Method for preparing corrosion-resistant super-hydrophobic coating and product thereof

A super-hydrophobic coating and corrosion-resistant technology, which can be used in coatings, metal material coating processes, devices for coating liquids on surfaces, etc., and can solve problems such as high cost and poor mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

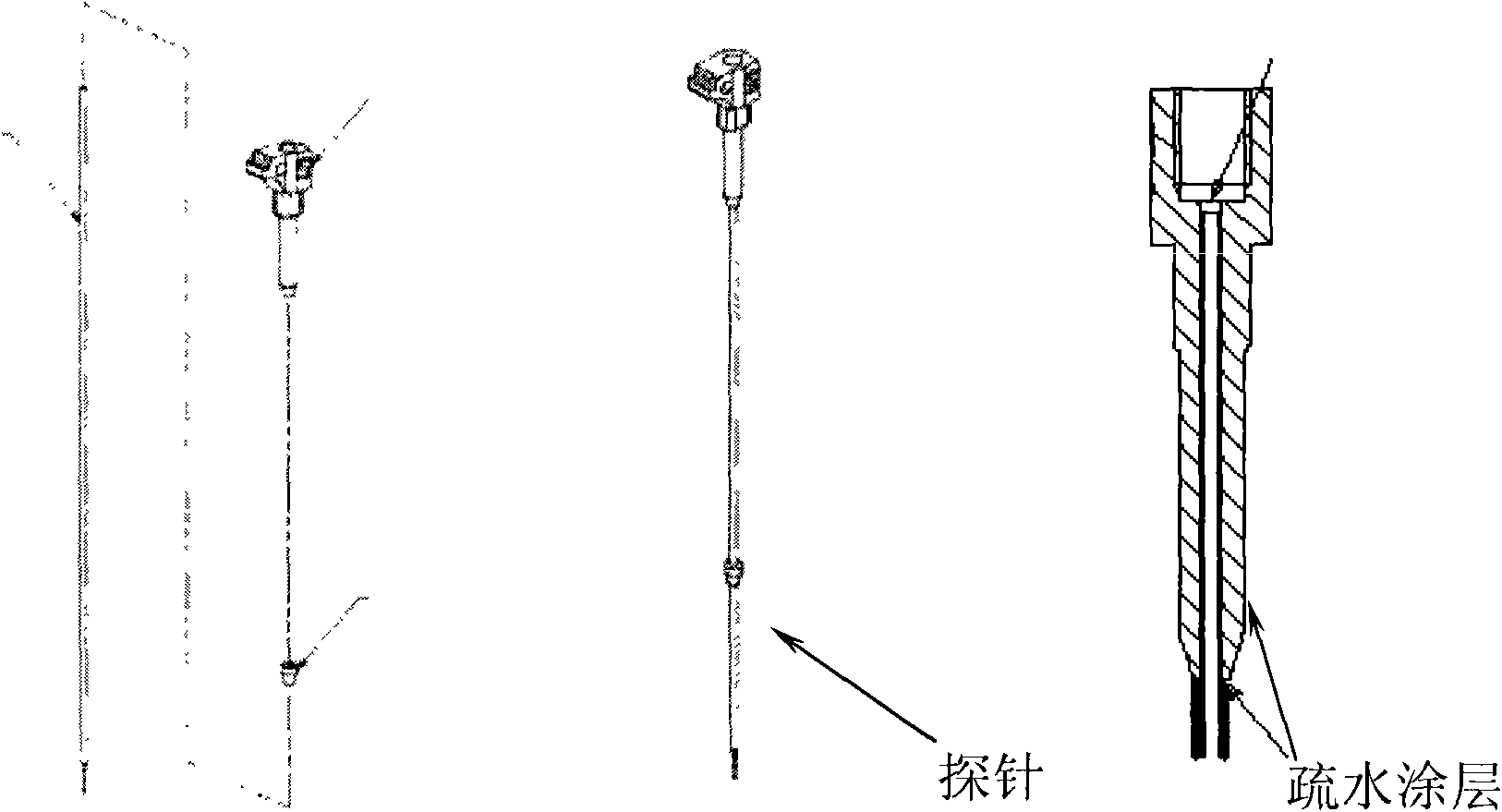

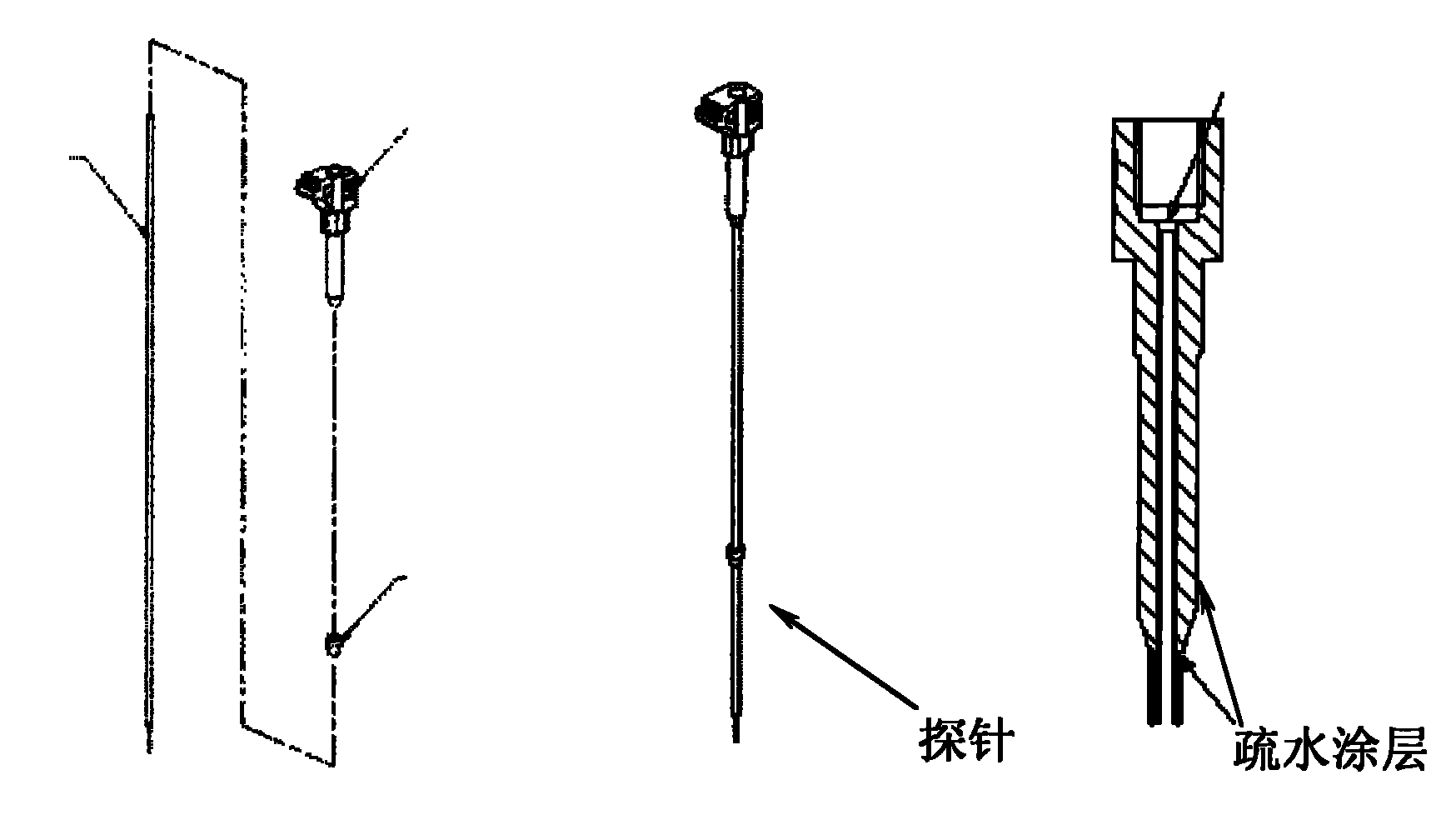

[0032] From the perspective of the entire coating preparation method, the processing temperature of the system is safe, below any important melting point of iron metal. The coating is an inert coating, which is not only corrosion-resistant, but also does not react with protein or hemoglobin, and can be widely used in various biochemical detections. The coated probe prepared by the method of the invention can be sterilized by high pressure and chemically, and is also suitable for microwave or gamma ray sterilization. In conclusion, the ceramic, silicon compound, metal oxide or metal nitride coating is a very durable protective coating for a variety of biochemical detection probe materials such as polished stainless steel. Also routinely used in deep small hole IDs and guaranteed to have a uniform conformal surface.

[0033] In the most preferred embodiment, the formed ceramic, silicon compound, metal oxide or metal nitride coating is further modified with a fluoroalkyltrimetho...

Embodiment 1

[0038] Preparation and Characterization of Aluminum Oxide Coating

[0039] The aluminum oxide coating is formed on the surface of the probe with a length of 30 cm and an inner diameter of 0.2 cm by the sol-gel method, and the coating after drying at room temperature is heat-treated at 100-800 ° C for 1-8 hours to form a microscopic particle size of 10 nanometers to 2 microns. structure to increase its surface roughness.

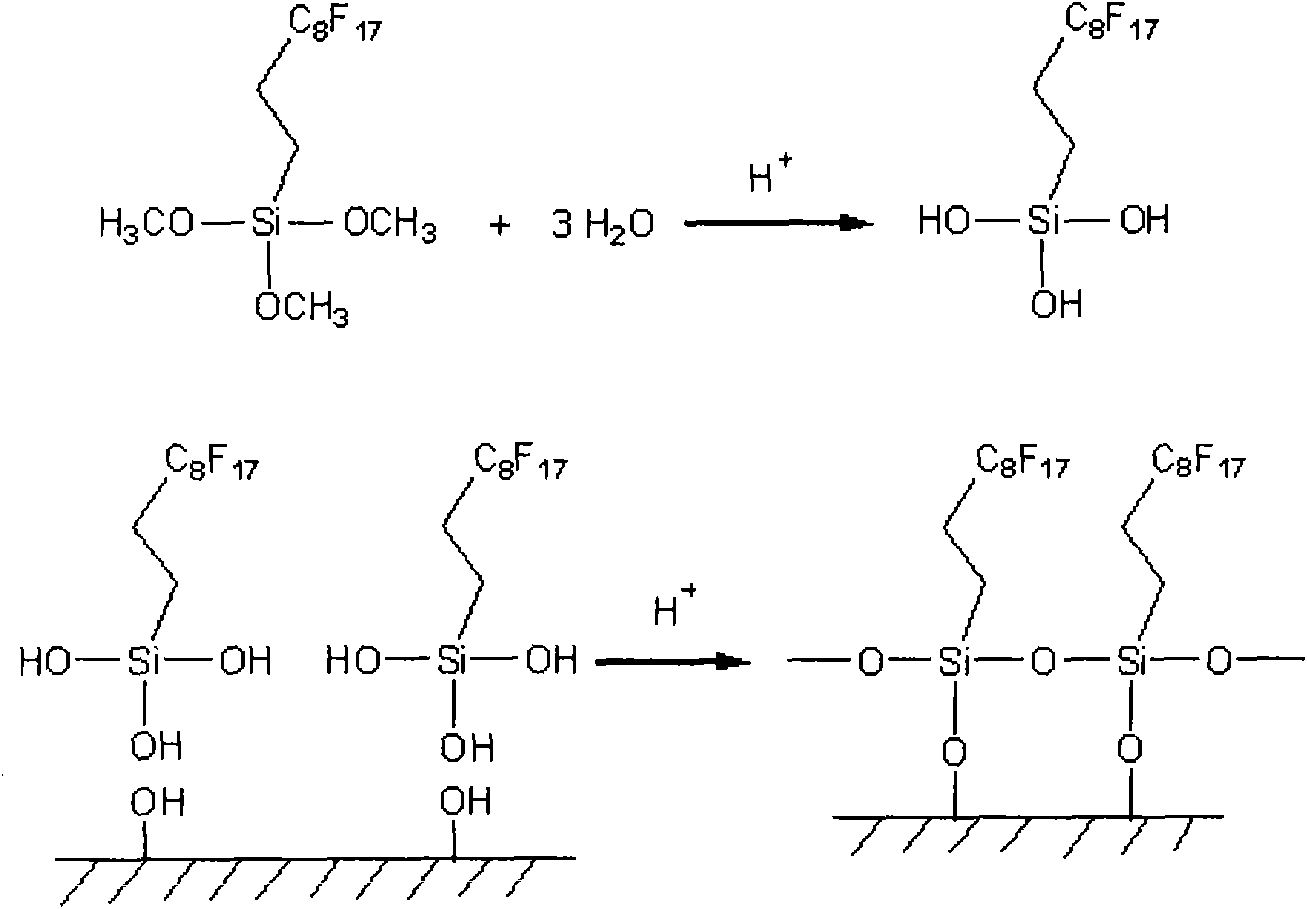

[0040] The fluoroalkyltrimethoxysilane is grafted on the prepared alumina coating to cause a condensation reaction to remove water. The reaction process is as follows: figure 2 As shown, silane was chemically grafted on the surface of the coating to obtain a silane-modified coating.

[0041] The contact angle of the coating to water was measured to be 150°.

Embodiment 2

[0043] Preparation and Characterization of Titanium Dioxide Coating

[0044] A titanium dioxide coating is formed on the surface of the probe with a length of 20 cm and an inner diameter of 0.17 cm by the sol-gel method, and the coating after drying at room temperature is heat-treated at 600 ° C for 8 hours to form a microstructure of 100 nanometers to 2 microns to improve its Surface roughness.

[0045] The fluoroalkyltriethoxysilane is grafted on the prepared titanium dioxide coating, so that condensation reaction occurs, water is removed, and the silane forms a chemical bond to connect on the coating surface to obtain a silane-modified coating.

[0046] The contact angle of the coating to water was measured to be 150°.

[0047] It can be seen that the coatings of ceramics, silicon compounds, metal oxides or metal nitrides prepared in the above examples have super-hydrophobic properties, and their hydrophobicity and inertness greatly reduce the adsorption of samples and red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com