Modified vitrified micro bubble composition and preparation method thereof

A technology of vitrified microbeads and compositions, applied in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve problems such as high water absorption, poor compatibility between vitrified microbeads and adhesives, and influence on mortar, etc. , to achieve the effect of reducing shrinkage, excellent hydrophilicity, and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment (sample) 1

[0020] Vitrified microbeads (bulk density 53.1Kg / m 3 ) 100 parts, stearic acid 1 part, dimethyl silicone oil 3 parts, silane coupling agent 1 part, oleic acid amide 0.5 parts, zinc sulfide 1 part, silica powder 5 parts

[0021] It is prepared by the following method: in an overturning mixing reaction kettle (LC-1 dry type electric heating mixer, manufactured by Dongguan Licai Hardware Plastic Products Co., Ltd.), add 100 parts of vitrified microbeads, and heat to make the temperature of vitrified microbeads reach At 75°C, heat the stearic acid to a molten state, and then spray it on the vitrified microbeads; after mixing for 15 minutes, spray simethicone; after mixing for 15 minutes, spray the coupling agent; mix for 15 minutes Finally, spray oleic acid amide; after 15 minutes of inversion and mixing, add zinc sulfide and active silica powder, and inversion and mixing for 30 minutes.

[0022] Embodiment (sample) 2

[0023] Vitrified microbeads...

Embodiment 7

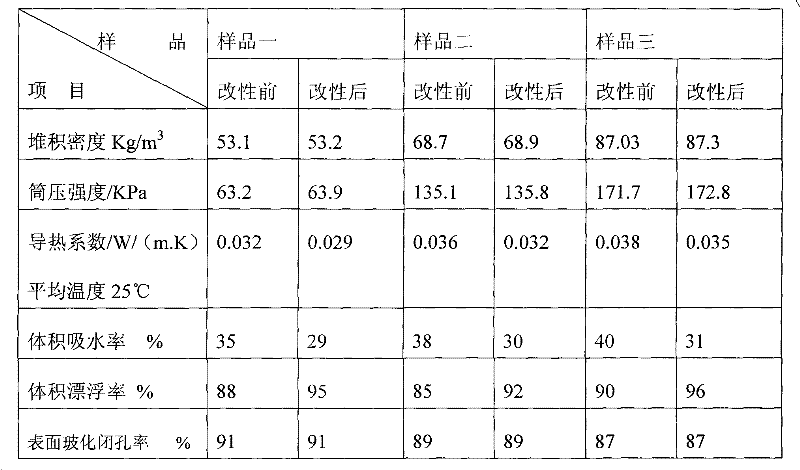

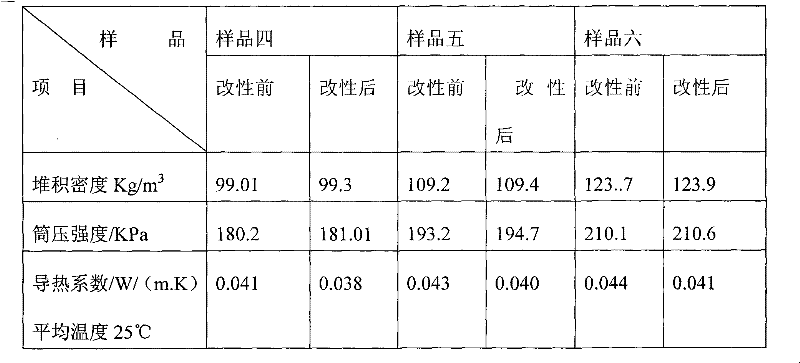

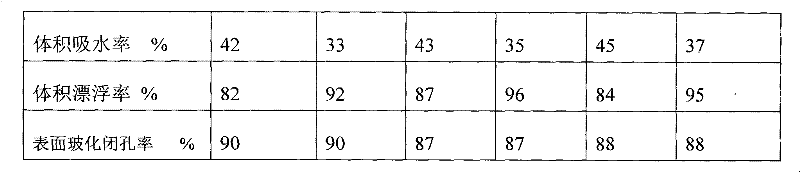

[0038] 1. The mechanical test of vitrified microbeads before and after modification was carried out according to the method specified in the national building materials industry standard (JC / T 1042-2007 expanded vitrified microbeads). The results are shown in Table 1.

[0039] Table 1

[0040]

[0041] Continued Table 1

[0042]

[0043]

[0044] 2. Application and test method of vitrified microbeads in thermal insulation mortar (components are parts by weight)

[0045] 1. Thermal insulation mortar formula: 46 parts of ordinary Portland cement, 50 parts of vitrified microbeads (modified), 3 parts of redispersible latex powder, 0.2 parts of cellulose ether (40,000 molecular weight), 0.05 parts of 3mmPP fiber, glucose 0.2 parts of sodium phosphate, 0.15 parts of starch ether, 0.2 parts of melamine superplasticizer, 0.2 parts of lignin, and 10 parts of water.

[0046]2. Test method: "Technical Regulations for Application of Vitrified Bead Thermal Insulation Mortar", DB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com