Method for preparing graphene through chemical vapor deposition under cold cavity wall condition

A chemical vapor deposition and graphene technology, which is applied in the field of graphene preparation, can solve the problems of unfavorable high-quality graphene, the influence of graphene growth quality, and the increase of heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

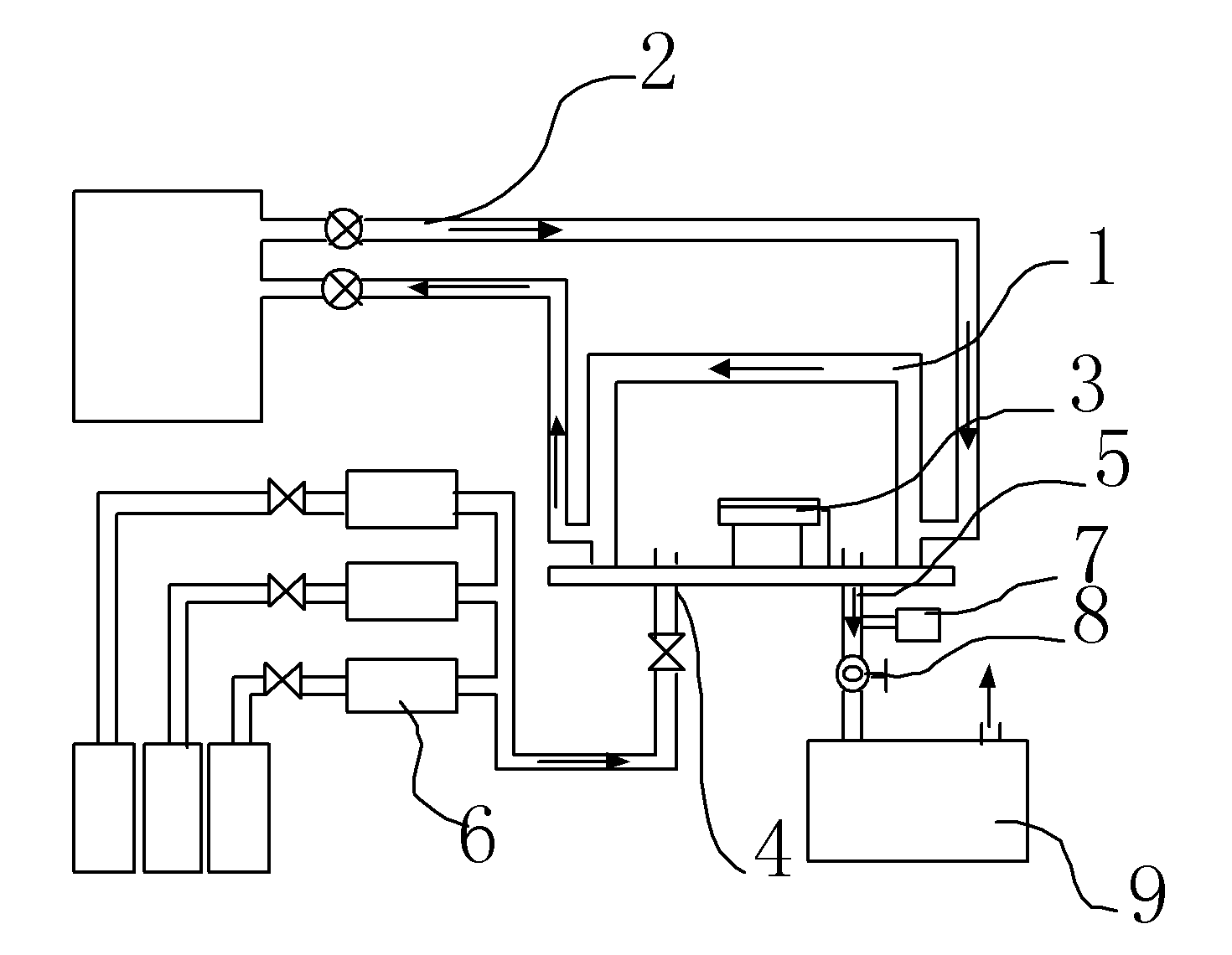

Method used

Image

Examples

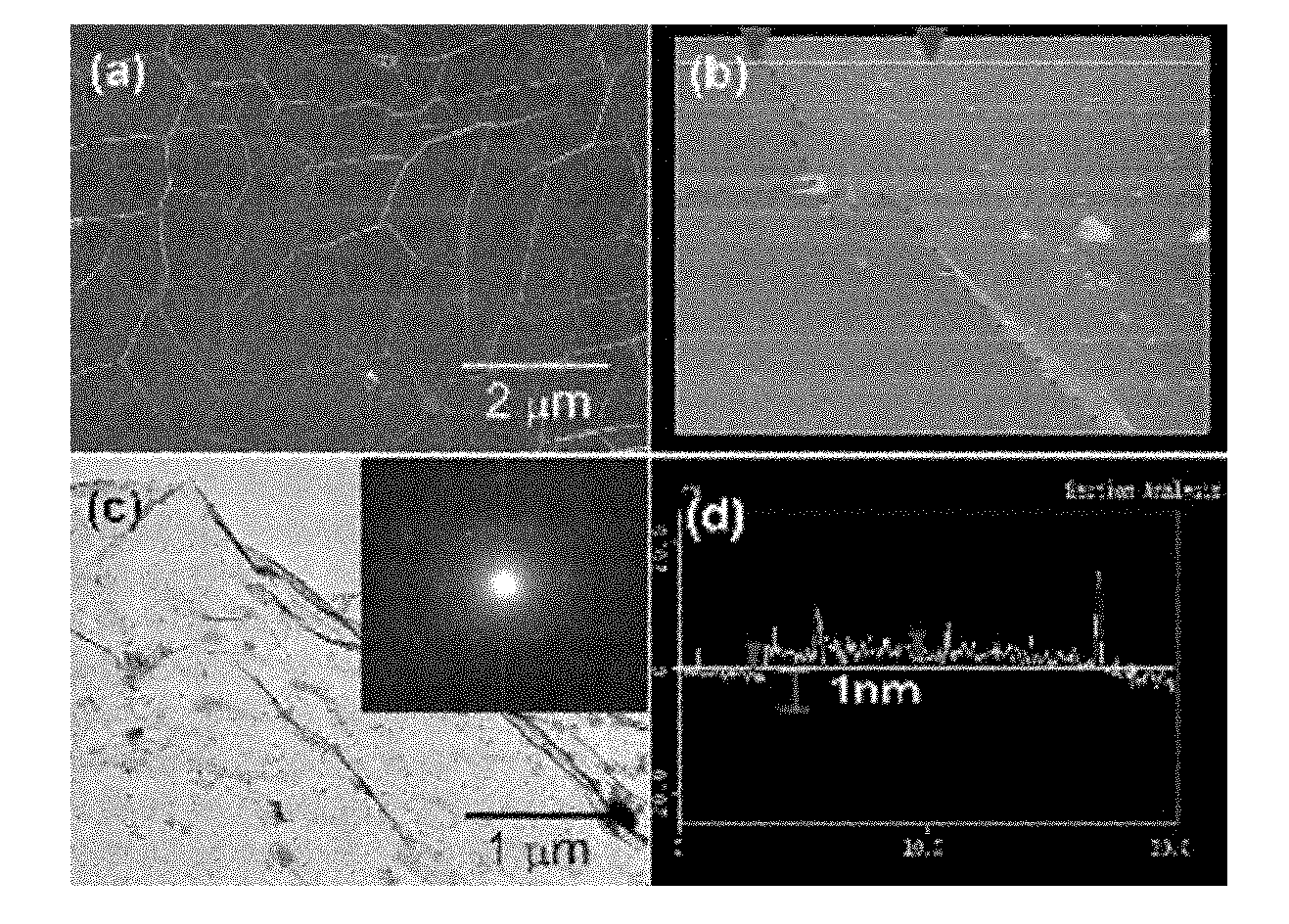

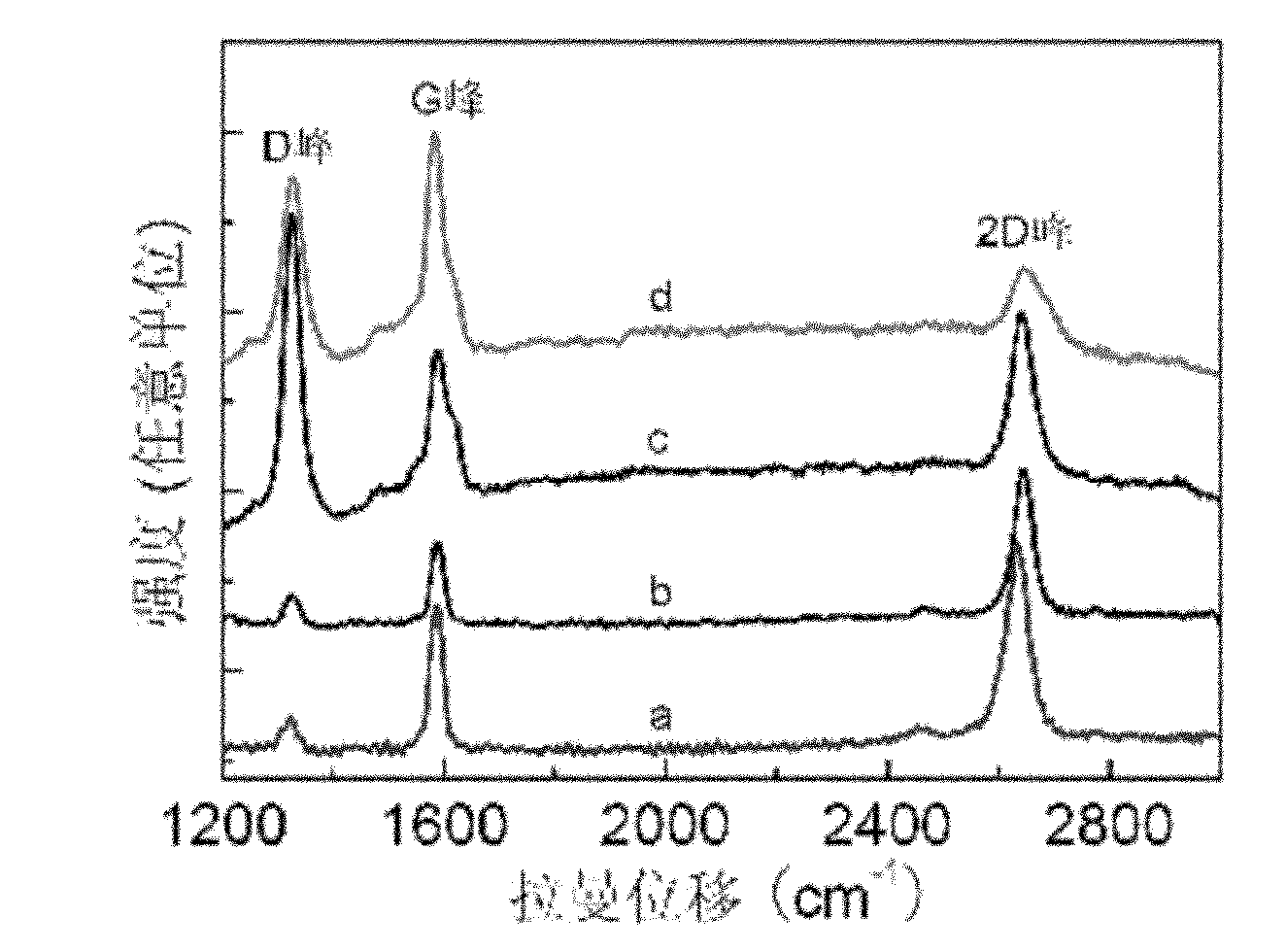

Embodiment 1

[0035] The method of this embodiment 1 is to place the copper foil substrate with an area of 10 mm × 10 mm, a thickness of 25 μm, and argon plasma treatment on the surface on the heating table of the chemical vapor deposition equipment; open the circulating water to cool the cavity wall to 25 ℃; vacuumize, so that the background vacuum of the cavity reaches below 3mTorr; feed the mixed gas of nitrogen (purity 99.999%) and hydrogen (purity 99.999%), nitrogen flow is 700sccm, hydrogen flow is 100sccm, and starts to heat up at a rate of 100°C / min, the chamber pressure is 3Torr; after the substrate temperature reaches 1000°C and is kept warm for 30 minutes, methane gas (purity 99.99%) is introduced, the flow rate is 30sccm, and the duration is 30 minutes; set the substrate cooling rate to 200°C / min, cool down the substrate and stop feeding methane gas; wait for the substrate to cool down to room temperature, stop feeding hydrogen and nitrogen. Graphene can be obtained after the ...

Embodiment 2

[0037] The method of this embodiment 2 is to place the substrate of nickel / silicon dioxide / silicon structure with an area of 10mm×10mm on the heating table of the chemical vapor deposition equipment, wherein the thicknesses of nickel, silicon dioxide and silicon are respectively 300nm and 300nm and 0.5mm; open the circulating water to cool the cavity wall to 25°C; vacuumize the cavity to make the background pressure of the cavity reach 150Torr; only feed nitrogen (purity 99.999%), the nitrogen flow rate is 500sccm, and start to heat up at a rate of 100°C / min, the cavity pressure is 15Torr; after the substrate temperature reaches 1000°C and is kept for 30 minutes, methane gas (purity 99.99%) is introduced, the flow rate is 8sccm, and the duration is 10 seconds; the substrate cooling rate is set to 200°C / min, cool down the substrate and stop feeding methane gas; wait for the substrate to cool down to room temperature, stop feeding hydrogen and nitrogen. Graphene can be obtaine...

Embodiment 3

[0039] The method of this embodiment 3 is to place the substrate of the iron-platinum alloy film / silicon structure with an area of 20mm×20mm on the heating table of the chemical vapor deposition equipment, wherein the thicknesses of the iron-platinum alloy film and the silicon wafer are respectively 200nm and 0.5mm ; Turn on the circulating water to cool the chamber wall to 25°C; vacuumize the chamber so that the background pressure of the chamber reaches 3Torr; feed the mixed gas of helium (purity 99.999%) and hydrogen (purity 99.999%), and the helium flow rate is 600sccm, the flow rate of hydrogen gas is 50sccm, and the temperature starts to rise at a rate of 100°C / min, and the pressure of the chamber is 750Torr; after the substrate temperature reaches 750°C and is kept for 20 minutes, acetylene (purity 99.8%) is started, and the flow rate is 50sccm, which lasts The time is 10 minutes; set the cooling rate of the substrate to 200°C / min, cool down the substrate and stop feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com