High-solid-content UV (Ultraviolet)-curing aqueous urethane acrylate dispersion liquid and preparation method thereof

A polyurethane acrylate, high solid content technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced active components of resin, increased consumption of photoinitiators, poor film formation and pinholes, etc., to achieve water The effect of reducing dosage, facilitating practical application, and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

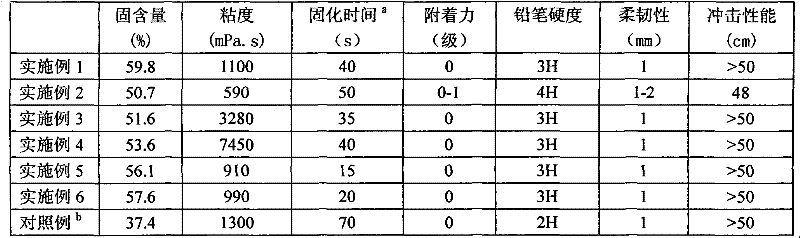

Examples

Embodiment 1

[0033] Add 10.05g Boltorn to a four-necked flask equipped with mechanical stirring, condenser, thermometer and nitrogen inlet H20 hyperbranched polyester and 10.03g tetrahydrofuran, after the hyperbranched polyester is dissolved, add 4.49g maleic anhydride and 0.05g monoesterification catalyst 4-dimethylaminopyridine, react in 50℃ oil bath for 10 hours Stop the reaction to obtain reaction intermediate I; add 10.18g isophorone diisocyanate and 0.01g dibutyl tin dilaurate to another reaction device, add 5.32g hydroxyethyl acrylate dropwise, and react at 70°C for 5h, The reaction intermediate II is obtained; the reaction intermediate I is added dropwise to the reaction intermediate II, 0.01 g of dibutyltin dilaurate is added, and the reaction is conducted at 80° C. for 6 hours to obtain the reaction intermediate III. After cooling to 30°C, 4.63g of triethylamine was added dropwise to neutralize with stirring for 30 minutes, then about 30g of deionized water was added to dilute, st...

Embodiment 2

[0035] Add 10.05g Boltorn to a four-necked flask equipped with mechanical stirring, condenser, thermometer and nitrogen inlet H20 hyperbranched polyester and 10.01g tetrahydrofuran, after the hyperbranched polyester is dissolved, add 10.15g phthalic anhydride and 0.05g monoesterification catalyst p-toluenesulfonic acid, react in 80℃ oil bath for 5 hours, then stop the reaction , Get reaction intermediate I; add 4.01g toluene diisocyanate, 0.01g dibutyl tin dilaurate, drop 2.96g hydroxyethyl methacrylate, and react at 50℃ for 3h to obtain reaction intermediate Body II: Add reaction intermediate I dropwise to reaction intermediate II, add 0.01 g of dibutyl tin dilaurate, and react at 60° C. for 4 hours to obtain reaction intermediate III. Then cool to 30°C, add 6.90g triethylamine dropwise under stirring to neutralize for 30 minutes, then add about 40g deionized water for dilution, stir at high speed for 40 minutes, distill under reduced pressure to remove tetrahydrofuran, and ob...

Embodiment 3

[0037] Add 10.05g Boltorn to a four-necked flask equipped with mechanical stirring, condenser, thermometer and nitrogen inlet H30 hyperbranched polyester and 12.20g tetrahydrofuran, after the hyperbranched polyester is dissolved, add 2.88g succinic anhydride and 0.07g monoesterification catalyst 4-dimethylaminopyridine, react in 30℃ oil bath for 12 hours and then stop the reaction , Get reaction intermediate I; add 14.41g hexahydrotoluene diisocyanate, 0.12g dibutyl tin dilaurate to another reaction device, drop 4.80g hydroxypropyl methacrylate, react at 55℃ for 3h to obtain Reaction Intermediate II: Add Reaction Intermediate I dropwise to Reaction Intermediate II, add 0.11 g of dibutyltin dilaurate, and react at 65°C for 6 hours to obtain Reaction Intermediate III. After cooling to 30°C, 11.13g of triethylamine was added dropwise to neutralize with stirring for 30 minutes, then about 40g of deionized water was added to dilute, stirred at high speed for 40 minutes, and tetrahyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com