Method for quickly accumulating grease through mixotrophic sterile culture of microalgae

A mixed nutrition and heterotrophic culture technology, applied in the direction of microorganism-based methods, fat oil/fat production, biochemical equipment and methods, etc., can solve the problems of high cost, easy to infect bacteria, and inability to completely remove other miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

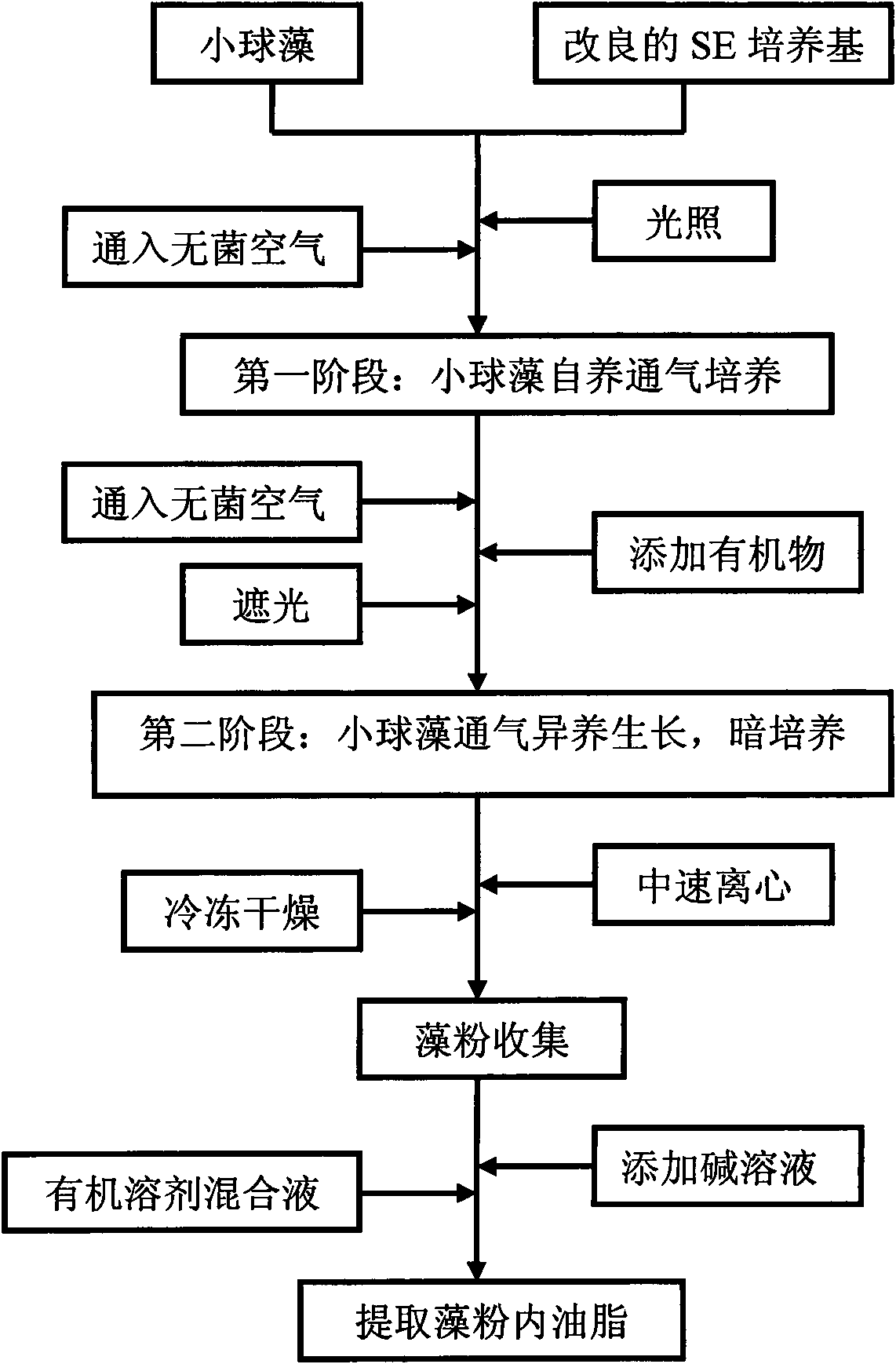

[0024] Embodiment 1 The method flowchart (refer to figure 1 )

[0025] 1. The first-stage aerated autotrophic culture method of microalgae is as follows: the microalgae can be isolated from the environment, and can also be purchased from domestic and foreign algal species banks. In this example, Chlorella is taken as an example, and Chlorella cells are cultivated in a modified SE liquid medium at a temperature of 25-27°C and a light of 120 μmol m -2 ·s -1 , culture time 4-5 days. The composition of the improved SE liquid medium is characterized by the following: each 1000mL medium contains NaNO 3 0.25g, CaCl 2 .2H 2 O 0.025g, MgSO 4 ·7H 2 O 0.075g, K 2 HPO 4 0.075g, KH 2 PO 4 0.175g, NaCl 0.025g, FeCl 3 ·6H 2 O 0.005g, Fe-EDTA 2mL, A5 trace element mixture 1mL.

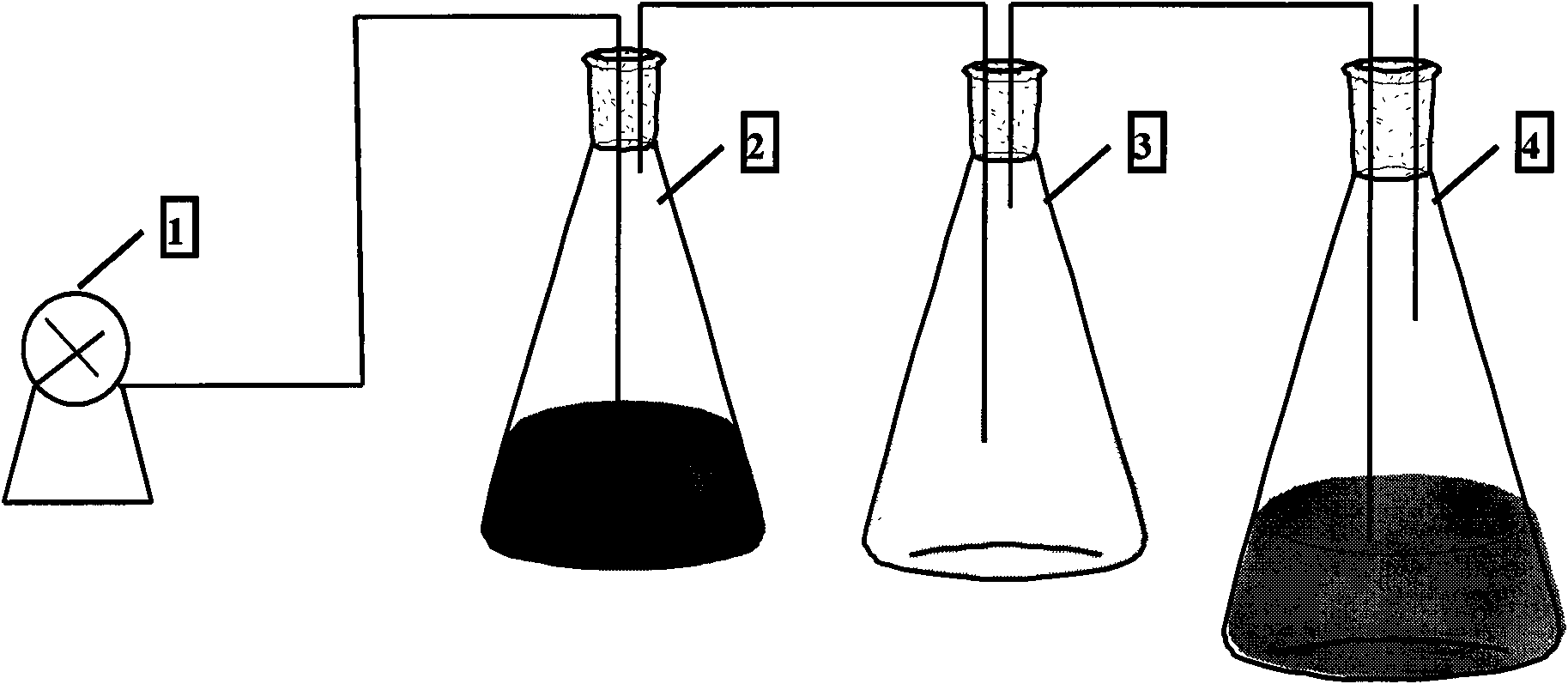

[0026] 2. The chlorella aseptic aeration expansion culture method is: refer to figure 2 As shown, use a magnetic air compression pump to pass 1% copper sulfate solution to sterilize, then remove tra...

Embodiment 2

[0030] Embodiment 2. The specific steps of the rapid accumulation of oil in the mixed nutrient aseptic culture of chlorella in this embodiment are as follows:

[0031] 1. Steps of the first-stage aerobic autotrophic culture method of chlorella: the chlorella comes from the environment and is separated and purified by streaking on a plate. First enrich and cultivate algae cells in 50mL modified SE liquid medium, and after 4-5 days of culture, streak the enriched algae cells on the plate of SE solid medium, in which the amount of agar is 2.0%, and the culture temperature is 25-27°C , light 120μmol·m -2 ·s -1 . After about 2 weeks, a single green algae colony grows on the solid plate, and the single algae colony is picked and placed on the SE solid medium plate to be streaked and separated twice to obtain pure algae species. The composition of the improved SE liquid medium is characterized by the following: each 1000mL medium contains NaNO 3 0.25g, CaCl 2 .2H 2 O 0.025g, M...

Embodiment 3

[0036] Embodiment 3 gets 3 parts of algae powders to extract chlorella oil respectively with chloroform-methanol method, n-hexane-ethanol method and potassium hydroxide-methanol method in addition, and this embodiment mainly compares the extraction effect of each method (reference Figure 5 ).

[0037] 1. The potassium hydroxide-methanol method for oil extraction: Take 0.3g of chlorella algae powder and add a little distilled water, freeze at -20°C and dissolve in water at 40°C for 5min, repeat twice. Add 4mL of 1M potassium hydroxide-methanol mixture to the algae powder treated by freeze-thaw method, bathe in water at 75°C for 10min, add 2mL of n-hexane, mix well, centrifuge at 4000r / min for 10min, take the supernatant, add n-hexane to wash the residue , combined supernatants, weighed in volatile solvent at 60°C, and calculated oil content according to the following formula: total fat percentage (%)=(total fat content / dry weight of algae cells)×100%. The potassium hydroxide-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com