Method for using transgenic Coprinus cinereus to efficiently express recombinant enzyme

A high-efficiency expression, gray-covered ghost technology, applied in the direction of recombinant DNA technology, biochemical equipment and methods, enzymes, etc., can solve the problems of high production cost, single component, inability to effectively degrade cellulose, etc., to achieve difficult purification, active low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare medium:

[0033] Seed medium: microcrystalline cellulose 20g, yeast extract 4g, dipotassium hydrogen phosphate 1g, potassium dihydrogen phosphate 0.46g, magnesium sulfate 1g, distilled water to 1000mL, autoclaved for later use.

[0034] Coprinus cinereus solid medium: glucose 10 g, asparagine 2 g, adenine sulfate 0.1 g, Stock A buffer 25 mL, Stock B buffer 1 mL, Stock C buffer 10 mL, agar 14 g, Distilled water to make up to 1000mL, autoclaved for later use.

[0035] Stock A buffer: ammonium tartrate 20 g, KH 2 PO 4 40 g, anhydrous NaSO 4 11.6 g, anhydrous Na 2 HPO 4 90 g, distilled water to 1000mL, add a few drops of chloroform and store at room temperature.

[0036] Stock B buffer solution: 0.04 g of thiamine, distilled water to 1000 mL, stored at 4°C after filter sterilization.

[0037] Stock C buffer: MgCl 2 ·H 2 O 25 g, distilled water to 1000 mL, autoclave, room temperature

[0038] Save it.

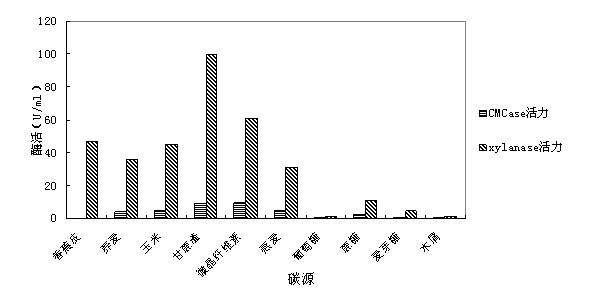

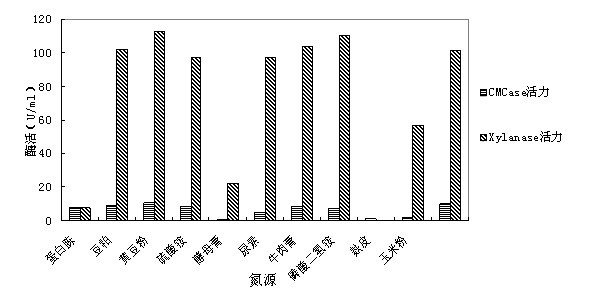

[0039] Basic enzyme production medium: carbon source ...

Embodiment 2

[0049] (1) Inoculate the TCles11 strain prepared in Example 1 on the Coprinus cinereus solid medium plate, culture at 37°C for 7 days, inoculate 1-5% into 100mL seed medium, and culture at 37°C for 96 hours with shaking at 210r / min;

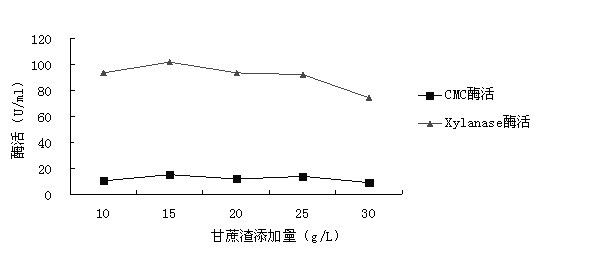

[0050] (2) Prepare the intermixing medium of bagasse and soybean meal, bagasse powder 30g / L, soybean meal 6 g / L, dipotassium hydrogen phosphate 1g / L, potassium dihydrogen phosphate 0.46g / L, magnesium sulfate 1g / L , adjust the pH value to 6.25; divide into 250mL Erlenmeyer flasks, each bottle contains 100mL, and sterilize under high pressure;

[0051] (3) In the ultra-clean work, inoculate each bottle with 1mL of the bacteria cultured in step (1), and place it on a shaking table at 37°C after inoculation, and the shaking table speed is 210r / min.

[0052] (4) The culture was terminated after 7 days of cultivation, and the fermentation broth was collected by centrifugation.

[0053] The formula of the Coprinus cinereus solid medium is composed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com