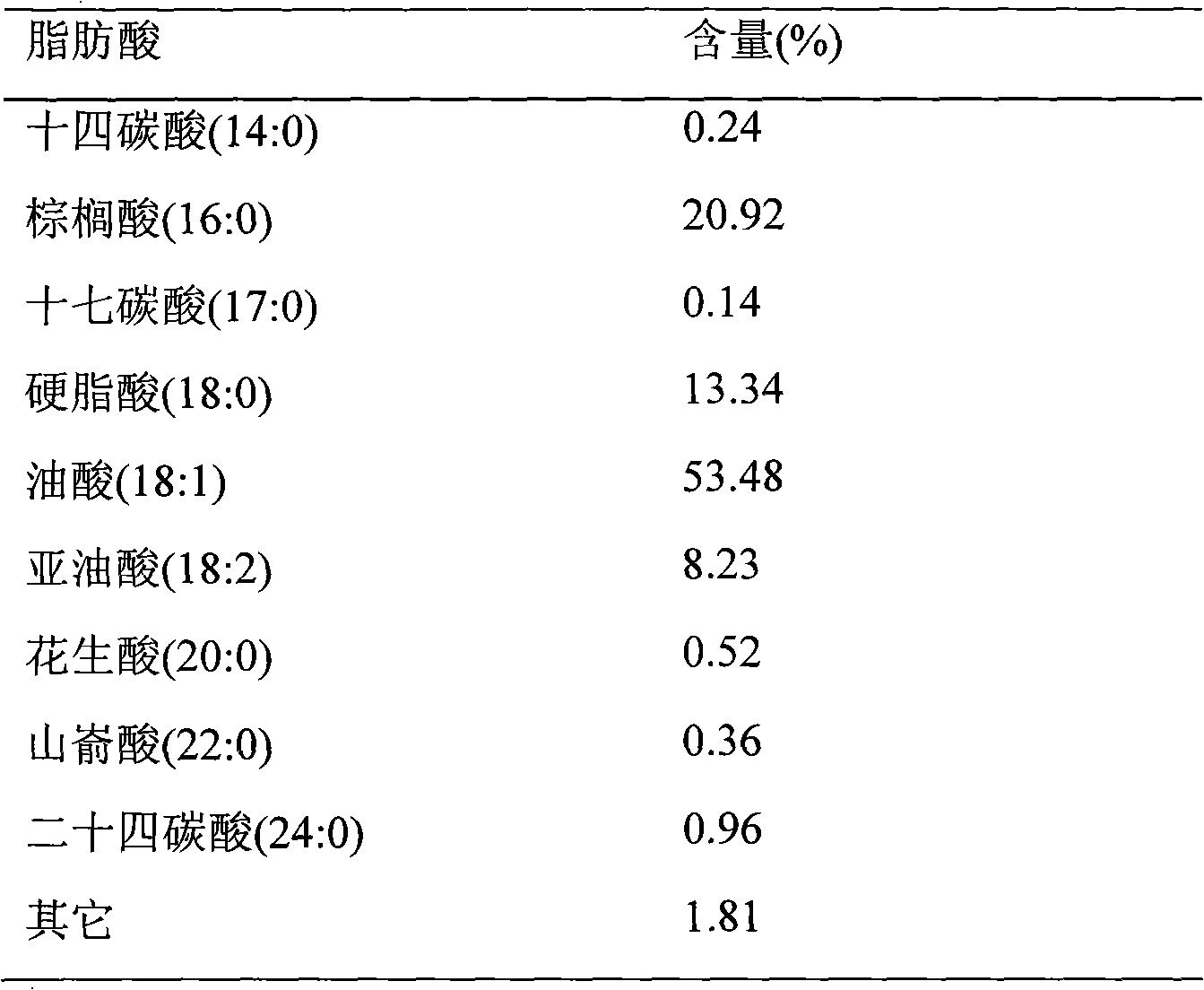

[0049] After 60 hours of fermentation, its biomass reached 28.2g / L. Petroleum ether was used as an organic solvent combined with a Soxhlet extractor to heat and reflux in a water bath at 80° C. for 6 hours to extract oil from the bacteria, and the oil content reached 36.5%.

Embodiment 3

[0051] 1. Tapioca starch pretreatment

[0052] Add tapioca starch raw material into tap water and mix into starch slurry with the ratio of water and starch raw material mass ratio of 4:1; adjust the pH value of starch slurry at 5.5, add α-amylase to starch slurry, α-amylase adds The amount of enzyme is 6U / g starch dry weight, liquefied at 90°C for 2 hours to obtain starch liquefaction solution; adjust the pH value of starch liquefaction solution to 4.0 and then add glucoamylase, the amount of glucoamylase added is 300U / g starch dry Heavy, saccharified at 60°C for 2 hours to obtain a starch saccharification liquid, the concentration of reducing sugar was determined to be 240g / L, which was used as a carbon source for the fermentation medium for later use;

[0053] 2. Fermentation

[0054] (1) Strain: Trichosporium dermatosa B3

[0055] (2) Culture medium: seed medium: glucose 70g / L, NH 4 NO 3 0.5g / L, yeast extract powder 1g / L, MgSO 4 ·7H 2 O0.4g / L, KH 2 PO 4 0.75g / L, C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com