Iron group metal material after black surface treatment and manufacturing method thereof

A metal material and surface treatment technology, applied in the direction of metal material coating process, etc., can solve the problems of chrome-free, high cost and economical, and the corrosion resistance of the product cannot be said to have sufficient performance, so as to achieve excellent sliding performance and corrosion resistance The effect of excellent and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

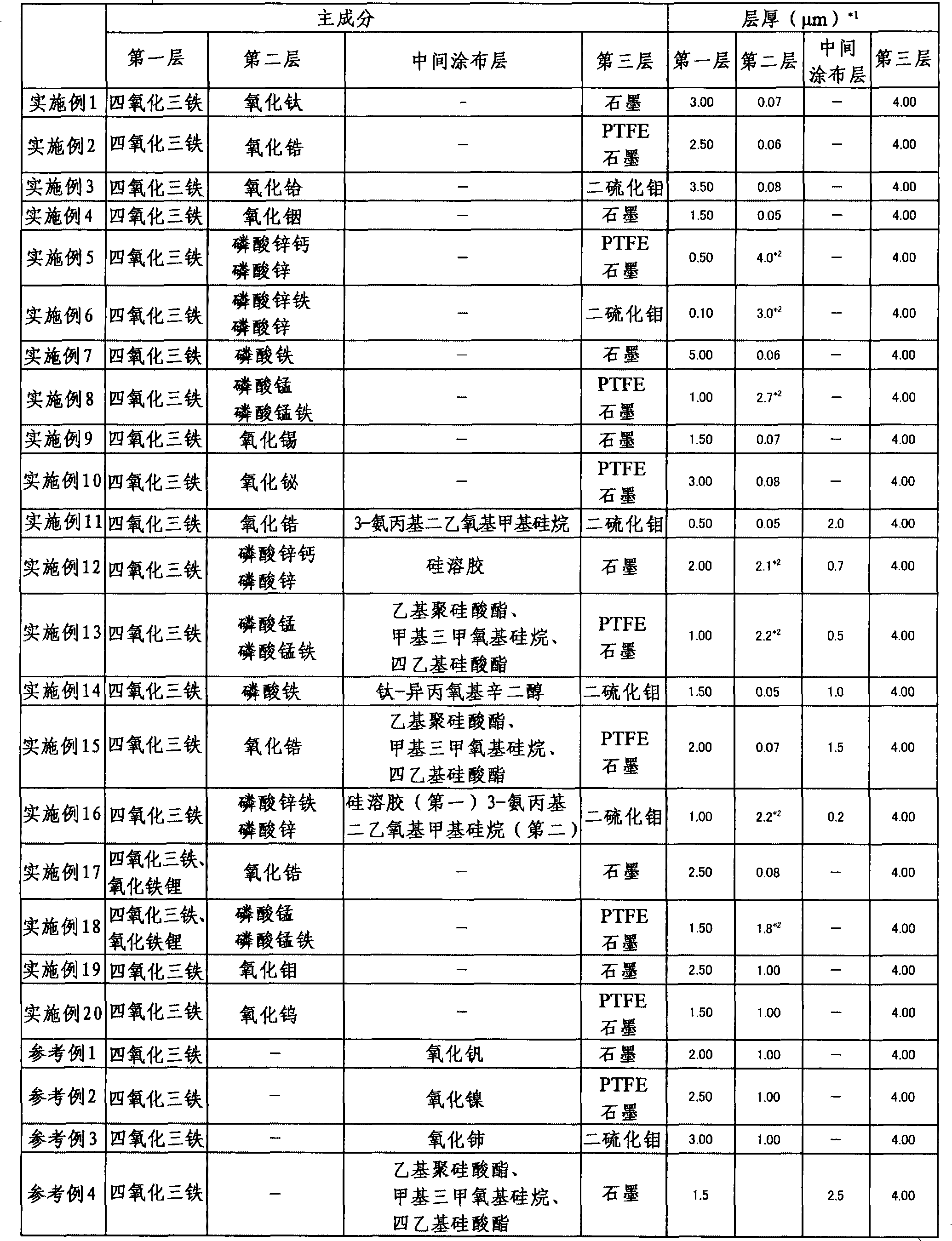

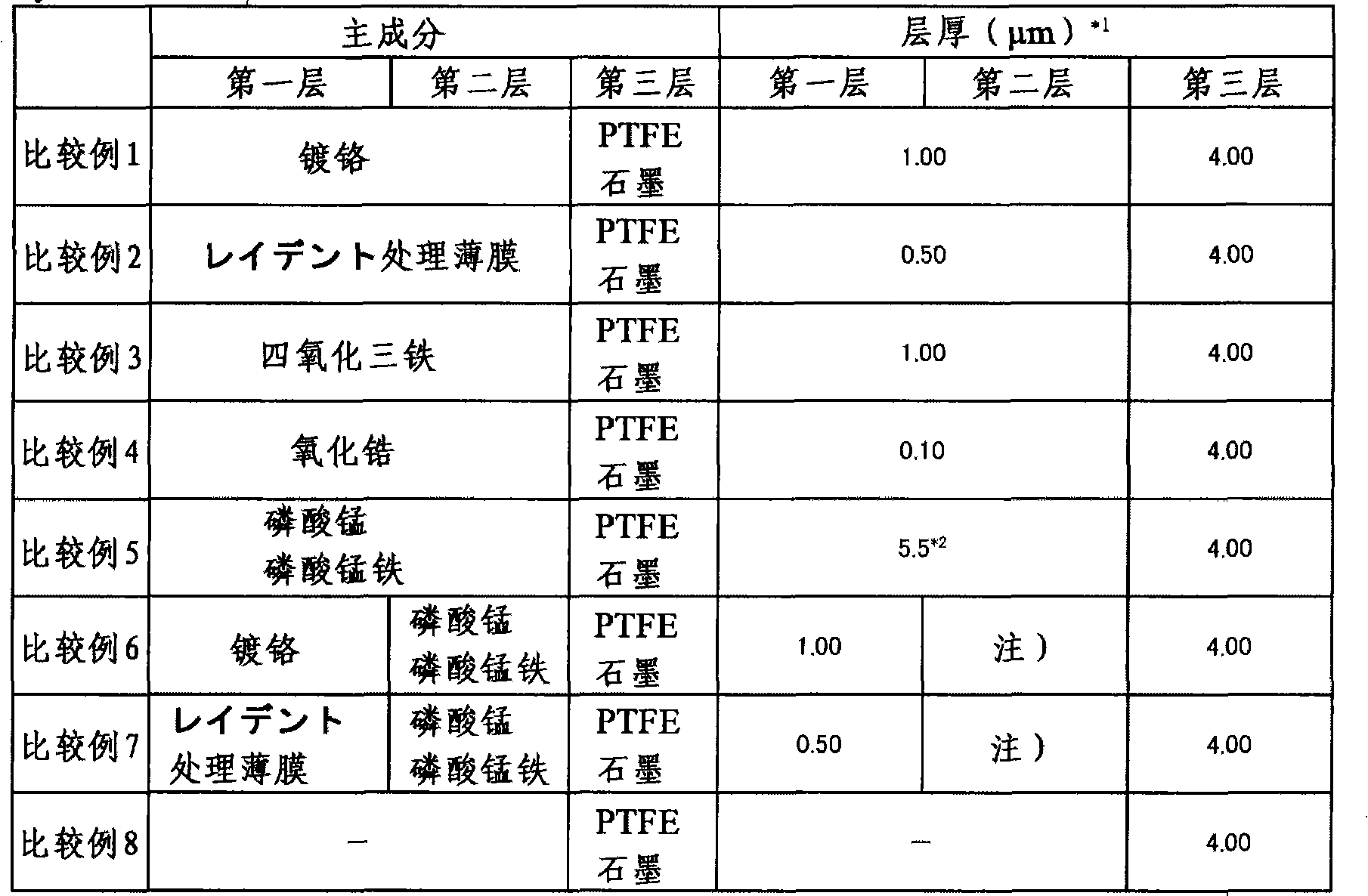

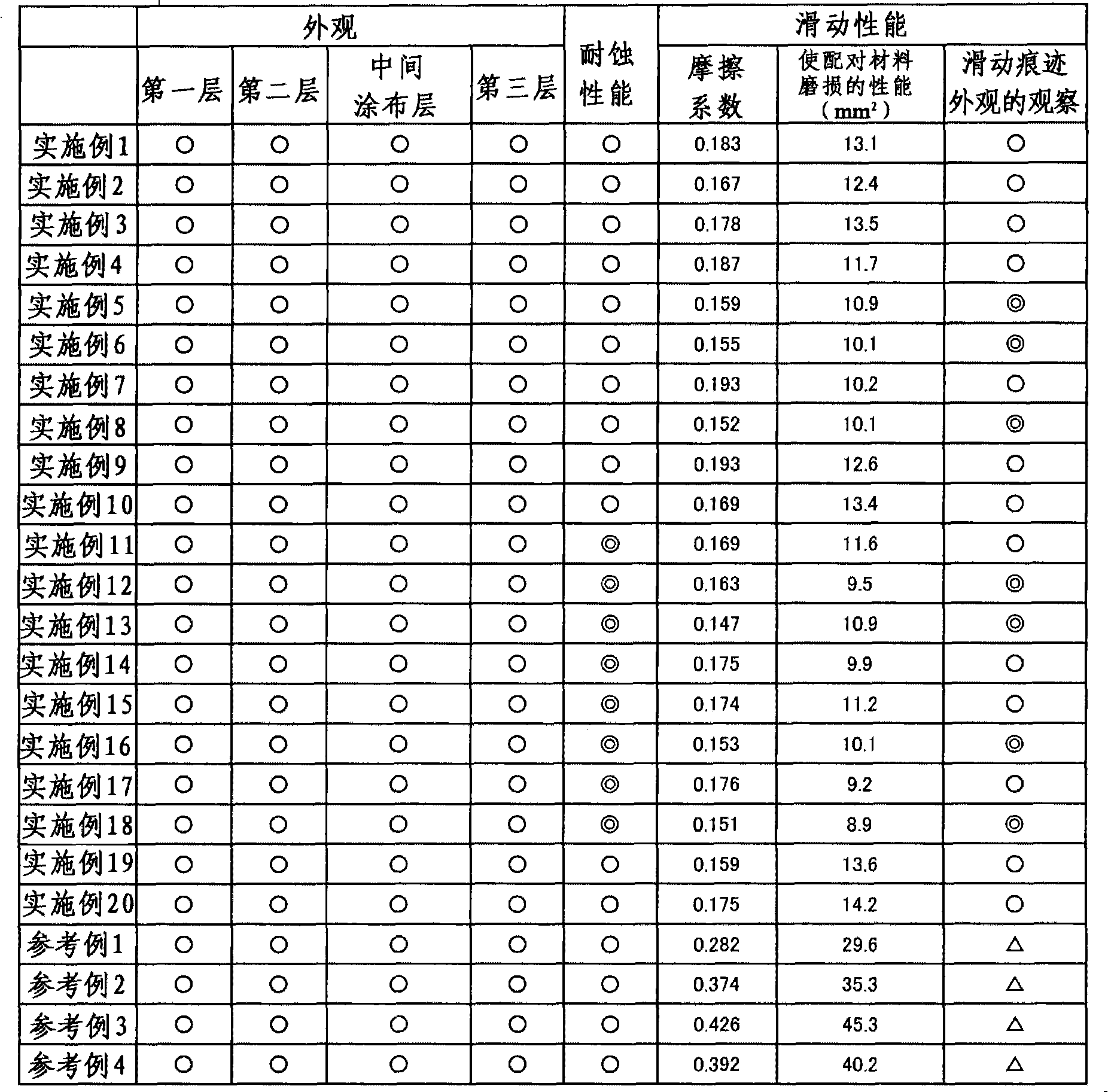

Examples

Embodiment 1~10 and 17~20

[0093] Embodiments 1-10 and 17-20, comparative examples 6-7 are implemented according to the following procedures.

[0094] Alkaline degreasing → washing with water → forming the first layer → washing with water → forming the second layer → washing with water → drying → forming the third layer → baking

Embodiment 11~16

[0095] Embodiments 11-16 are implemented according to the following procedures.

[0096] Alkaline degreasing→Washing→Forming the first layer→Washing→Forming the second layer→Washing→Drying→Forming the middle coating layer→Drying, baking→Forming the third layer→Baking

[0097] Reference examples 1-4 are implemented according to the following procedures.

[0098] Alkaline degreasing→Water washing→Forming the first layer→Washing→Drying→Forming the middle coating layer→Drying, baking→Forming the third layer→Baking

Embodiment 1

[0136] Dilute "Palbratsu A" manufactured by Nippon Parker Seisei Co., Ltd. with tap water to a concentration of 80.5% by mass, use the diluted solution as a blackening agent, heat to 148°C, and degrease the iron-based metal with alkali The material is immersed for 60 minutes, and the first layer mainly composed of ferric iron tetroxide is formed on the surface of the iron-based metal material after the alkali degreasing treatment.

[0137] Use titanium hydrofluoride reagent, nitric acid reagent and hydrofluoric acid reagent to prepare an acidic chemical conversion treatment solution with a titanium concentration of 2000 mg / L, a nitric acid concentration of 10000 mg / L, and a fluorine concentration of 7 mg / L as free fluorine. Then, the chemical conversion treatment liquid is heated to 50° C., and the pH is adjusted to 3.0 with an ammonia water reagent. In the adjusted chemical conversion treatment liquid, the iron-based metal material formed on the first layer is immersed for 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com