Production method of recombinant multifunctional cellulase

A cellulase, multifunctional technology, applied in the field of production of multifunctional cellulase, can solve the problems of high production cost, single component, complex cellulase production process, etc., and achieve the effect of difficult purification and low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare medium:

[0033] PDSA medium: Potato (peeled) 200g, glucose 20g, dipotassium hydrogen phosphate 3g, magnesium sulfate 1.5g, glucose 20g, agar 20g, distilled water to 1000mL, autoclaved for later use.

[0034] PDSB medium: no agar is added to the PDSA medium, and it is used after autoclaving.

[0035] Basic enzyme production medium: carbon source 20g, nitrogen source 4g, dipotassium hydrogen phosphate 1g, potassium dihydrogen phosphate 0.46g, magnesium sulfate 1g, adjust the initial pH to 5.5, distilled water to 1000ml, high temperature sterilization.

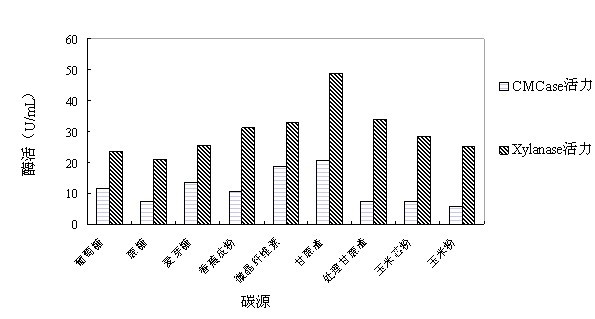

[0036] Comparison of various production methods of recombinant multifunctional cellulase:

[0037] (1) According to Zhao Shuxian's master's thesis (multifunctional cellulase gene mfc Research on genetic transformation of Tremella spores, master thesis of South China Agricultural University, June 2008) to construct and obtain Tremella spore engineering strain ycLes3, inoculate it on a PDSA plate at 25°C for 4-5 d...

Embodiment 2

[0045] (1) Inoculate the ycLes3 strain prepared in Example 1 on a PDSA plate, incubate at 25°C for 4 days, pick a single colony and inoculate it in 100 mL of PDSB liquid medium, inoculate at 25°C, 180r / min shaking for 72h;

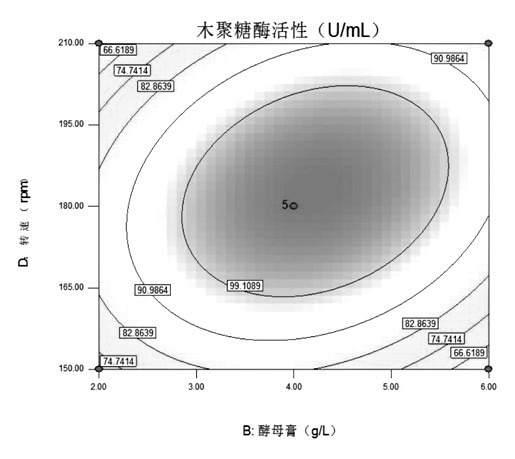

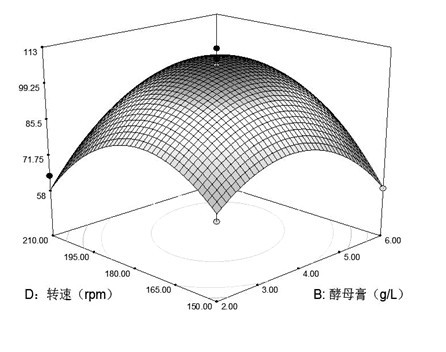

[0046] (2) Prepare bagasse medium, bagasse powder 20.31g / L, yeast extract 4.11 g / L, dipotassium hydrogen phosphate 1g / L, potassium dihydrogen phosphate 0.46g / L, magnesium sulfate 1g / L, adjust the pH value 5.5; Divide into 250mL Erlenmeyer flasks, each bottle contains 100mL, and autoclave;

[0047] (3) In the ultra-clean work, each bottle was inoculated with 1mL of the bacteria cultured in step (1), and placed on a shaking table at 25°C after inoculation, and the shaking table speed was 180r / min.

[0048] (4) Terminate the culture after 4 days of culture, and collect the fermentation broth by centrifugation.

[0049] The PDSA solid medium formula wherein consists of the following parts by weight: 200 parts of potatoes, 20 parts of glucose, 3 parts of dipot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com