Non-halogen fire resistant low-temperature shrinkable and heat-shrinkable pipe material and preparation method thereof

A technology of low-temperature shrinkage and heat-shrinkable tubing, which is applied in pipeline protection, mechanical equipment, pipeline anticorrosion/rust protection, etc. It can solve the problems of poor flame retardancy and high heat shrinkage response temperature, and achieves low price, simple method, Good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

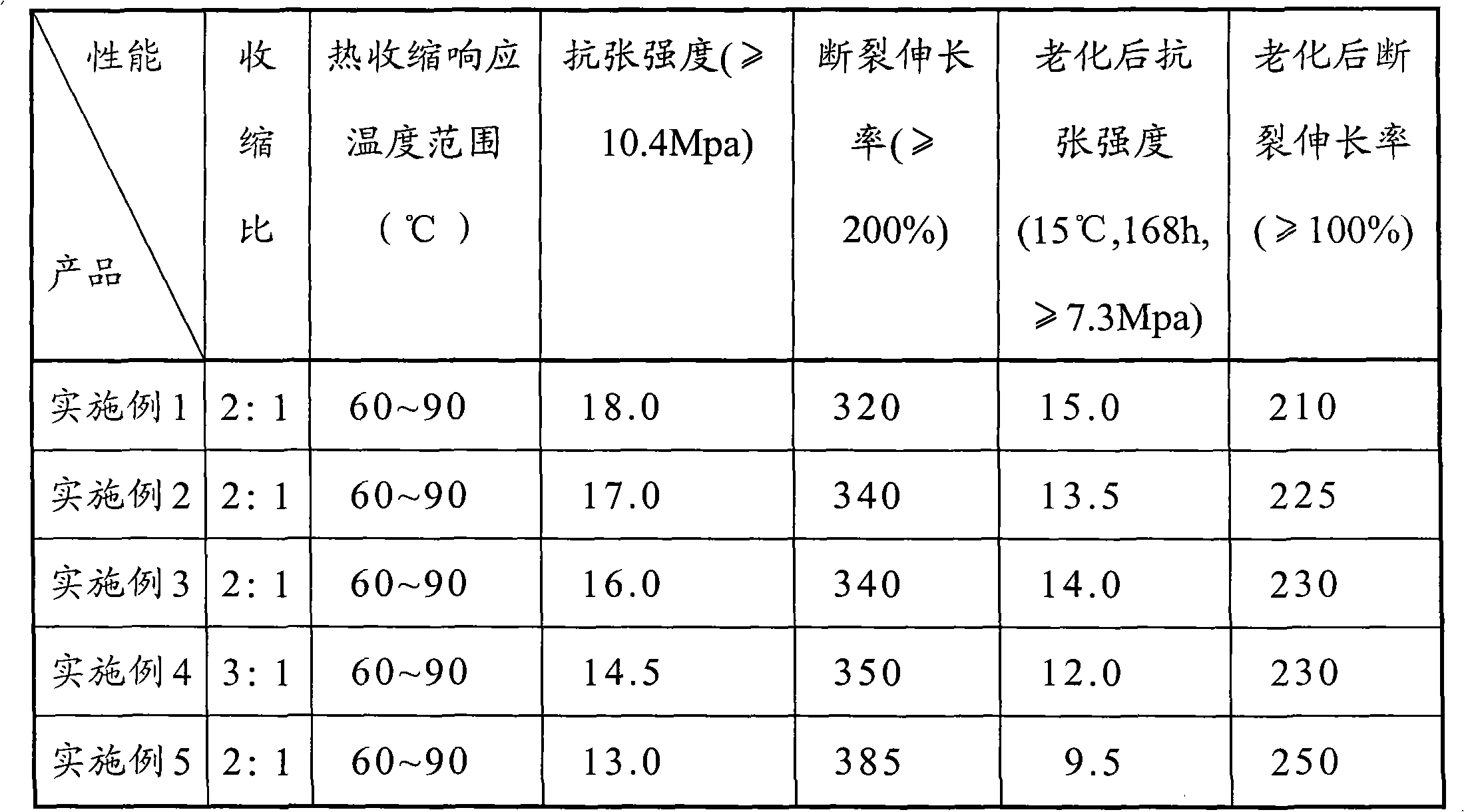

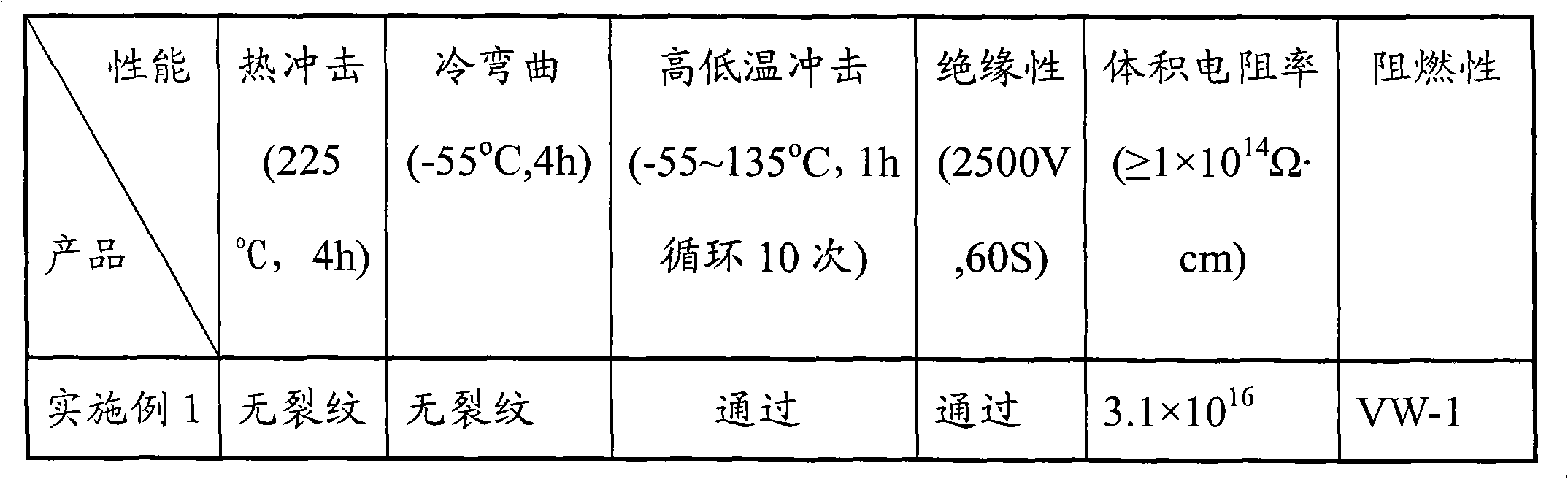

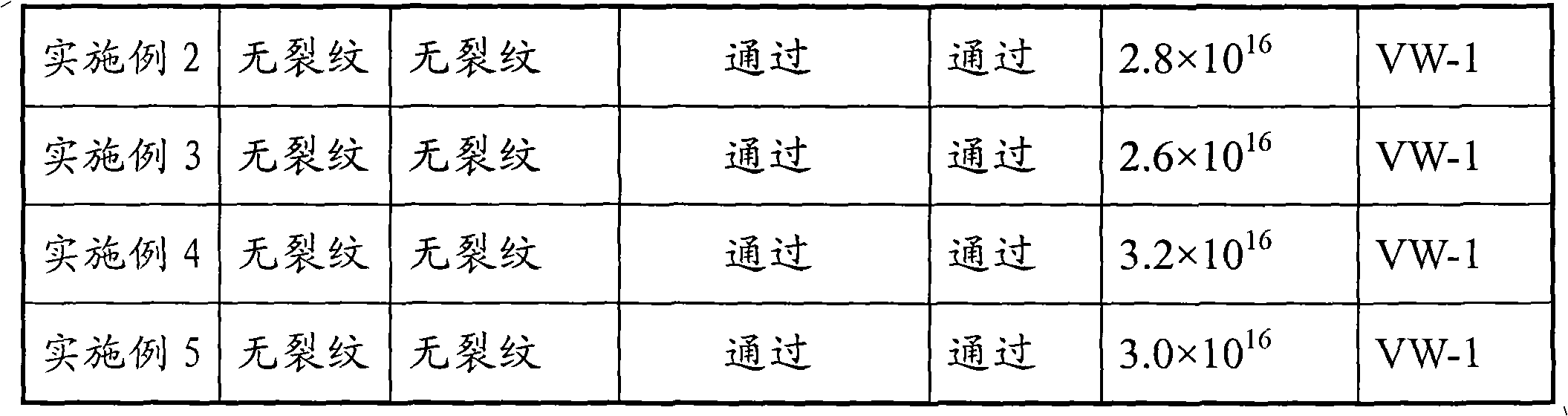

Examples

Embodiment 1

[0043] Prepare according to the following recipe:

[0044] 100 parts of ethylene-vinyl acetate copolymer (EVA);

[0045] 30 parts of ammonium polyphosphate coated with melamine resin;

[0046] 10 parts of red phosphorus coated with phenolic resin;

[0047] 8 parts of zinc borate;

[0048] 30 parts of superfine magnesium hydroxide powders treated with surface activation;

[0049] 2 parts of compatibilizer;

[0050] Main antioxidant pentaerythritol ester (antioxidant 1010) 0.5 part;

[0051] Secondary Antioxidant Dilauryl Thiodipropionate

[0052] 0.5 copies;

[0053] (DLTP)

[0054] Lubricant calcium stearate 1 part;

[0055] Lubricant polyethylene wax 1.5 parts;

[0056] 2 parts of sensitizer triallyl isocyanate (TAIC);

[0057] 5 parts of black masterbatch,

[0058] Wherein, the melt index MI of the ethylene-vinyl acetate copolymer (EVA) is 3.6g / 10min, and the weight percentage of vinyl acetate in the copolymer is 14%, and the partic...

Embodiment 2

[0063] Prepare according to the following recipe:

[0064] 100 parts of ethylene-vinyl acetate copolymer (EVA);

[0065] 35 parts of ammonium polyphosphate coated with melamine resin;

[0066] 8 parts of red phosphorus coated with phenolic resin;

[0067] 8 parts of zinc borate;

[0068] 25 parts of superfine magnesium hydroxide powders treated with surface activation;

[0069] 1.5 parts of compatibilizer;

[0070] Main antioxidant pentaerythritol ester (antioxidant 1010) 0.5 part;

[0071] Secondary Antioxidant Dilauryl Thiodipropionate

[0072] 1 copy;

[0073] (DLTP)

[0074] 1.5 parts of lubricant polyethylene wax 1.5 parts;

[0075] 2 parts of sensitizer triallyl isocyanate (TAIC);

[0076] 4 parts of black masterbatch,

[0077] Wherein, the melt index MI of the ethylene-vinyl acetate copolymer (EVA) is 3.6g / 10min, and the weight percentage of vinyl acetate in the copolymer is 14%, and the particle size of the phenolic resin coa...

Embodiment 3

[0082] Prepare according to the following recipe:

[0083] 100 parts of ethylene-vinyl acetate copolymer (EVA);

[0084] 35 parts of ammonium polyphosphate coated with melamine resin;

[0085] 15 parts of red phosphorus coated with phenolic resin;

[0086] 5 parts of zinc borate;

[0087] 20 parts of surface-activated superfine magnesium hydroxide powder;

[0088] 4 parts of compatibilizer;

[0089] Main antioxidant pentaerythritol ester (antioxidant 1010) 0.5 part;

[0090] Secondary Antioxidant Dilauryl Thiodipropionate

[0091] 0.5 copies;

[0092] (DLTP)

[0093] Lubricant calcium stearate 1.5 parts;

[0094] Lubricant polyethylene wax 1 part;

[0095] 2 parts of sensitizer pentaerythritol tetraacrylate (PETEA);

[0096] 4 parts of black masterbatch,

[0097] Wherein, the melt index MI of the ethylene-vinyl acetate copolymer (EVA) is 1.5g / 10min, and the weight percent of vinyl acetate in the copolymer is 15%, and the particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com