Preparation method for carbon nanofiber containing transition metal and nitrogen element and application of carbon nanofiber in fuel-cell catalysts

A technology of carbon nanofibers and transition metals, applied in the direction of fiber chemical characteristics, nanotechnology, battery electrodes, etc., can solve the problems of material transport battery performance degradation, insufficient catalytic activity, large thickness of catalytic layer, etc., to achieve good catalytic activity, The effect of easy operation and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

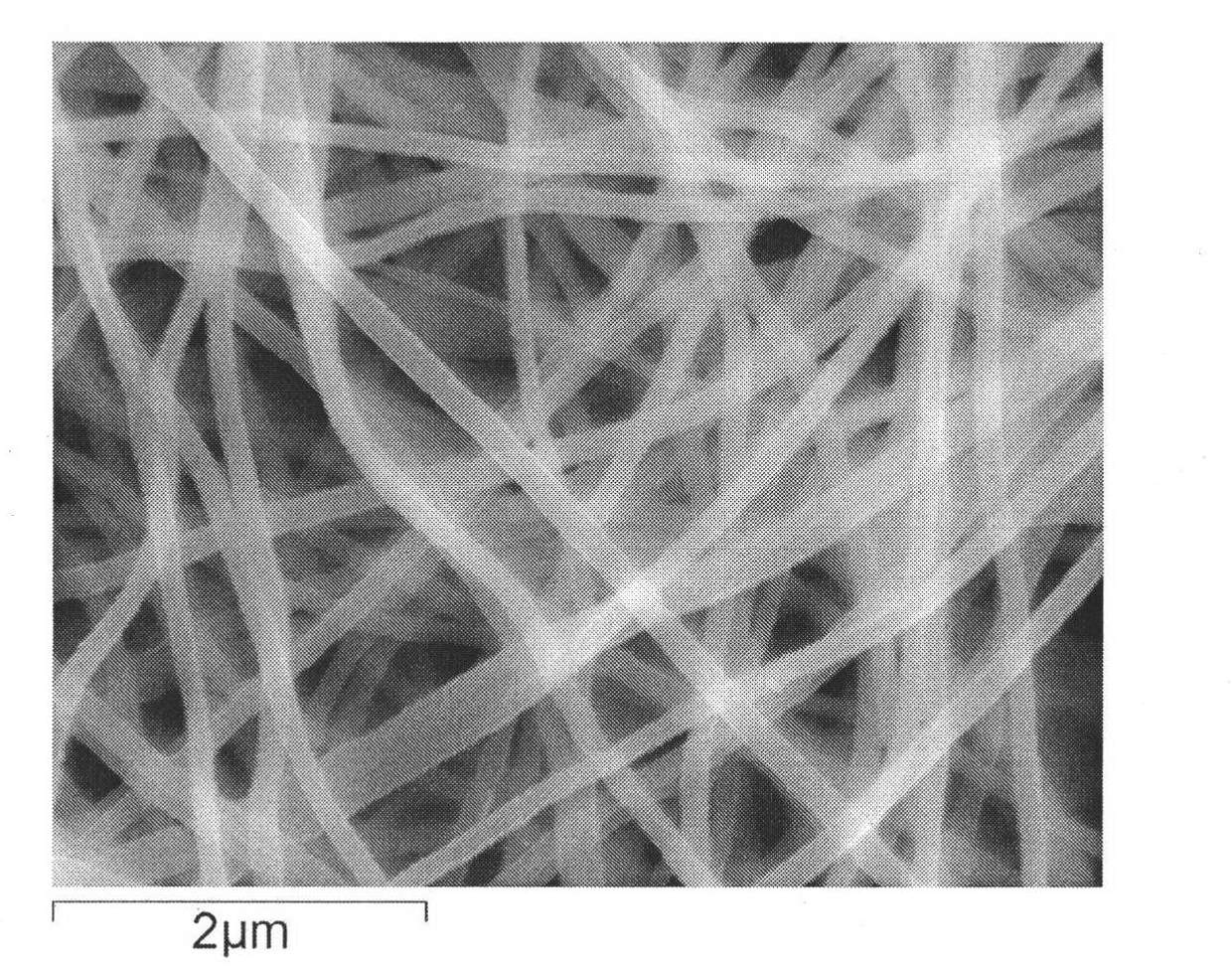

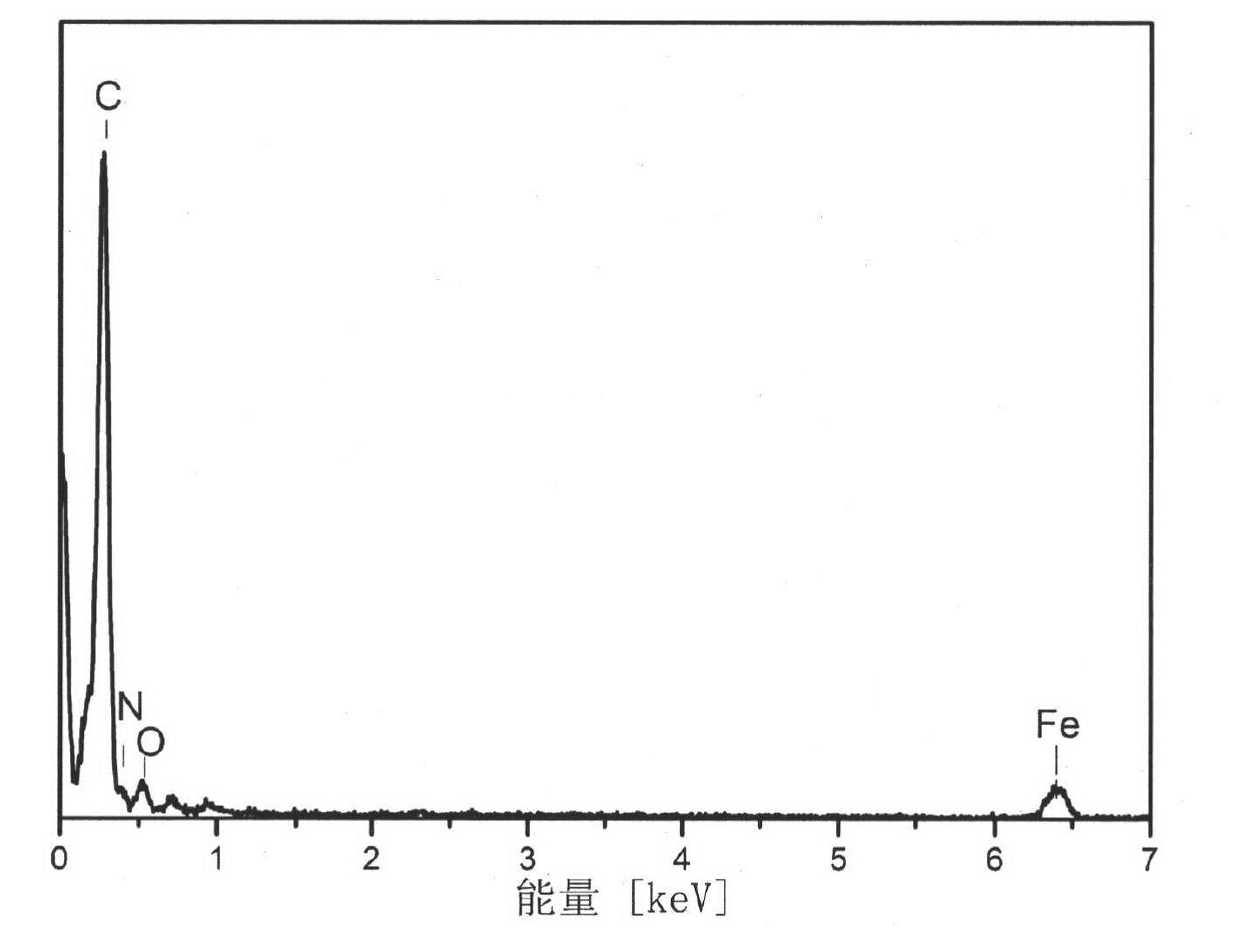

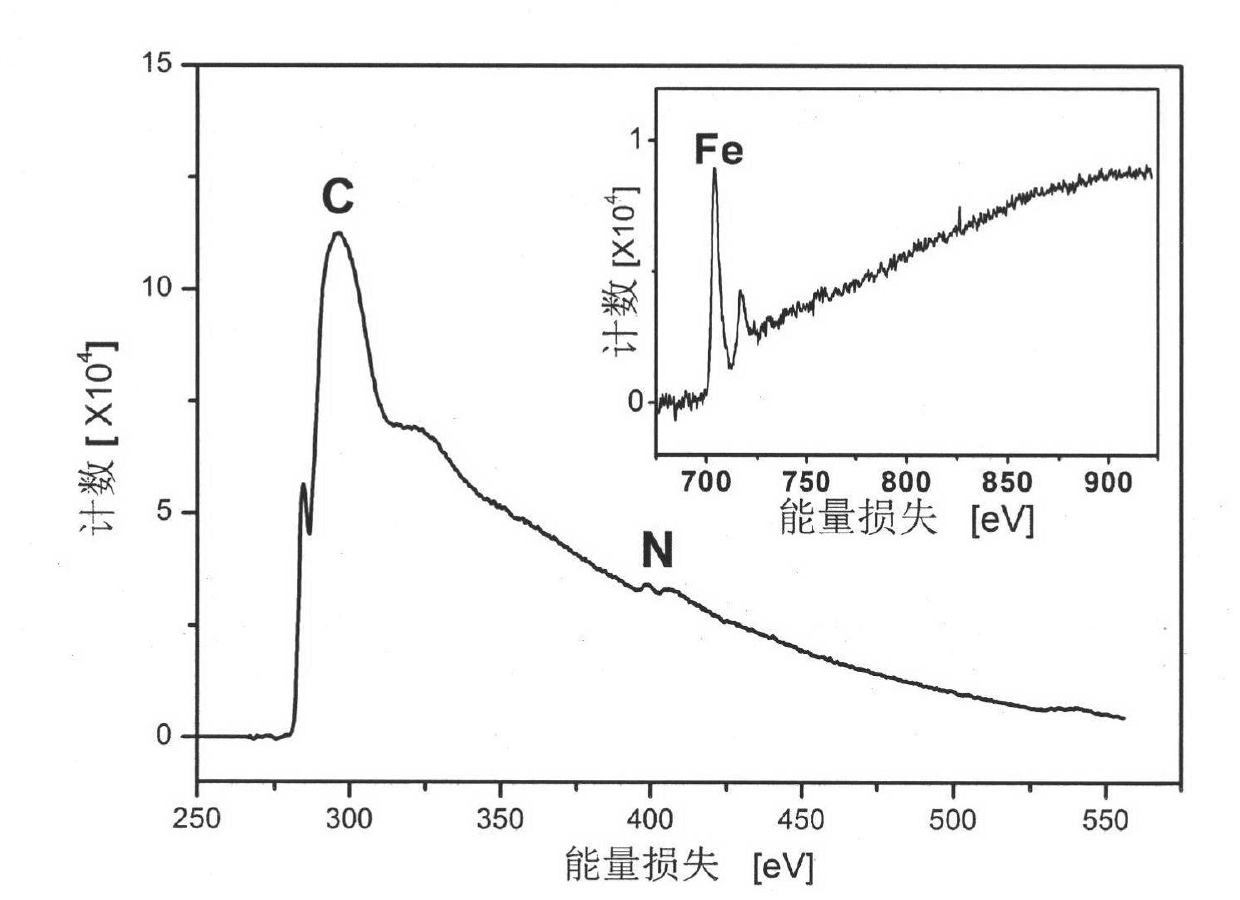

[0039] Example 1: Preparation of carbon nanofibers containing transition metals and nitrogen

[0040] Prepare the precursor solution: dissolve 0.2g of polyacrylonitrile in 3.8g of N-N-dimethylformamide (DMF) at 60°C, stir well to form a uniform and transparent solution, add 20mg of Fe(NO 3 ) 3 9H 2 O, continue stirring and dissolving at 60°C.

[0041] Spinning: Electrospinning is used to prepare nanofibers. The specific steps are: connect the prepared solution to a stainless steel needle through a catheter, and spray the solution through the needle at a flow rate of 0.4 mL / h. Carbon paper was used as the nanofiber collector, and the vertical distance from the needle was 15 cm, and it was grounded at the same time. Connect the needle tube to a high-voltage generator, adjust the voltage to 15kV, and start to obtain organic nanofibers on the collector. After one hour of spinning, organic nanofibers can be obtained.

[0042] Carbonization: Place organic nanofibers in a sealed...

example 2

[0044] Example 2: Magnesium nitrate is used as a template to prepare porous carbon nanofibers containing transition metals and nitrogen elements

[0045] Preparation of precursor solution: Dissolve 0.2 g of polyacrylonitrile in 3.8 g of N-N-dimethylformamide at 60° C. and stir well to form a uniform and transparent solution. Add 20mg of Fe(NO 3 ) 3 9H 2 O and 0.2g of Mg(NO 3 ) 2 4H 2 O, continue stirring and dissolving at 60°C.

[0046] Spinning: Electrospinning is used to prepare nanofibers. The specific steps are: connect the prepared solution to a stainless steel needle through a catheter, and spray the solution through the needle at a flow rate of 1.0 mL / h. Carbon paper was used as the nanofiber collector, and the vertical distance from the needle was 15 cm, and it was grounded at the same time. Connect the needle tube to a high-voltage generator, adjust the voltage to 30kV, and start to obtain organic nanofibers on the collector.

[0047] Carbonization: Place the ...

example 3

[0050] Example 3: Preparation of porous carbon nanofibers containing transition metals and nitrogen elements using silicon oxide as a template

[0051] Preparation of precursor solution: Dissolve 0.2 g of polyacrylonitrile in 3.8 g of N-N-dimethylformamide at 60° C. and stir well to form a uniform and transparent solution. Add 20mg of Fe(NO 3 ) 3 9H 2 O and 0..2g of silicon oxide nanoparticles (about 50nm in diameter), continue stirring and dissolving at 60°C.

[0052] Spinning: Electrospinning is used to prepare nanofibers. The specific steps are: connect the prepared solution to a stainless steel needle through a catheter, and spray the solution through the needle at a flow rate of 1.0 mL / h. Carbon paper was used as the nanofiber collector, and the vertical distance from the needle was 15 cm, and it was grounded at the same time. Connect the needle tube to a high-voltage generator, adjust the voltage to 30kV, and start to obtain organic nanofibers on the collector.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com