Method for preparing lignin sulfonate dye dispersant

A lignosulfonate and dye dispersant technology, applied in the direction of organic dyes, can solve the problems of dispersion performance change, long production cycle, poor heat resistance stability, etc., achieve good heat resistance stability and high temperature dispersion performance, enhance Adsorption capacity, effect of increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Using pine as raw material, white pine, red pine, etc. as ingredients, using calcium bisulfite as cooking liquid to pulp the waste liquid, in which the content of calcium lignosulfonate is 60%, and the content of reducing sugar is 20% , other impurity content is 10%; Adopt five-effect evaporator to concentrate described waste liquid, obtain the concentrated liquid that solid content is 35%, specific gravity is about 1.10; Add 150 kilograms of sodium hydroxide in 2857kg waste liquid, obtain The pH value of the solution is about 6.3, the temperature of the obtained solution is raised to 90° C., the air is passed through to carry out the hypoglycemic reaction, and the reaction is carried out for 2 hours to obtain the first solution, wherein the reducing sugar content is reduced to 1%;

[0081] Add 240kg of light sodium carbonate to the first solution, carry out a displacement reaction at a temperature of 80°C to 90°C, and react for 40min to 60min; filter the solution with a...

Embodiment 2

[0083] Add 1 mol of β-methylnaphthalene to 1 mol of concentrated sulfuric acid, heat up to 160°C for sulfonation for 120 minutes, dissolve the obtained sulfonated product in water, cool down to 120°C, add 1 mol of formaldehyde, and condense for 120 minutes to obtain methylnaphthalenesulfonic acid formaldehyde condensation thing;

[0084] Add 1040g of the sodium lignosulfonate solution prepared in Example 1 to a 2000mL reaction flask, heat up to 75°C while stirring, add 0.624mol of formaldehyde to react for 120min, and then add 200g of the above-prepared methylsulfonate naphthaldehyde condensate, Raise the temperature to 100°C and react for 240 minutes, then add activated carbon to it for adsorption for 20 minutes, centrifuge the solution, filter, and spray dry to obtain a lignosulfonate dye dispersant, the pH value of the lignosulfonate dye dispersant is is 9.5.

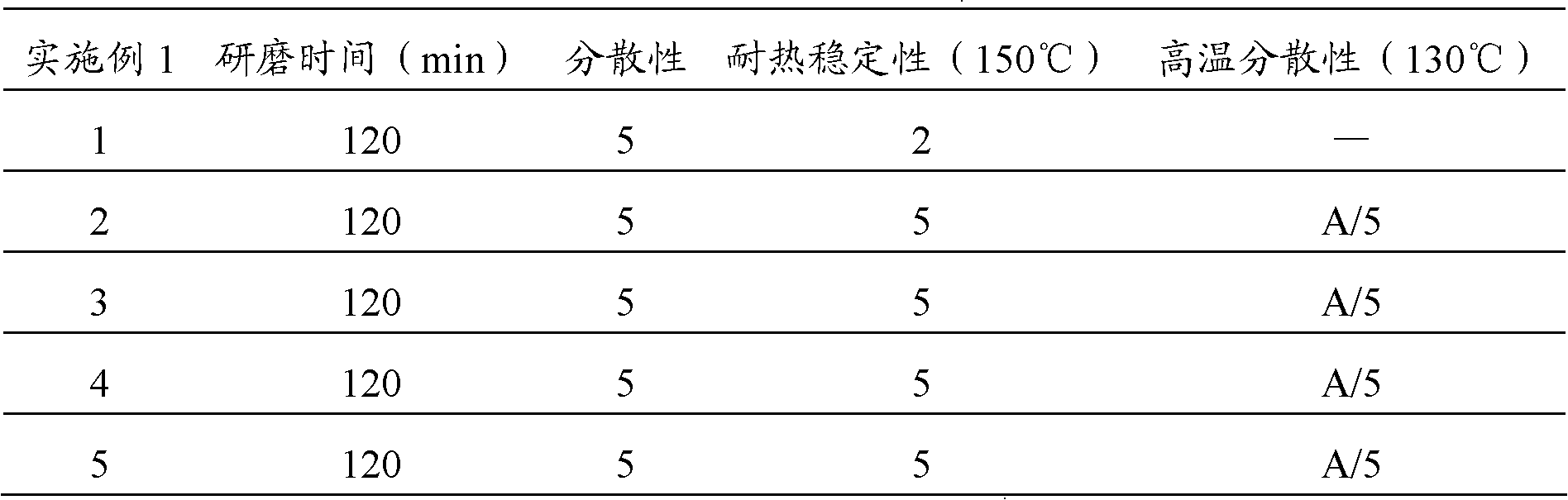

[0085] According to the method described above, the performance test of the lignosulfonate dye dispersant, the re...

Embodiment 3

[0087] Add 1040g of the sodium lignosulfonate solution prepared in Example 1 into a 2L small autoclave, heat up to 75°C under stirring, then add 50g of 2-naphthol, 50g of benzyl alcohol and 0.832mol of formaldehyde, continue to heat up to 140°C for 1 hour , and then add activated carbon to it for adsorption for 20min, centrifuge the solution, filter and spray dry to obtain a lignosulfonate dye dispersant, and the pH value of the lignosulfonate dye dispersant is 9.3.

[0088] According to the method described above, the performance test of the lignosulfonate dye dispersant, the results show that the dispersant performance of the lignosulfonate dye dispersant can reach grade 5. It has good heat resistance and stability, and it has good high-temperature dispersion performance at 130 ° C. It basically does not stain fibers, and its reducibility to azo dyes is also weak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com