Wet process for treating lead copper matte

A wet processing, lead matte technology, applied in the direction of improving process efficiency, can solve problems such as inconvenience of operation, achieve the effects of convenient operation, improve metal leaching rate, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

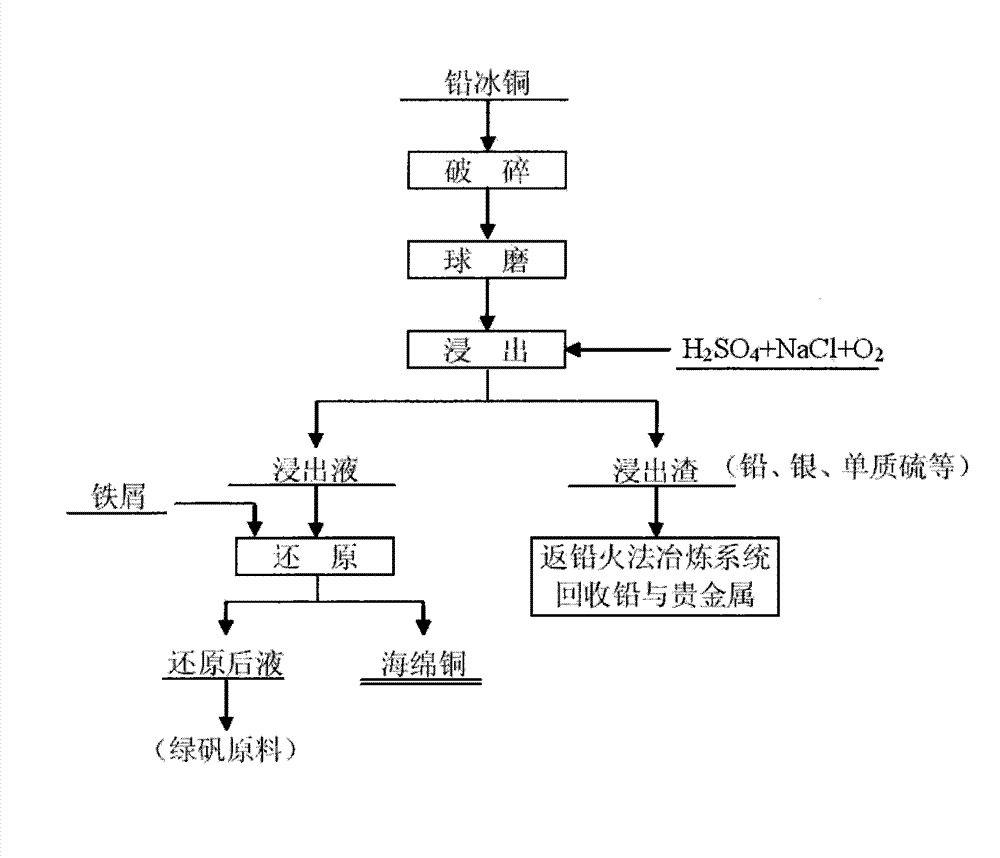

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Break the lead matte block material, ball mill it until the particle size is less than 50 mesh, leaching with dilute sulfuric acid solution and sodium chloride, continuously feed pure oxygen during the leaching process, and oxidize and leaching copper. The leaching conditions: sulfuric acid concentration 1.2 mol / L, sodium chloride concentration 0.25mol / L, liquid-solid ratio 9:1, temperature 90°C, time 5h; oxygen flow rate 700mL / min. The copper leaching rate is 97.5%, while the lead remains in the slag in the form of lead sulfate and lead chloride; the leaching solution is reduced with iron filings, and the reduction conditions are: pH=1, room temperature, 1.5 times the theoretical amount of iron filings, and time 2h . The copper reduction rate is 97%, and the purity of the obtained sponge copper is 90%.

Embodiment 2

[0015] Example 2: Break the lead matte block material, ball mill it until the particle size is less than 60 mesh, leaching with dilute sulfuric acid solution and sodium chloride, continuously feed pure oxygen during the leaching process, and oxidize and leaching copper. The leaching conditions: sulfuric acid concentration 0.9 mol / L, sodium chloride concentration 0.5mol / L, liquid-solid ratio 6:1, temperature 95°C, time 3h, oxygen flow rate 600mL / min. The leaching rate of copper is 98.5%, while the lead remains in the slag in the form of lead sulfate and lead chloride; the leaching solution is reduced with iron filings, and the reduction conditions are: pH=2, room temperature, 1.8 times the theoretical amount of iron filings, and time 3h . The copper reduction rate is 97.5%, and the purity of the obtained sponge copper is 90.2%.

Embodiment 3

[0016] Example 3: Break the lead matte block material, ball mill it until the particle size is less than 50 mesh, leaching with dilute sulfuric acid solution and sodium chloride, continuously feed pure oxygen during the leaching process, and oxidize and leaching copper. The leaching conditions: sulfuric acid concentration 1.1 mol / L, sodium chloride concentration 1.0mol / L, liquid-solid ratio 8:1, temperature 85°C, time 4 h, the oxygen flow rate is 800mL / min. The leaching rate of copper is 98.5%, while the lead remains in the slag in the form of lead sulfate and lead chloride; the leaching solution is reduced with iron filings, and the reduction conditions are: pH=1, room temperature, twice the theoretical amount of iron filings, and time 2h . The copper reduction rate is 99.2%, and the purity of the obtained sponge copper is 90.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com