Method for preparing Re:YAG polycrystalline transparent ceramic by using different molding modes

A polycrystalline transparent, ceramic technology, applied in the field of special optical ceramics manufacturing process, can solve the problems of long growth period, difficult to increase crystal size and doping concentration, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

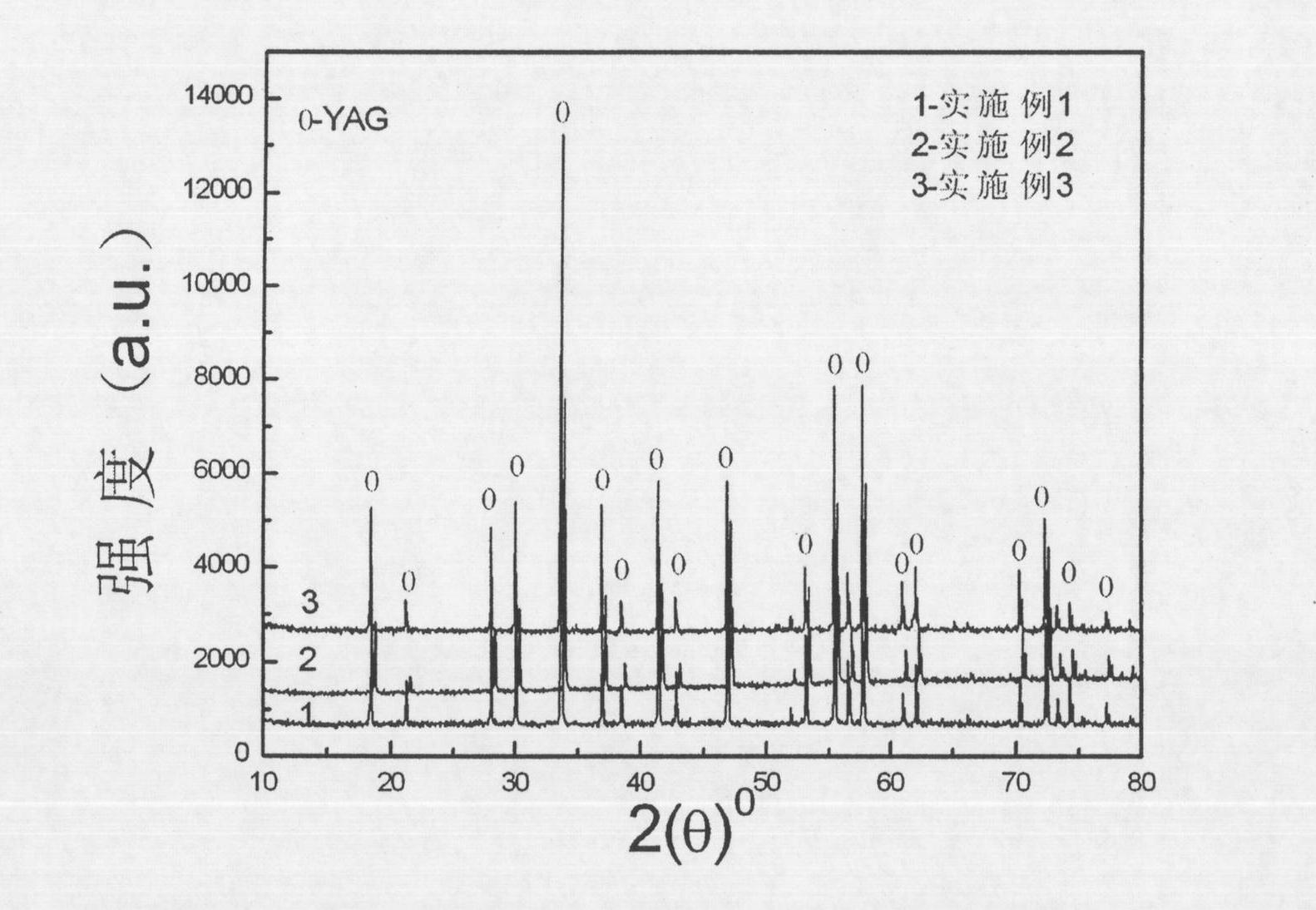

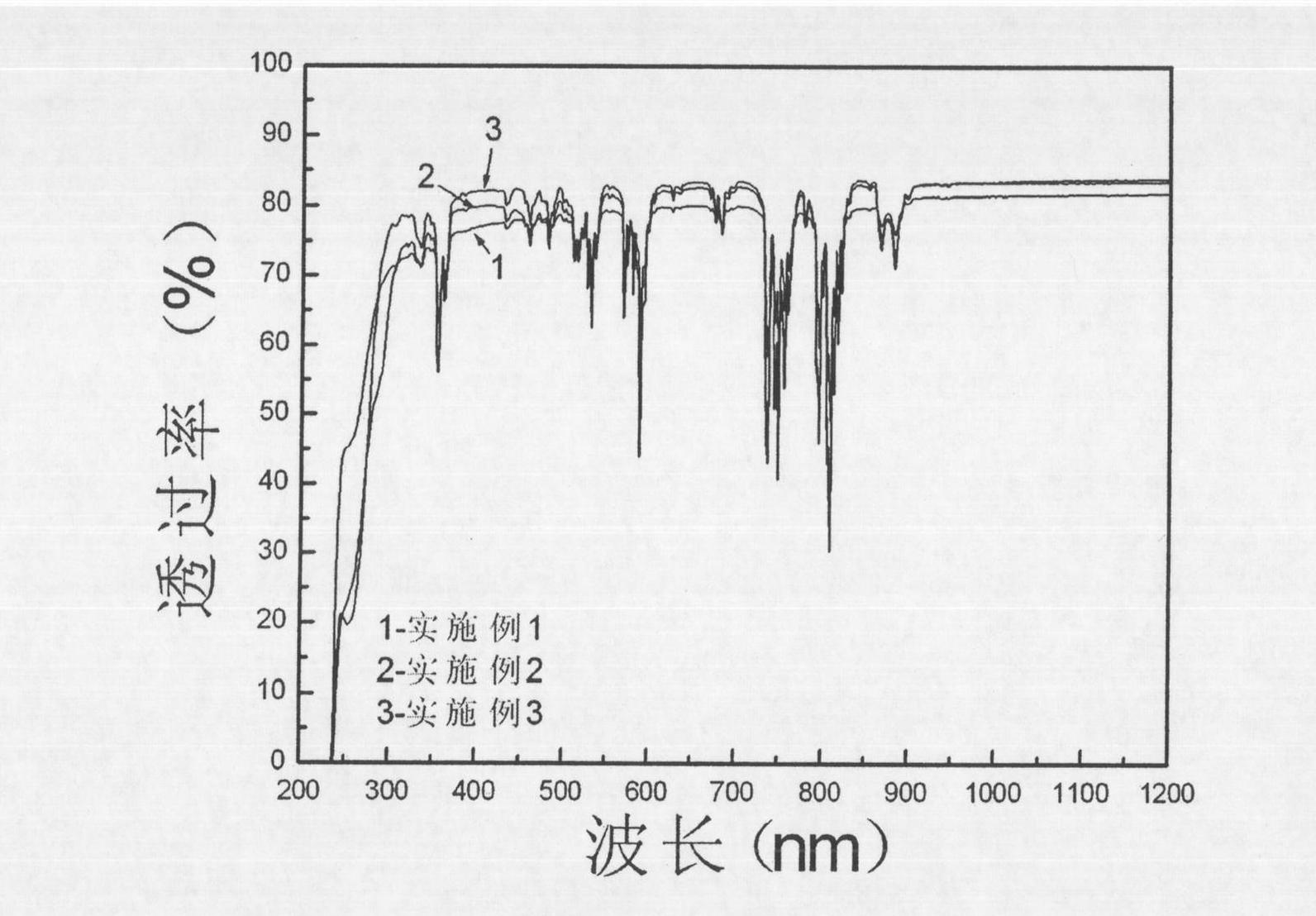

Examples

Embodiment 1

[0017]Put 5.098g of α-Al2O3 powder, 6.7066g of Y2O3 powder, 0.1010g of Nd2O3, 0.0600g of TEOS and 0.0600g of castor oil, 0.3600g of PVB, and 0.1200g of unsaturated fatty acid into a high-purity agate ball mill jar , add 72g of high-purity agate balls, 11.800g of absolute ethanol, mix ball mill for 24h. After ball milling, the slurry was dried in an oven at 80°C, and after drying for 48 hours, it was put into an agate mortar and ground, and the powder was passed through a 200-mesh sieve. Axial one-way pressurization with a pressure of 2-10Mpa to form a Φ15 disc, and then cold isostatic pressing under a pressure of 200Mpa. Put the isostatically pressed green body into a tube furnace and raise the temperature to 700°C at a rate of 1°C / min under an oxygen atmosphere, keep it warm for 2 hours, and the oxygen flow rate is 50-100ml per minute, and cool naturally after the keep warm. The degreased green body is put into a vacuum furnace, and the vacuum degree is 1.5×10 -4 Carry out ...

Embodiment 2

[0019] Weigh the commercially available high-purity powder according to the stoichiometric ratio: Y 2 o 3 : 10.0600g, Al 2 o 3 : 7.6470g, Nd 2 o 3 : 0.1516g, add 0.5at% MgO sintering aid, 0.2wt% dispersant polycarboxylic acid, 0.2wt% binder polyvinyl alcohol, 0.5wt% defoamer n-butanol; Additives were poured into 100 g of deionized water and ball milled for 12 hours and mixed at a ball milling speed of 350 r / m, material: ball = 1:10. Put the slurry mixed by ball milling into a vacuum tank, vacuum treatment until the vacuum degree reaches below -0.1Mpa, and no air bubbles escape from the slurry; inject the slurry after defoaming into the gypsum mold, and wait for the gypsum mold to absorb the slurry , the green body shrinks and the plaster mold is separated, and the mold is removed. The formed green body is first dried in the shade at room temperature for a period of time, and then put into an oven to keep warm at 30°C for 5 hours, 40°C for 3 hours, 60°C for 2 hours, and s...

Embodiment 3

[0021] Weigh the commercially available high-purity powder according to the stoichiometric ratio: Y 2 o 3 : 10.0600g, Al 2 o 3 : 7.6470g, Nd 2 o 3 : 0.1516g, add the MgO sintering aid of 0.5at%, add 0.06wt% dispersant fish oil, add raw material to 60 grams by dehydrated alcohol and xylene in the mixed solvent, material: ball=1: 5, ball mill mixes 5 After ~24 hours, add 10wt% binder polyvinyl butyral to the homogeneously mixed slurry, 5wt% plasticizer is butyl phthalate and 1wt% polyalkylene glycol, 0.5wt% except The foaming agent octanol is then mixed and ball milled for 5 to 24 hours. Put the ball-milled slurry into a vacuum defoaming machine, and stir it under negative pressure until no air bubbles escape from the slurry. Pour the defoamed slurry into the hopper of the casting machine, turn on the mechanical motor, rotate the film belt at a constant speed, spread it evenly on the film belt with a scraper, heat the bottom plate to a suitable temperature and dry the gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com