Polyethylene/rubber expansion rubber brick for automobile and preparation method thereof

A technology of rubber expansion and polyethylene, which is applied in the field of expansion rubber blocks, can solve the problems of poor performance such as shock absorption, sound insulation and flame retardancy, complex preparation process of expansion rubber blocks, and discounted product performance, so as to achieve uniform product structure and low cost. Low, good filling and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

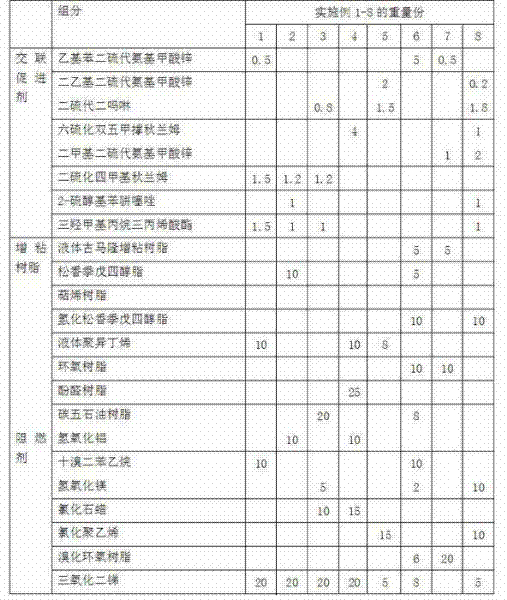

Examples

Embodiment 1

[0022] (1) Internal mixing: In terms of parts by weight, first add 60 parts of low-density polyethylene, 40 parts of medium-density polyethylene, and 20 parts of natural rubber into the internal mixer, mix at 120°C for 10 minutes, and then Add 15 parts of 4,4'-oxobisbenzenesulfonyl hydrazide, 5 parts of polyethylene wax, 1.5 parts of zinc stearate, 1 part of dicumyl peroxide, 0.2 parts of sulfur, triallyl 3 parts of isocyanurate, 1.5 parts of tetramethylthiuram disulfide, 0.5 parts of zinc ethylbenzene dithiocarbamate, 1.5 parts of trimethylolpropane triacrylate, 10 parts of liquid polyisobutylene, trioxide 20 parts of diantimony and 10 parts of decabromodiphenylethane were mixed for another 5 minutes at a temperature of 110° C. to form a uniform mixture.

[0023] (2) Milling: Add the above-mentioned homogeneous mixture into a two-roller kneader, pass it thinly for 5 times at a temperature of 120°C, and produce tablets, then pulverize and granulate into pellets with a pulveriz...

Embodiment 2

[0027] (1) Internal mixing: In terms of parts by weight, first add 80 parts of low-density polyethylene, 20 parts of medium-density polyethylene, and 15 parts of ethylene-propylene rubber into the internal mixer, and mix for 15 minutes at a temperature of 135°C. Then add 10 parts of azodicarbonamide, 10 parts of azobisisobutyronitrile, 4 parts of foaming aid AG-210, 1.5 parts of calcium silicate, 1 part of tert-butyl dicumyl peroxide, and 0.3 parts of sulfur 1 part, 3 parts of triallyl isocyanurate, 1.2 parts of tetramethylthiuram disulfide, 1 part of 2-mercaptobenzothiazole, 1 part of trimethylolpropane triacrylate, rosin pentaerythritol ester 10 parts, 20 parts of antimony trioxide, 10 parts of aluminum hydroxide, and mixed at 125 ° C for 8 minutes to form a uniform mixture.

[0028] (2) Kneading: Add the above-mentioned homogeneous mixture into a two-roller kneader, pass it thinly for 8 times at a temperature of 135°C, and then produce tablets, then pulverize and granulate ...

Embodiment 3

[0032] (1) Internal mixing: in parts by weight, first add 90 parts of low-density polyethylene, 10 parts of medium-density polyethylene, and 25 parts of styrene-butadiene rubber into the internal mixer, and mix for 20 minutes at a temperature of 110°C. Then add 20 parts of N,N-dinitrosopentamethylenetetramine, 5 parts of ammonium bicarbonate, 4 parts of white oil, 1 part of urea, 2,5-dimethyl-2,5-bis(tert 1.5 parts of butyl peroxy) hexane, 0.4 parts of sulfur, 3 parts of triallyl isocyanurate, 1.2 parts of tetramethylthiuram disulfide, 0.8 parts of dithiodimorpholine, trimethylol 1 part of propane triacrylate, 20 parts of C5 petroleum resin, 20 parts of antimony trioxide, 5 parts of magnesium hydroxide, and 10 parts of chlorinated paraffin, and mixed at 105°C for 20 minutes to form a uniform mixture.

[0033] (2) Kneading: Add the above mixture into a two-roller kneader, pass it thinly for 12 times at a temperature of 115°C, and produce tablets, then pulverize and granulate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com